1. Characteristics of Automotive Electronic Control Unit Repair

The automotive electronic control unit (ECU) is the core component of various automotive electronic control systems. When faults occur in these systems, many issues may be related to the ECU. However, compared to other components and circuits in the automotive electronic control system, the failure probability of the ECU is relatively low, while the difficulty of detecting ECU faults is relatively high.

It is important to note that when troubleshooting faults in the automotive electronic control system, one should not blindly disassemble the ECU. Instead, the circuits and devices related to the fault phenomenon should be tested first. Only after confirming that all other potential fault areas outside the ECU are normal should the ECU be tested.2. Common Methods for Detecting Automotive ECU Faults

During the troubleshooting process of automotive electronic control system faults, indirect methods such as elimination, voltage detection, and substitution are commonly used to diagnose whether the ECU has faults. However, each of these diagnostic methods has its shortcomings.

01 Elimination Method The elimination method for diagnosing ECU faults begins with analyzing the possible causes of the fault phenomenon in the automotive electronic control system. Then, using appropriate testing methods, the components and circuits that may have faults, excluding the ECU, are checked. If all these potential fault causes are eliminated and the fault phenomenon in the automotive electronic control system still exists, the ECU should then be tested for faults.The elimination method typically employs a voltmeter and an ohmmeter to measure the voltage (when powered) and resistance (when powered off) of the components and circuits connected to the ECU. By evaluating the measured voltage or resistance, one can determine whether the tested circuit or component has a fault. The elimination method is relatively easy to master and is currently one of the more commonly used methods for diagnosing automotive ECU faults.The drawback of the elimination method for repairing automotive ECUs is that it requires testing each component and circuit associated with the ECU one by one. Only when all related components and circuits, excluding the ECU, are confirmed to be normal can one diagnose whether the ECU may have a fault. Thus, it is evident that using the elimination method to diagnose ECU faults can be time-consuming and labor-intensive, and its accuracy is not very high. To confirm whether the ECU has a fault, it usually needs to be used in conjunction with the ECU terminal voltage detection method or the substitution method.02 ECU Terminal Voltage Detection Method The ECU terminal voltage detection method involves using a voltmeter to measure the voltage at the ECU sensor power terminals and the pulse or analog voltage at the actuator control terminals. Based on whether these tested terminals have voltage or whether the measured voltage is within the normal range, one can determine if the ECU has a fault. The ECU terminal voltage detection method is illustrated in Figure 3-29.When the voltage at the ECU power terminals is normal, if the ECU sensor power terminal shows no voltage or abnormal voltage, it can be confirmed that the ECU has a fault. However, if the voltage readings at all terminals are normal, this does not confirm that the ECU is fault-free.The advantage of the ECU terminal voltage detection method is that it can quickly obtain testing data and accurately determine ECU faults based on the measured abnormal data. The disadvantage is that if the results from the relevant terminals are all normal, it still cannot confirm that the ECU is fault-free, necessitating the use of the elimination method or substitution method to verify its condition.03 Substitution Method The substitution method involves replacing the ECU that needs to be tested with a new or confirmed fault-free ECU. If the fault phenomenon disappears, it can be concluded that the original ECU has a fault.The advantage of the substitution method is its simplicity, but its shortcomings are also evident. This method requires a new or confirmed good ECU, which can be difficult or impossible to obtain in some cases. Additionally, if the fault phenomenon does not disappear after substitution, it cannot be concluded that the tested ECU is normal; other methods are usually needed to identify the fault in the electronic control system.3. General Procedure for Detecting Automotive ECU Faults

