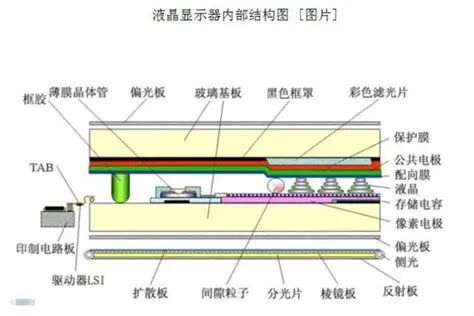

Liquid Crystal Display (LCD) dominates the current electronic display field due to its advantages of being lightweight, energy-efficient, and providing clear displays, widely used in various electronic devices.

Power electronics technology plays an indispensable role in enhancing the performance and functionality of LCDs as a key branch of modern electronic technology.

By efficiently converting, controlling, and managing electrical energy, power electronics technology lays a solid foundation for the stable operation, image quality optimization, and energy utilization efficiency of LCDs.

Image from the internet

01Application of Power Electronics Technology in LCD Power Supply Systems01Application of Switching Power Supplies in LCDs

Switching power supplies have become the preferred solution for LCD power supply systems due to their significant advantages of high efficiency, compact size, and lightweight.

Their operating principle is based on the high-frequency switching action of power semiconductor devices, achieving precise output voltage regulation by controlling the ratio of the on-time to off-time of the switching transistor (i.e., duty cycle).

In LCDs, switching power supplies convert mains electricity (typically 220V AC) into DC voltages suitable for the internal circuits of the display, such as 12V, 5V, etc.

The core components of a switching power supply include input filtering circuits, rectification circuits, DC-DC conversion circuits, output filtering circuits, and control circuits.

The input filtering circuit is used to filter out noise and interference from the mains supply, preventing it from affecting subsequent circuits; the rectification circuit converts AC to DC; the DC-DC conversion circuit uses a high-frequency transformer to step up or step down the voltage, and utilizes PWM (Pulse Width Modulation) or PFM (Pulse Frequency Modulation) technology to precisely control the output voltage;

The output filtering circuit further smooths the output voltage, reducing ripple and providing a stable, clean DC power supply for the LCD. The control circuit monitors the output voltage and current in real-time, adjusting the operation of the switching transistor based on feedback signals to ensure the stable operation and high efficiency of the power supply system.

Compared to traditional linear power supplies, switching power supplies can achieve efficiencies of 80% – 95%, significantly reducing energy consumption and heat generation.

Additionally, due to the use of high-frequency switching technology, the size of transformers and filtering components can be greatly reduced, making the power supply system more compact and lightweight, meeting the design requirements for thinner LCDs.

Image from the internet

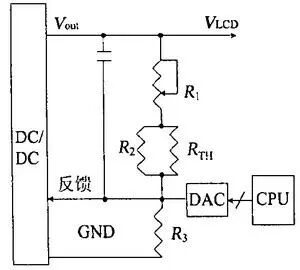

02Functions and Roles of Power Management Chips

Power management chips play a key role in the intelligent management and control of LCD power supply systems.

They integrate various functional modules, such as voltage conversion, current detection, over-voltage protection, over-current protection, under-voltage protection, and power sequencing control, enabling comprehensive monitoring and management of the power supply system.

Taking a common LCD power management chip as an example, it integrates multiple DC-DC converters internally, providing various stable voltage outputs for different parts of the LCD simultaneously. Through internal feedback control circuits, the chip can monitor changes in output voltage and current in real-time and automatically adjust based on preset thresholds, ensuring the stability and accuracy of the output voltage. During the startup process of the LCD, the power management chip can precisely control the power-up sequencing of each part, avoiding circuit damage or display anomalies caused by improper power sequencing.

Power management chips also have comprehensive protection functions. When detecting over-voltage, under-voltage, or excessive current, the chip will immediately take protective measures, such as shutting down power output or adjusting output voltage, to protect the LCD circuit from damage, enhancing the reliability and stability of the system.

