1. Importance of Monitoring Icing on Wind Turbine Blades

Icing on wind turbine blades is one of the significant technical challenges faced in the wind power generation field. In low-temperature and high-humidity environments, ice layers can easily form on the blade surfaces, directly leading to the following issues:

1. Decreased power generation efficiency: Icing alters the aerodynamic profile of the blades, increases surface roughness, and reduces wind energy conversion efficiency. Research shows that when the ice layer thickness reaches 10mm, power generation can drop by more than 30%.

2. Risk of mechanical damage: The impact force from ice shedding can reach 100 km/h, leading to cracks or even breakage of the blades. For example, a wind farm once experienced blade breakage due to icing, resulting in repair costs exceeding one million yuan.

3. Safety hazards: Falling ice blocks may threaten the safety of surrounding personnel and equipment. For instance, in 2018, falling ice from a wind farm caused a traffic accident.

4. Increased operation and maintenance costs: Traditional manual inspections are inefficient and risky, especially in severe weather conditions, making it difficult to monitor icing dynamics in real-time.

Therefore, developing a high-precision, low-risk online monitoring system is urgently needed to enhance the safety and economic efficiency of wind power operations.

2. Icing Monitoring Principles and Technical Solutions

(1) Monitoring Principles

This solution employs the JCF-1610 wind turbine blade icing monitoring sensor, whose core technology is microwave disturbance detection and environmental parameter fusion analysis:

