This article’s images are sourced from: Getac.

Author | Liu Yadong

In the era of smart manufacturing, mobile automation has become a trend to meet the demands for broader data collection, monitoring, and equipment control.

Today, the widespread use of portable computers and tablets has freed operational and technical personnel from fixed workstations, significantly improving the efficiency of operations and maintenance.

A powerful, rugged, and reliable mobile computer not only brings great convenience to enterprise production operations but also enables facility personnel to efficiently access critical decision-making information, providing an unprecedented user experience for the digitalization and intelligence of manufacturing enterprises.

01

Mobile Automation is Changing Industrial Manufacturing Models

In the field of industrial automation, in recent years, with the rapid iteration and increasing complexity of internal automation and digital systems within enterprises, the application of mobile technology for visualization and data access has surged. From business decisions to process workflows, user interfaces, and proactive maintenance, new uses of mobile devices and applications have fundamentally changed industrial manufacturing models.

Mobile portable tablets/computers have become the “magic tool” for efficiently viewing all business processes in real-time on industrial sites, simplifying operations for manufacturing enterprises, ensuring timely service, management, and maintenance, and making unprecedented use of resources. By adding mobile connectivity, companies can enable personnel at all levels to become data-capable multitaskers:

■ Operational personnel can visualize automated devices and systems anytime, anywhere using mobile devices;

■ Experts can interact with operational personnel across an entire site or multiple sites, even globally;

■ Maintenance technicians can receive alerts and trend notifications indicating faults promptly, allowing for quick responses and objective decision-making;

■ Engineers can also optimize production by analyzing more data…

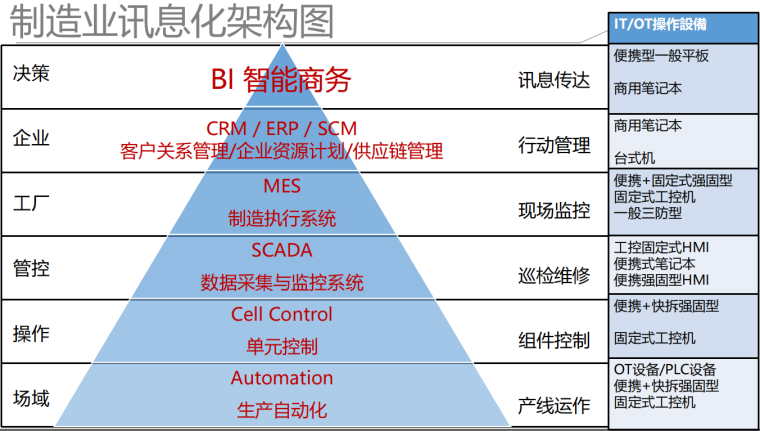

However, within the system architecture of manufacturing enterprises, all IT and OT devices, such as SDACA, Cell Control, DCS, asset management systems, and production automation systems below the MES system, have different operational requirements. The team wants to access various data across systems, which will correspondingly utilize commercial laptops, portable tablets, and desktop computers.

Getac’s China General Manager, Liang Shixi, who has deep roots in the rugged computer field, states that for the vast operational personnel and decision-makers in industrial enterprises, ensuring and improving Utilization Rate, Overall Equipment Effectiveness (OEE), and Production Capacity are the primary concerns. As users’ dependence on mobile workstations deepens, there are higher expectations for the ruggedness, real-time network communication, and security of remote access of mobile computers.

Unlike the laptops people use in daily life, the harsh environments of industrial manufacturing pose severe challenges to the protective performance and reliability of mobile devices. Tablets/computers not only need to meet the demands for work schedules, real-time communication, and data access transmission but also must withstand any weather and harsh environments, which imposes stricter requirements for high availability and reliability of the equipment.

For many years, to steadily enhance the safety, reliability, and efficiency of industrial production and on-site operations, rugged computer manufacturers represented by Getac have been continuously exploring more possibilities for high-speed operation and stable performance, attracting increasing attention from industrial users.

02

Rugged Mobile Computers vs. Three-Proof Machines

In the past, to cope with the varying scenarios and harsh working conditions of industrial applications, companies would equip personnel with “three-proof machines”. However, the basic configurations of some “three-proof machines” on the market have increasingly failed to meet many industries’ specific requirements for drop resistance, antibacterial properties, waterproofing, high and low temperature resistance, surge protection, and corrosion resistance. For example, some three-proof machines can only withstand splashing water, while many enterprises need machines that can handle spraying, rain, and even submersion, raising the protective performance requirements for tablets/computers to a new level.

In industries such as pharmaceuticals, where cleanliness is required, tablets must be fanless and able to withstand high concentrations of alcohol, hydrogen peroxide, or various disinfectants and anti-mold liquids, which places high demands on the surface material and screw corrosion resistance of the machines. Therefore, in recent years, portable rugged tablets or laptops have become the first choice for more and more industrial enterprises due to their many differentiated advantages.

In the food industry, production lines often need to combine SCADA and front-end PLC control, requiring high reliability and low latency wireless network communication that can interconnect with backend data. Rugged computers/tablets can well meet the food industry’s needs for waterproofing, shock resistance, drop resistance, and operation under oil contamination, as well as instrument inspections.

Rugged computers also have typical applications in oil extraction vehicles. Since the vehicles are used for shale oil/gas extraction, mobile devices must be explosion-proof, and rugged tablets can meet users’ communication needs at the main control units of working wells and fracturing equipment, as well as operational control in hydraulic systems and instrumentation systems. They can also perform well in environments with bright light, rain, snow, sunlight, and dust.