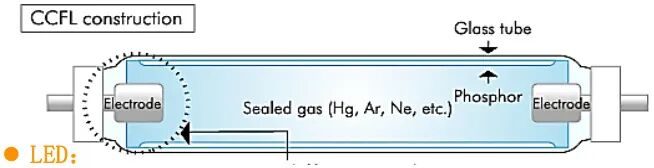

02Application of Power Electronics Technology in LCD Backlight Source Driving01Cold Cathode Fluorescent Lamp (CCFL) Driving Circuits

In early LCDs, Cold Cathode Fluorescent Lamps (CCFL) served as the primary backlight source, and their driving circuits needed to convert DC voltage into high-frequency AC high voltage to ignite the CCFL and maintain stable operation.

CCFL driving circuits typically use DC-AC conversion technology, with common topologies including half-bridge inverter circuits and full-bridge inverter circuits.

For example, in a half-bridge inverter circuit, it mainly consists of two switching transistors, two capacitors, and a high-frequency transformer. The DC power supply is divided by the two capacitors and applied between the source and drain of the two switching transistors. The control circuit alternates the conduction and cutoff of the two switching transistors using PWM signals, generating high-frequency alternating voltage across the primary winding of the transformer, which is stepped up by the transformer to output high-frequency AC high voltage at the secondary winding to ignite the CCFL.

To achieve brightness adjustment of the CCFL, the driving circuit typically employs PWM dimming or analog dimming methods. PWM dimming adjusts the average input power to the CCFL by changing the duty cycle of the PWM signal, while analog dimming adjusts brightness by changing the operating current of the CCFL.CCFL driving circuits also need to have over-voltage protection, over-current protection, and open-circuit protection functions to ensure the safe operation of the CCFL under various abnormal conditions.

Image from the internet

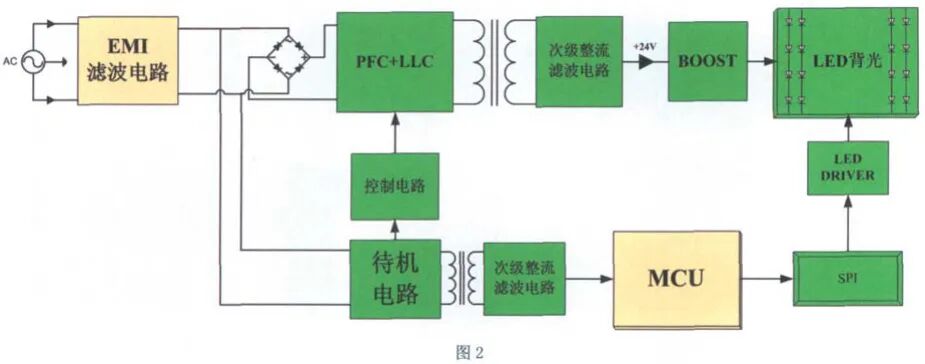

02LED Backlight Source Driving Technology

In recent years, with the rapid development of Light Emitting Diode (LED) technology, LED backlight sources have gradually replaced CCFLs as the mainstream choice for LCD backlighting due to their energy-saving, long lifespan, high brightness, fast response speed, and wide color gamut.

LED backlight source driving technology mainly adopts constant current driving methods to ensure that each LED operates under stable current, thereby ensuring consistency and stability in LED brightness.

LED driving circuits typically use DC-DC conversion technology, with common topologies including buck circuits, boost circuits, buck-boost circuits, and linear constant current driving circuits. Buck circuits are suitable for situations where the input voltage is higher than the series voltage of the LEDs, reducing the input voltage to an appropriate LED driving voltage while maintaining a constant output current; boost circuits are used when the input voltage is lower than the series voltage of the LEDs, increasing the input voltage to meet the operating voltage of the LEDs; buck-boost circuits can flexibly achieve voltage conversion based on the relationship between input voltage and LED operating voltage.

Linear constant current driving circuits utilize the principle of linear voltage regulators to achieve precise control of LED current by adjusting the conduction resistance of transistors. Although linear constant current driving circuits are simple in structure and relatively low in cost, their efficiency is relatively low, making them suitable for small LCD applications where efficiency is not a high priority. To improve the efficiency and performance of LED driving circuits, modern LED driver chips typically integrate various functions, such as PWM dimming, over-voltage protection, over-current protection, and over-temperature protection.

