When missiles pierce the sky, radars scan vast distances, and warships cut through waves, the “power source” of these steel beasts is the seemingly unremarkable yet crucial power semiconductor devices.

Harsh Military Environments: Commercial Devices Struggle

-

Extreme Temperatures: The surface of missiles reaches extremely high temperatures when crossing the atmosphere, while polar equipment faces -50℃ severe cold, causing ordinary chips to fail instantly.

-

Strong Radiation Interference: In electronic warfare environments, strong electromagnetic pulses can burn out commercial chips, and nuclear radiation environments require special protection.

-

Severe Shock and Vibration: The continuous vibrations from tank off-roading and aircraft maneuvers far exceed the limits of consumer electronics.

The ‘Hardcore Strength’ of Military Power Semiconductors

-

Material Innovation – Silicon Carbide (SiC) Breakthrough

-

Traditional silicon-based IGBTs experience a sharp drop in efficiency at high temperatures, while SiC devices maintain over 90% efficiency in 200℃ environments, reducing energy consumption by 30%. A new phased array radar using SiC modules has increased detection range by 15% and reduced the cooling system size by 40%.

-

Radiation-Hardened Design Utilizing special well structures, shielding layers, and error correction circuits, radiation resistance has improved by over 100 times. MOSFETs in satellite power systems can operate stably for 15 years in strong radiation environments.

-

Super Strong Packaging Protection Metal-ceramic packaging withstands extreme temperature differences from -55℃ to +200℃, with a shock resistance rating exceeding 50G (equivalent to withstanding an impact force 50 times its own weight). A certain armored vehicle’s drive module has passed continuous off-road testing without failure.

The ‘Heart’ Applications of Cutting-Edge Equipment

-

Electromagnetic Cannons and Laser Weapons: Megawatt-level pulse power supplies require ultra-high voltage IGBTs, with instantaneous currents reaching millions of amperes during firing.

-

All-Electric Propulsion Warships: Integrated power systems rely on large-capacity IGBT modules, with a single ship’s power exceeding 20MW (equivalent to 20,000 household air conditioners).

-

Multi-Electrification Systems in Fighter Jets: The F-35’s fly-by-wire control and electrical control systems result in power semiconductor usage being more than three times that of traditional fighter jets.

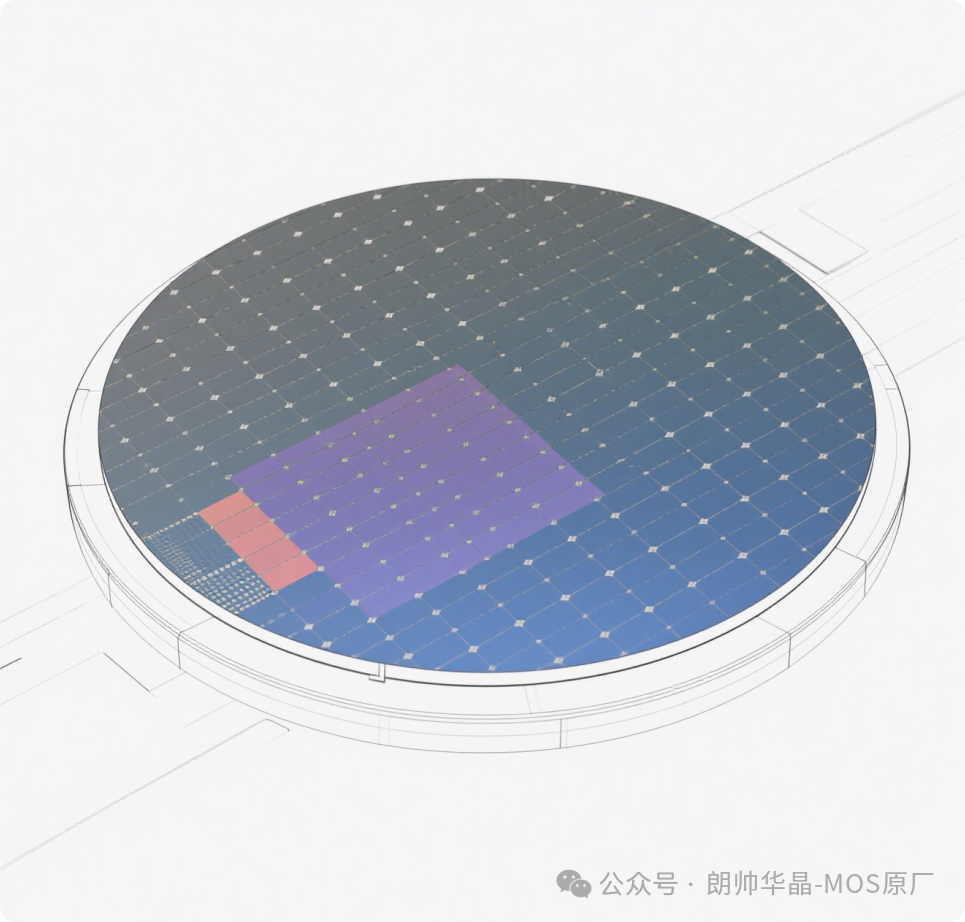

Accelerating Localization: The ‘Chinese Chip’ of National Defense The West has long blocked military-grade high-reliability power devices. China has achieved mass production of 6500V high-voltage IGBTs, with SiC MOSFETs breaking through 1200V voltage ratings, and a certain new destroyer’s power system has over 90% of its chips sourced domestically.

Expert Opinion “Power semiconductors are like the ‘muscle fibers’ of modern military industry,” said Zhang Ming, chief engineer at China Electronics Technology Group, “Their performance directly determines the mobility, lethality, and survivability of equipment. Self-control has risen to a strategic security level.”

In the future, as GaN (Gallium Nitride) devices mature and three-dimensional packaging technologies are applied, smaller size and higher power density ‘super chips’ will help push new generation equipment such as hypersonic weapons and directed energy weapons beyond physical limits.

Power semiconductors, though hidden within steel shells, drive the heavy machinery of great powers with surging electrical energy, silently guarding every inch of the homeland. Lang Shuaihua Jing with Chinese chips, safeguarding the nation’s brilliance.