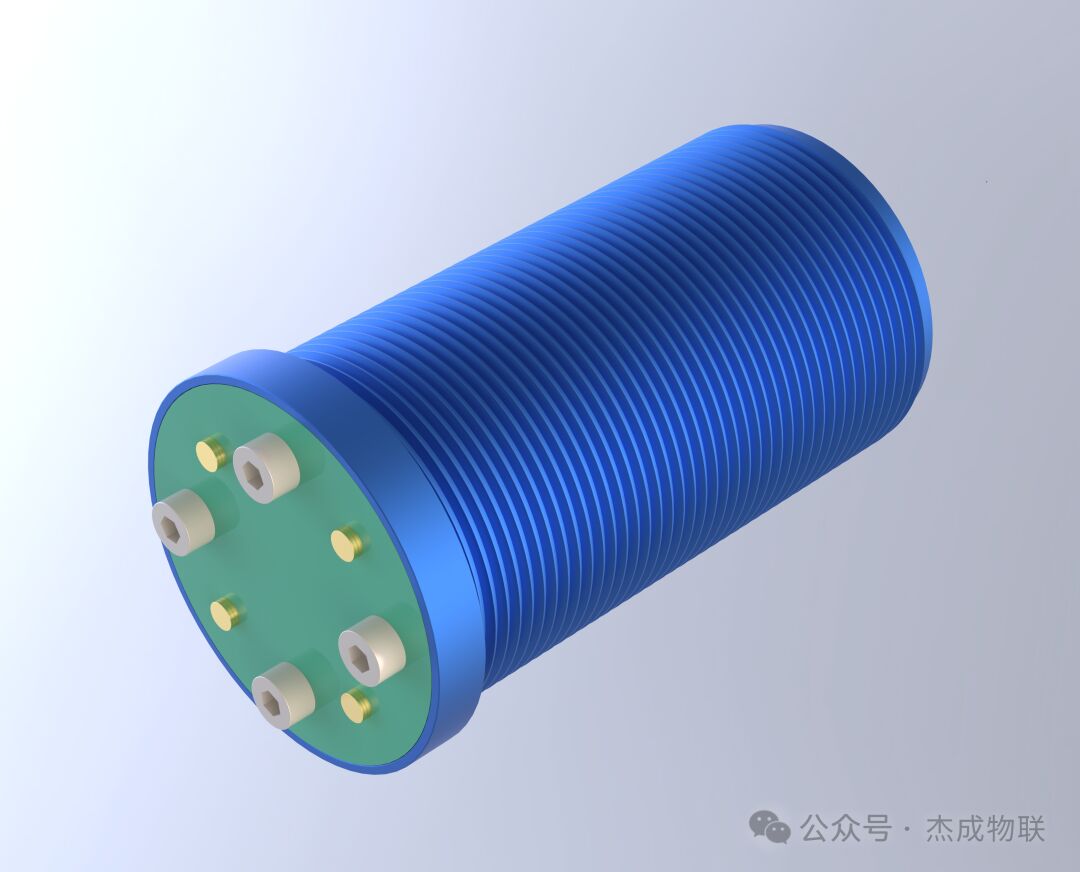

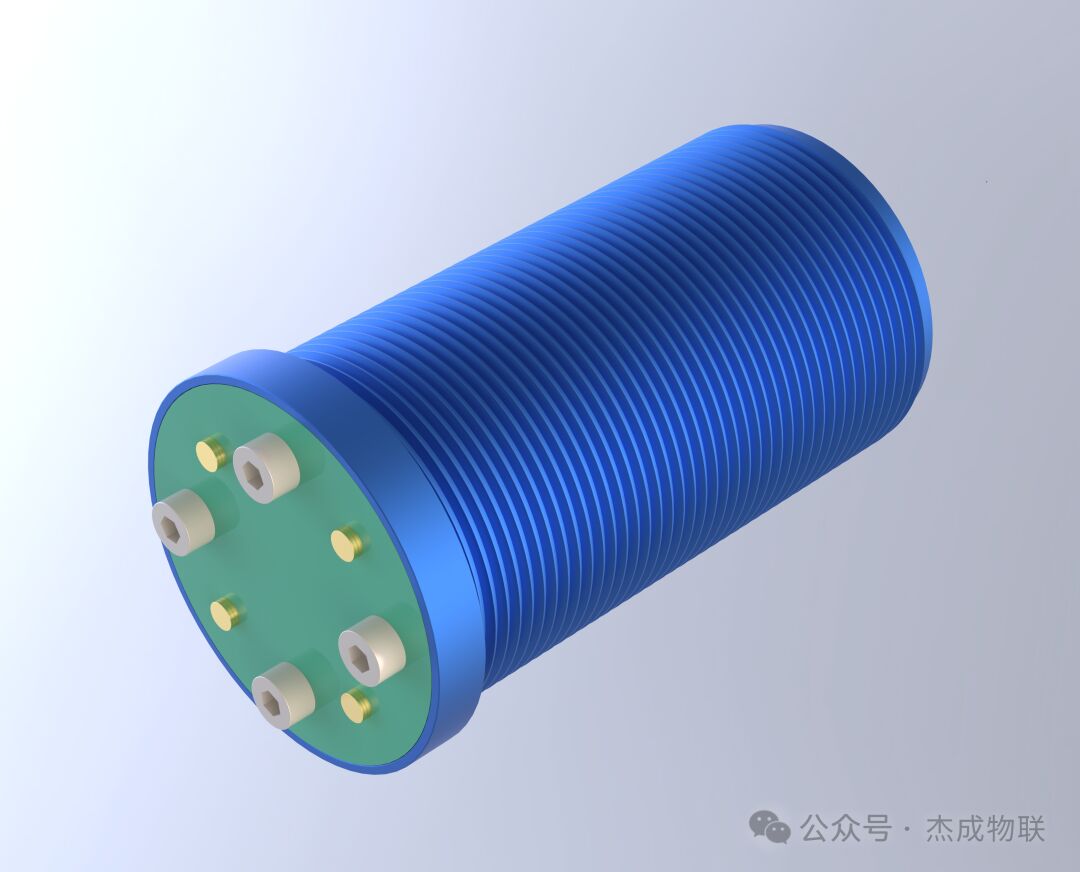

JCF-1610 Wind Turbine Blade Icing Monitoring Sensor

1. Microwave disturbance technology: The sensor emits microwave signals and analyzes the differences in reflection characteristics of ice, water, and air to calculate icing thickness in real-time (range 0.2~8mm, resolution 0.1mm). When an ice layer forms, the absorption intensity and phase change of the microwave signal can accurately reflect the distribution of the ice layer. Compared to traditional image recognition technology (which is severely affected by rain and snow) and tension sensors (which require contact installation), this technology offers non-invasive, all-weather advantages.

2. Environmental parameter compensation: By combining data from temperature, humidity, wind speed, and other parameters (from auxiliary sensors installed on the tower), the Bayesian network model dynamically corrects microwave signal attenuation, eliminating interference from fog, frost, and other factors, improving monitoring accuracy to ±0.1mm.

(2) Technical Advantages

1. Non-contact monitoring: Avoids damage to the blade structure caused by traditional probe sensors.

2. All-weather operation: Adapts to extreme environments from -40℃ to 85℃, resistant to rain, snow, and frost interference.