Image from the internet

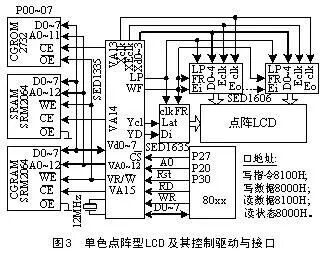

03Application of Power Electronics Technology in Signal Processing and Control Circuits01Application of Power Electronics Devices in LCD Panel Driving Circuits

LCD panel driving circuits are responsible for converting input video signals into driving voltage signals suitable for the deflection of liquid crystal molecules to achieve image display. In driving circuits, power electronic devices such as MOSFETs and IGBTs (Insulated Gate Bipolar Transistors) play a crucial role.

For example, in row driving circuits, a switching matrix composed of multiple MOSFETs is typically used to apply row scanning signals sequentially to the row electrodes of the LCD panel by controlling the conduction and cutoff of the MOSFETs. MOSFETs have high-speed switching characteristics and low on-resistance, enabling fast and accurate switching of row scanning signals, ensuring the precision and stability of image row scanning.

In column driving circuits, MOSFETs are also used to achieve high-speed switching and transmission of column data signals, accurately applying the analog voltage signals after digital-to-analog conversion to the column electrodes of the LCD panel, controlling the deflection angle of liquid crystal molecules to present different gray levels and colors.

IGBTs are applied in some driving circuits that need to handle larger power, such as driving high-resolution, large-size LCD panels. IGBTs combine the high input impedance of MOSFETs with the low on-state voltage drop characteristics of bipolar transistors, capable of withstanding higher voltages and currents, providing stable and reliable driving power for large-size LCD panels.

Image from the internet

02Role of Power Electronics Technology in LCD Control Circuits

In the control circuits of LCDs, power electronics technology is used to achieve precise control and adjustment of various functions of the display. Through PWM technology, precise adjustment of backlight brightness is achieved, stable operating voltage is provided to control chips through DC-DC conversion circuits, and high-speed control of signal transmission and switching is realized using power electronic devices.

In the power management control of the display, power electronics technology can intelligently control the on/off and power output of the power supply based on the operating state of the display (such as power on, power off, standby, sleep, etc.). In standby mode, the power output is reduced by controlling the operating mode of the switching power supply to achieve energy-saving purposes; at the moment of power-on, precise control of the power-up sequencing and voltage rise rate ensures that all parts of the display circuit can start normally, avoiding circuit damage caused by voltage spikes.

In terms of signal processing and transmission, power electronic devices such as high-speed switching diodes and MOSFETs are used to achieve rapid switching and transmission of video signals, ensuring the real-time and accuracy of image signals.

In the implementation of multi-screen splicing, picture-in-picture, and other functions of the display, power electronics technology achieves synchronous display and flexible layout of different video signals on the same display through precise control of signal routing and switching.

Image from the internet

04Conclusion

Power electronics technology runs through various key aspects of LCDs, including power supply systems, backlight driving, signal processing, and control, playing a crucial role in enhancing the display quality, stability, energy efficiency, and achieving energy conservation and environmental protection.

With the continuous advancement of technology, power electronics technology will continue to innovate and develop, bringing higher performance improvements and more functional expansions to LCDs.

Electronic Technology Communication Group Long press to recognize the QR codeto communicate and learn with partners in the industry

Electronic Technology Communication Group Long press to recognize the QR codeto communicate and learn with partners in the industry

Scan the QR code above to receive 【free resources】

Scan the QR code above to receive 【free resources】

All articles, images, videos, and materials published by this public account (hereinafter referred to as “content”) are fortechnical communication and knowledge sharing, and do not represent any official position or professional advice. The content may contain personal opinions or industry analysis, and readers should refer to it cautiously based on their own needs.

Like, remember to like + view + share + comment, support itIt’s all here, isn’t it nice to click me?