Industrial IoT Data Acquisition: Practical Experience Sharing on S7-1500

Hello everyone, I am an engineer with 15 years of experience in industrial automation, mainly responsible for projects related to industrial IoT and data acquisition. Today, I would like to share my practical experience in using the Siemens S7-1500 PLC for data acquisition.

Why Focus on This Topic?

With the advancement of Industry 4.0, equipment data acquisition has become a fundamental requirement for smart manufacturing. Many engineering colleagues may also be troubled by how to efficiently collect PLC data. This article will combine my project experience to help everyone quickly grasp the key technologies for S7-1500 data acquisition from a practical perspective.

Hardware Preparation

First, let’s introduce the basic hardware configuration:

- S7-1500 PLC (recommended model 1515 or higher)

- Ethernet switch

- Industrial computer or server

- Several network cables

Tip: It is recommended to choose a gigabit switch, as a hundred megabit may become a bottleneck when the data volume increases later. I learned this lesson the hard way in one of my projects.

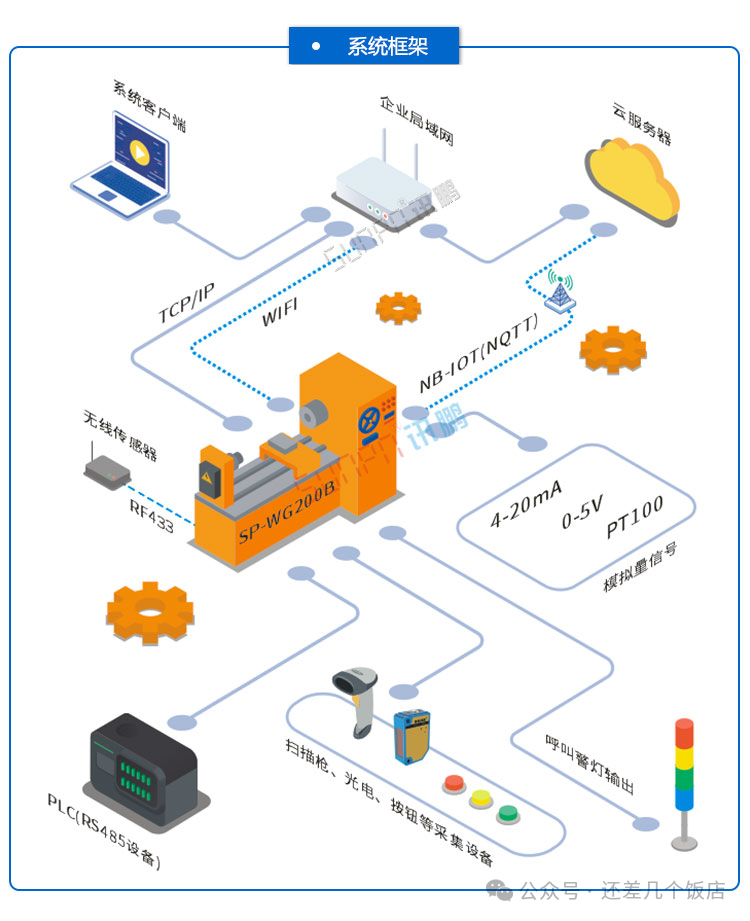

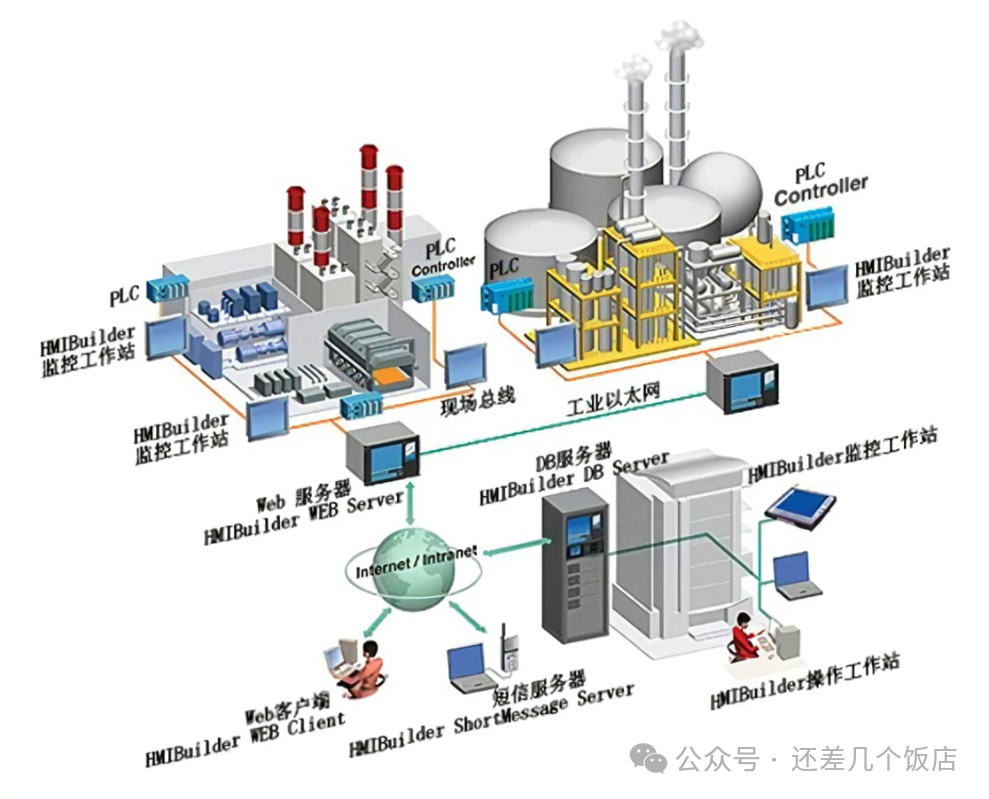

Communication Architecture Design

In my practice, I recommend the following architecture:

- PLC as the data source

- Middleware as the data acquisition layer

- Database as the storage layer

- Application layer responsible for display and analysis

Important reminder: Be sure to plan the network properly! I have encountered cases where improper subnet planning led to communication conflicts.

Core Technology Implementation

1. PLC Program Preparation

First, you need to create a data block (DB) in the PLC:

DATA_BLOCK "Production_Data"

{ S7_Optimized_Access := 'TRUE' }

VERSION : 0.1

NON_RETAIN

STRUCT

Temperature : Real; // Temperature

Pressure : Real; // Pressure

Speed : Int; // Speed

Status : Bool; // Device Status

TimeStamp : DTL; // Timestamp

END_STRUCT;

BEGIN

Temperature := 25.0;

Pressure := 1.0;

Speed := 0;

Status := FALSE;

END_DATA_BLOCK

2. Communication Program Development

We developed the acquisition program using C#:

using Sharp7;

using System;

public class DataCollector

{

private S7Client client;

public DataCollector()

{

client = new S7Client();

}

public bool Connect(string ip)

{

int result = client.ConnectTo(ip, 0, 1);

return result == 0;

}

public ProductionData ReadData()

{

byte[] buffer = new byte[32];

client.DBRead(1, 0, buffer.Length, buffer);

return new ProductionData

{

Temperature = S7.GetRealAt(buffer, 0),

Pressure = S7.GetRealAt(buffer, 4),

Speed = S7.GetIntAt(buffer, 8),