3. Indirect monitoring logic: By deploying icing monitoring sensor groups at the top of the nacelle and mid-tower (10-15m above ground), environmental parameters of areas prone to icing, such as the nacelle and tower, are monitored to infer the icing trend of the blades, avoiding the complexity of direct installation on the blade surface. Actual tests show that this method has a high accuracy rate for indirect prediction of blade icing and a low false alarm rate.

3. Composition of the Icing Monitoring System

The system consists of a three-tier architecture: perception layer, transmission layer, and platform layer, achieving a complete closed-loop of data collection, transmission, and intelligent analysis.

(1) Perception Layer

1. Core devices:

1.1. JCF-1610 wind turbine blade icing monitoring sensor: Each turbine is equipped with three nodes, embedded at the leading edge 20% chord length (aerodynamic sensitive area), installed at the top of the nacelle (environmental monitoring point), and in the middle of the tower (icing trend observation point).

1.2. Micro-meteorological sensors: Including temperature and humidity sensors, anemometers, optical rain gauges, etc., for environmental parameter collection.

2. Power supply module: Utilizes a solar + battery solution, supporting power supply scenarios in remote areas without grid access.

(2) Transmission Layer

1. Communication technology: Primarily 4G/5G wireless transmission, with LoRa as a backup link, ensuring communication reliability in high-altitude and weak signal areas.

2. Protocol compatibility: Supports IEC 61400-25 standards, allowing direct integration into SCADA systems for collaborative control with the wind turbine master control.

(3) Platform Layer

1. Edge computing nodes: Equipped with advanced chips, performing real-time data cleaning, feature extraction, and short-term predictions (icing risk for the next hour).

2. Cloud analysis platform:

2.1. Icing growth model: Combines historical data and weather forecasts to predict icing risk levels for the next six hours.

2.2. Multi-level early warning mechanism: Sets thresholds for light (0.5mm), moderate (2mm), and severe (4mm) icing, triggering SMS/email alerts.

2.3. Visualization dashboard: Displays real-time icing thickness, wind speed heat maps, equipment health status, and other parameters.

4. Sensor Installation and Deployment Plan

(1) Installation Principles

1. Covering key areas: Priority deployment in high-altitude, wind-swept, and historically frequent icing areas of wind turbines.

2. Multi-node redundancy: Each turbine is equipped with one embedded blade sensor and two external tower sensors to enhance data reliability.

3. Anti-interference design: Sensors are placed away from metal structures to avoid microwave signal attenuation.

(2) Installation Methods

1. Embedded installation: Suitable for the blade manufacturing stage.

1.1. Embed the JCF-1610 at the leading edge 20% chord length (icing sensitive area).

1.2. Use epoxy resin encapsulation to ensure it is flush with the blade surface, avoiding aerodynamic performance impact.

2. External installation: Suitable for the operation and maintenance stage.

2.1. Tower deployment: Install adjustable angle brackets on the second platform of the tower (10m above ground), ensuring the monitoring surface has an angle ≤15° with the main wind direction, avoiding turbulent areas.

Case of JCF-1610 Icing Monitoring Sensor Installed on Bracket

2.2. Nacelle deployment: The sensor is fixed to the top lightning protection bracket, with a PTFE radiation shield added to avoid temperature drift caused by direct sunlight.

(3) Debugging and Maintenance

1. Signal calibration: Set baseline values through upper computer software and simulate icing environments to verify sensor response curves.

2. Health management: Monitor sensor impedance changes (normal range 50-200Ω) to predict device aging, enabling predictive maintenance.

3. Periodic inspections: Clean sensor surfaces of contaminants quarterly.

5. Application Benefits and Future Outlook

After deploying this system in a northeastern wind farm in the winter of 2024, the following results were achieved:

1. Safety enhancement: Three severe icing events were warned in advance, guiding early shutdowns to avoid direct losses exceeding five million yuan.

2. Energy efficiency optimization: Through dynamic yaw control, the average daily power generation per unit increased by 18% during icing periods.

3. Reduced operation and maintenance burden: Reduced manual inspection frequency by 70%, saving 1.2 million yuan annually.

In the future, combining drone LiDAR inspections with digital twin technology can create an integrated monitoring network of “air-ground-space,” promoting the wind power operation and maintenance into the intelligent era.

We welcome followers to like, comment, correct, or share.

Contact: 18250846591 (WeChat same number).