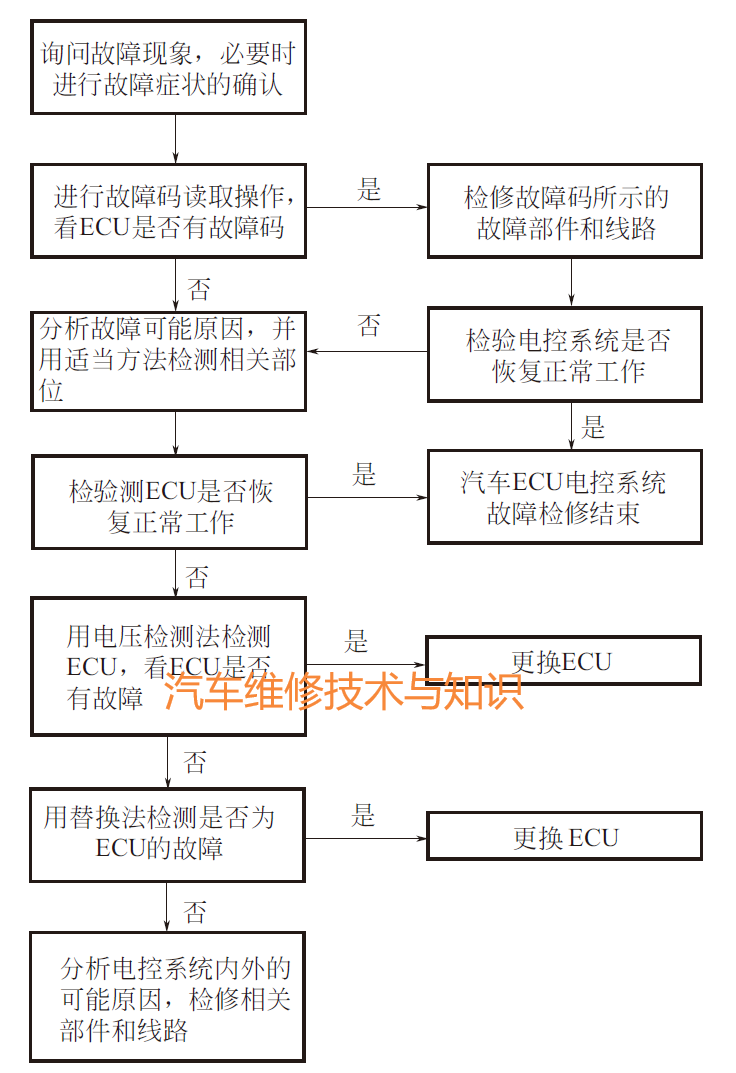

When a fault occurs in the automotive ECU, the fault detection can be carried out according to the procedure shown in the following diagram.

Explanation of the Automotive ECU Fault Detection Procedure:01 First, check the potential fault areas outside the ECU. Although many fault phenomena in automotive ECUs are related to the ECU, the probability of ECU faults is low, and the difficulty of fault detection and confirmation is relatively high. Therefore, during fault repair, potential fault areas outside the ECU should be checked first. When all possible faults related to the sensors, actuators, and their circuits associated with the fault phenomenon are eliminated, and the ECU still cannot return to normal operation, then the ECU should be tested.02 Obtain the fault code. When repairing automotive ECU faults, the first step is to read the fault codes. If there are fault codes, repairs can be made according to the indicated fault locations, making the troubleshooting of the automotive electronic control system accurate and efficient.03 First, use voltage detection to check for ECU faults. When it is necessary to check whether the ECU has a fault, the voltage at the relevant ECU terminals can be checked first. If the measured voltage is abnormal, it can be quickly and accurately determined that the ECU has a fault; if the measured voltage is normal, then consider using the elimination method or substitution method to test the ECU.04 Conduct a comprehensive check of potential fault areas inside and outside the ECU. If the automotive electronic control system still cannot return to normal operation after replacing the ECU, a comprehensive analysis of all possible causes of the fault phenomenon (including those inside and outside the electronic control system) is required, along with relevant testing and repairs.For example, if the engine idles unsteadily or does not idle at low temperatures, in addition to checking the relevant sensors, ECU, and idle control solenoid in the idle control system, do not overlook potential fault causes such as blockage in the idle control solenoid or blockage in the idle air bypass.Similarly, if the vehicle’s brakes fail, in addition to the ABS electronic control system, various causes in the braking system can also lead to this fault. During repairs, these areas and components should not be overlooked. Related Articles more

Explanation of the Automotive ECU Fault Detection Procedure:01 First, check the potential fault areas outside the ECU. Although many fault phenomena in automotive ECUs are related to the ECU, the probability of ECU faults is low, and the difficulty of fault detection and confirmation is relatively high. Therefore, during fault repair, potential fault areas outside the ECU should be checked first. When all possible faults related to the sensors, actuators, and their circuits associated with the fault phenomenon are eliminated, and the ECU still cannot return to normal operation, then the ECU should be tested.02 Obtain the fault code. When repairing automotive ECU faults, the first step is to read the fault codes. If there are fault codes, repairs can be made according to the indicated fault locations, making the troubleshooting of the automotive electronic control system accurate and efficient.03 First, use voltage detection to check for ECU faults. When it is necessary to check whether the ECU has a fault, the voltage at the relevant ECU terminals can be checked first. If the measured voltage is abnormal, it can be quickly and accurately determined that the ECU has a fault; if the measured voltage is normal, then consider using the elimination method or substitution method to test the ECU.04 Conduct a comprehensive check of potential fault areas inside and outside the ECU. If the automotive electronic control system still cannot return to normal operation after replacing the ECU, a comprehensive analysis of all possible causes of the fault phenomenon (including those inside and outside the electronic control system) is required, along with relevant testing and repairs.For example, if the engine idles unsteadily or does not idle at low temperatures, in addition to checking the relevant sensors, ECU, and idle control solenoid in the idle control system, do not overlook potential fault causes such as blockage in the idle control solenoid or blockage in the idle air bypass.Similarly, if the vehicle’s brakes fail, in addition to the ABS electronic control system, various causes in the braking system can also lead to this fault. During repairs, these areas and components should not be overlooked. Related Articles more

- Not understanding automotive electronic control systems makes it hard to call oneself a mechanic.

- How to use a multimeter to check if the electronic control unit (ECU) has faults.

- EFI, EGR, ISC, EBD, ESP… and their respective functions.

- A comprehensive overview of the internal structure and functional modules of automotive computer ECUs.

- Fault analysis of engine system actuators: ignition coil.

- Types of faults in electronic control units (ECUs), their causes, detection procedures, and solutions.

- How to diagnose various engine faults through intake manifold vacuum levels.

- A comprehensive list of the structure, installation positions, and uses of various automotive sensors.

Click below “Read the original article” to learn more!

Click below “Read the original article” to learn more! Your likes and shares are greatly appreciated!

Your likes and shares are greatly appreciated!