Status = S7.GetBitAt(buffer, 10, 0)

};

}

}

Do you need me to explain this piece of code?

Practical Application Case

I applied this solution in a brewery project, mainly collecting the following data:

- Production line speed

- Device temperature

- Pressure data

- Production statistics

- Device status

The results were excellent, helping the client achieve:

- Real-time monitoring of production status

- Early warning of abnormal situations

- Analysis of production efficiency

- Traceability of quality issues

Common Problems and Solutions

- Data disconnection issues

- Cause: Unstable network or high PLC load

- Solution: Implement an automatic reconnection mechanism and set a reasonable acquisition cycle

- Data accuracy deviation

- Cause: Data type conversion issues

- Solution: Pay attention to the reading method of REAL type data

- Time synchronization issues

- Cause: PLC and server time are not synchronized

- Solution: Use a unified NTP server

Debugging Tips

Here are some practical debugging methods:

- Use Wireshark to analyze communication data

- Monitor data blocks online in TIA Portal

- Log abnormal situations

Tip: It is recommended to keep logs during the development phase, making it easier to locate issues when they arise.

Project Experience Summary

- Performance Optimization

- Set a reasonable acquisition cycle

- Batch reading instead of single-point reading

- Use data caching appropriately

- Reliability Improvement

- Implement reconnection on disconnection

- Data verification mechanism

- Exception handling mechanism

- Scalability Considerations

- Reserve configuration interfaces

- Modular design

- Standardized data format

Insights and Reflections

Through the practice of multiple projects, I deeply feel that industrial IoT data acquisition is not only a technical issue but also requires consideration of practical application scenarios. I suggest everyone during development:

- First, clarify requirements and understand the business

- Plan the architecture reasonably

- Focus on code quality

- Emphasize exception handling

- Maintain good documentation

Finally, I welcome everyone to share your experiences and thoughts in the comments section. If you have any questions, feel free to communicate, and let’s improve together!

Future Outlook

With the development of 5G technology and the popularity of edge computing, data acquisition technology will continue to evolve. I suggest everyone keep an eye on:

- TSN technology applications

- OPC UA protocol

- Edge computing solutions

- Integration with artificial intelligence

Let’s grow together in the wave of industrial IoT and contribute to smart manufacturing!