“PLC Fault Isolation: A Three-Level Protection Mechanism Reduces Production Line Downtime by 80%!”

Dear friends in the industrial control community, today we are going to discuss a hardcore yet practical topic! Have you ever encountered a frustrating moment—when a sensor in the workshop malfunctions, causing the entire PLC system to crash, resulting in an 8-hour production line shutdown? Isn’t that infuriating? It’s like a fly falling into a hot pot, ruining a whole pot of good soup!

▶ A Bloody Lesson

Last year, at a chemical plant, an overheating motor alarm failed to stop the issue, resulting in the destruction of three frequency converters, leading to a direct loss of 1.5 million! Even worse, at an automotive factory, a poorly connected ground wire caused signal chaos, leading to a robot unexpectedly crashing into the assembly line, with repair costs enough to buy a BMW 5 Series! This isn’t just equipment failure; it’s a money shredder!

Do you know where the problem lies? Our PLC system is too “loyal”! It’s like one roommate catching a cold, and the whole dormitory ends up with a fever. The traditional control architecture is like a large dormitory, where fault currents and signal interference are like “viruses” running rampant, making it hard to avoid infection!

It’s time to put a “protective suit” on the PLC! Today, I will teach you a three-level protection mechanism to keep faults isolated!

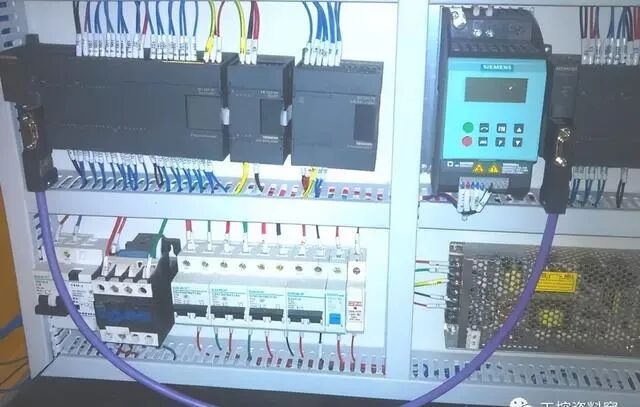

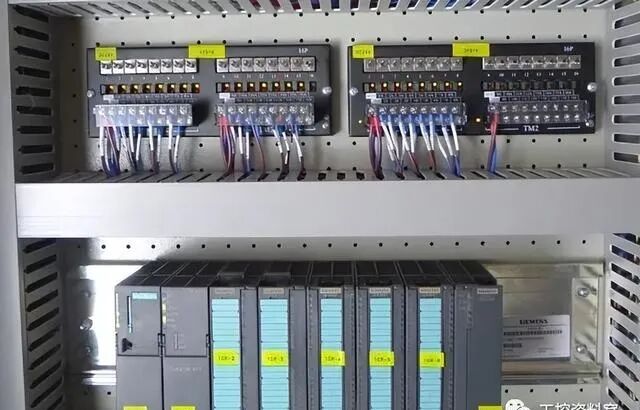

▶ First Level: Physical Isolation (Hardware Protection)

Imagine creating firebreak zones for the production line—

Power Distribution: Key equipment has independent circuit breakers, like installing independent power switches in a VIP room.

Signal Isolation: Analog channels are equipped with isolation modules, and signal lines are fitted with magnetic rings, tighter than a gas mask.

Area Blockade: High-risk equipment is placed in a safety island; fault currents trying to escape? No way!

Data from a food factory shows: after installing isolation barriers, downtime caused by grounding faults dropped from an average of 6 times a month to zero!

▶ Second Level: Logical Isolation (Software Protection)

This requires some black technology—

Heartbeat Monitoring: Each subsystem is equipped with a “smart wristband” that detects anomalies within 2ms and immediately cuts power.

Safety Loop: Key control points are set with dual-channel verification, more reliable than a bank USB security token.

Data Firewall: The OPC UA protocol manages data flow; interference signals trying to sneak in? They must pass security checks first!

A lithium battery company has taken it a step further: they have integrated a “fault prediction model” into their AI algorithms, locking down abnormal modules 20 minutes in advance, preventing faults before they even surface!

▶ Third Level: Intelligent Isolation (System Protection)

The ultimate protection requires a “combination punch”—

Dynamic Partitioning: Automatically divides isolation zones based on production status, more adaptable than Transformers.

Self-Healing Network: Uses a ring topology structure, automatically switching paths when a line is broken, effectively a PLC version of “network reconnection”.

Digital Twin: Real-time mirroring of operational data, with fault drills conducted in a virtual space, keeping the production line stable as a rock.

Check out this comparative data and you’ll understand:

▶ Pitfall Guide (Lessons Learned)

❗ Never skimp on isolation modules! A factory that tried to save money by using ordinary relays ended up with all equipment dancing disco during thunderstorms.

❗ Safety loops must have independent power supply! The most reckless operation I’ve seen: safety circuits and control circuits sharing a power supply, resulting in explosive sparks.

❗ Grounding isn’t just about connecting a wire! Remember the “three no principles”: different voltage levels should not share ground, digital/analog signals should not share ground, and strong/weak currents should not share ground.

Now let’s test everyone: how would you handle these situations?

The conveyor suddenly accelerates, but the PLC shows normal speed.

Analog signals go haywire at night but are normal during the day.

The IO module indicator lights are still flashing after the equipment is turned off.

(The first three friends to answer correctly in the comments will receive a digital version of “Industrial Site Interference Prevention Secrets”!)

Finally, here’s a golden quote: In the era of smart factories, the best defense isn’t just reacting to attacks, but preventing faults from ever getting out! What do you think of this “isolation strategy”? Hurry up and implement it in your workshop; next month, your maintenance colleagues might just be sitting idle, snacking on sunflower seeds!