In flexible manufacturing production lines with non-fixed workstations and in scenarios that require AR technology/enterprise backend databases, high-resolution cameras, shock and drop resistance in harsh environments, and high-reliability wireless network communication, rugged mobile computers can play a significant role, replacing traditional “three-proof machines” and becoming valuable assistants for enterprise operational personnel.

03

Rugged Computers: More Than Just “Ruggedness”

To ensure the primary task of safe and reliable production, when selecting rugged computers, people will first consider whether the computers can maintain stable performance and simple operation in harsh working environments. However, one often overlooked point is that high product quality and comprehensive after-sales support are both indispensable. Since industrial equipment typically incurs high costs, it is essential to ensure a low return rate, and if any unexpected damage occurs during the warranty period, suppliers must provide free and timely repair services to ensure the return on investment.

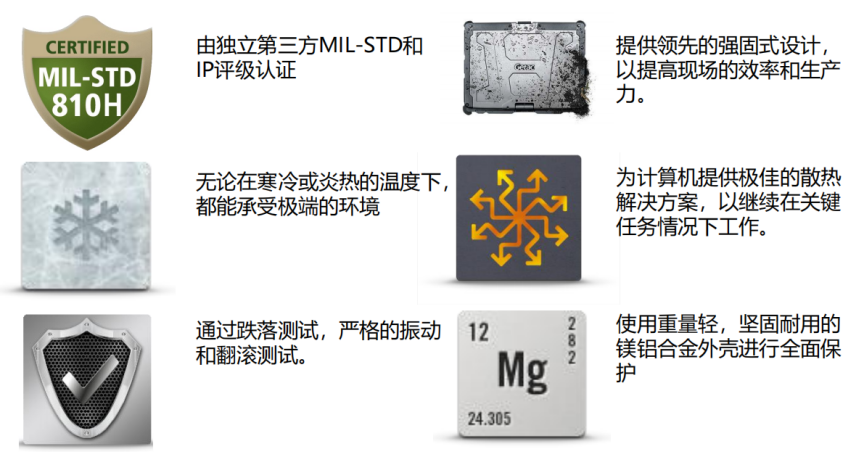

A qualified rugged computer requires a reliable mobile computing platform, precision mechanical components, a lightweight and sturdy alloy shell, and professional industrial design, all backed by strong R&D and manufacturing capabilities. Liang Shixi states that Getac, for example, has over 30 years of technical experience in the rugged computer field, providing rugged servers/tablets, semi-rugged/convertible laptops, and related software and mobile video solutions for clients in defense, public security, firefighting, public utilities, automotive, manufacturing, and logistics industries.

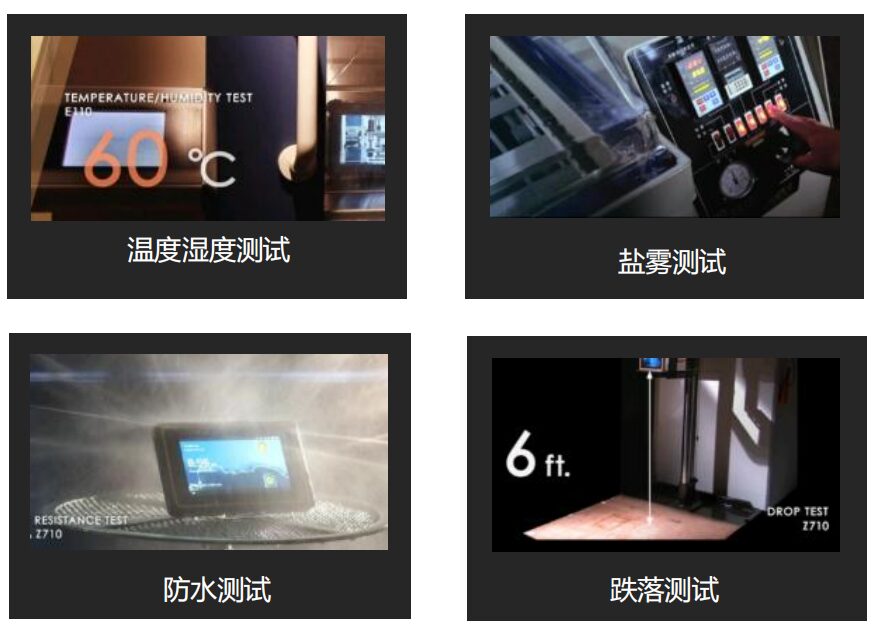

▲Professional Rugged Testing and Certification

Liang Shixi emphasizes that Getac’s products undergo rigorous testing for temperature, waterproofing, salt spray, and drop resistance, possessing global certifications such as IP68 and IP65. Taking the flagship product X600 rugged mobile workstation as an example, the computer is equipped with the 11th generation Intel® Core™ processor, providing excellent performance and response speed, with IP66 certification, a working temperature range of -29°C to 63°C, and multiple functional connection ports, including Thunderbolt™ 4 and docking solutions, capable of meeting the needs of most industrial application scenarios.

▲X600 Rugged Mobile Workstation

In addition to hardware manufacturing, Getac Select® also provides software support including device detection systems, barcode reading programs, safety driving kits, and virtual VGPS kits. Facing various different scenarios, they can also provide battery charging devices, keyboards, various docking stations, and styluses, covering comprehensively, with the one-stop service receiving high customer satisfaction.

▲Getac’s Rich Product Types

In the future, with the continuous advancement of technology and the Internet of Things, the demand for mobile computing devices with different ruggedness levels will gradually increase. In this regard, Liang Shixi states that the mission of rugged computers is not only to solve the ever-changing challenges for users but also to continuously strengthen resilience against lurking cybersecurity threats. Getac’s solutions have always aimed to create peaks of productivity for professionals and are worthy of your trust.

Click

Click “Read Original” to learn more about rugged tablets and products!