Integrated circuits in aerospace applications are affected by the space radiation environment, facing the risk of failure. One of the main faults occurs when a single high-energy particle passes through sensitive nodes in the chip, generating ionized charge, leading to data flips, functional failures, current surges, or even destruction of the chip. The fault injection technology for integrated circuits involves establishing fault models to artificially inject faults into the chip, thereby accelerating the testing and evaluation of the chip and its circuit system’s fault processes. Laser fault injection technology is a highly efficient physical fault injection method due to its high spatial and temporal resolution, ease of energy adjustment, and flexibility of use, and it has received extensive attention in the field of single particle effect testing. Furthermore, in the new information security domain, integrated circuits face risks of human attacks. As a general fault generation technology, laser fault injection plays an important role in the reliability and security testing of integrated circuits.

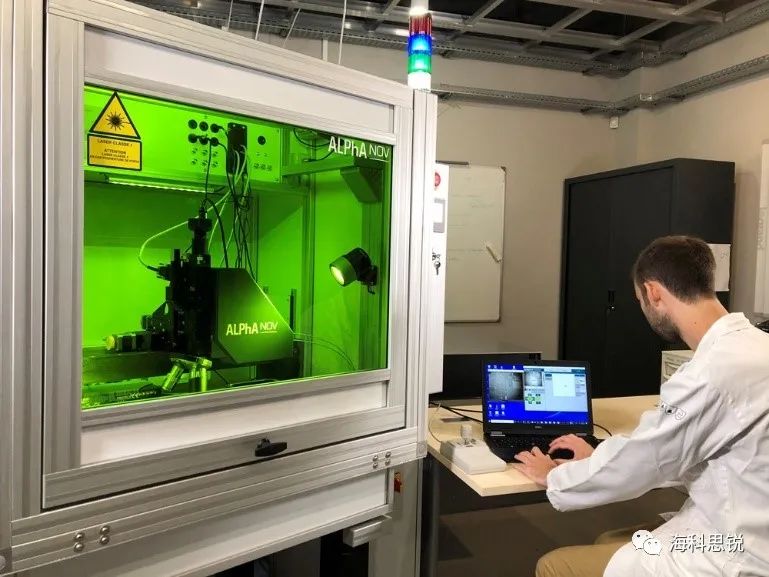

For over a decade, ALPhANOV in France has been developing optical and laser solutions for testing integrated circuits. Here, you can discover top high-precision equipment for laser fault injection, integrated circuit photon emission analysis, or laser thermal stimulation to read transistor states.

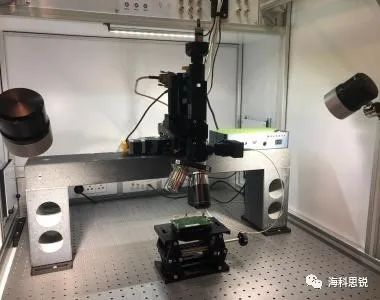

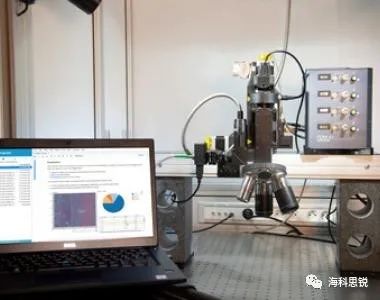

The S-LMS microsystem for laser fault injection is a high-precision platform for integrated circuit security assessment. It allows focusing the laser spot on the chip and evaluates the security level of electronic components by back-scanning the sample.

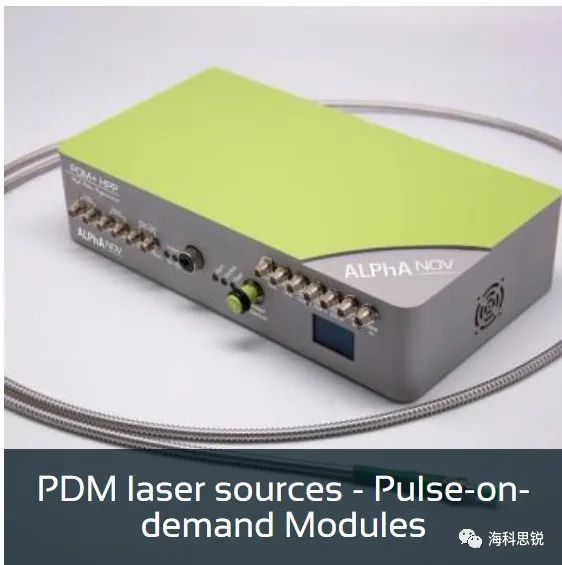

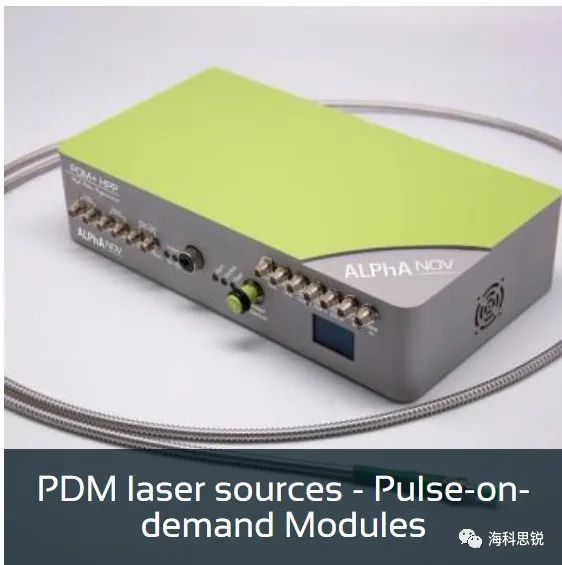

The S-LMS laser fault injection platform integrates optical components carefully designed by our team, focusing the laser source on the smallest possible spot size (1µm) with the highest possible transmittance (>90%). All power from the PDM+ laser source (Pulsed Demand Module) can be achieved on a very small circular spot and can be focused on the active area of the component from the back. This microscope system is mounted on a high-resolution XYZ stage capable of scanning samples at 50 nm.

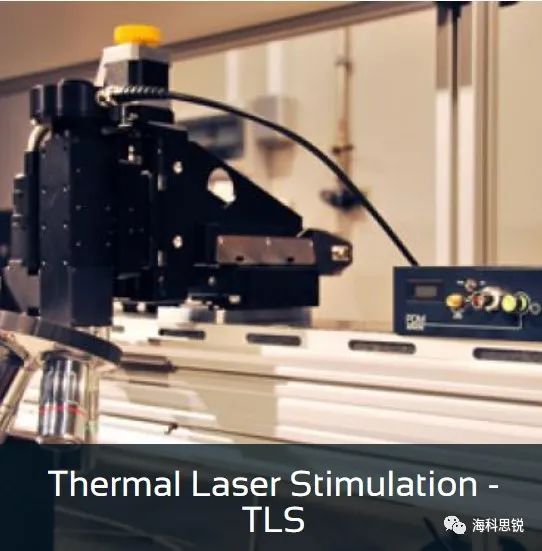

Time Precision of the Laser

Due to extremely low jitter (<8 ps), the PDM+ laser integrated into the fault injection microscope system allows for extremely precise timing control. This timing control is crucial for synchronizing laser injection with circuit operation. This PDM laser can generate on-demand pulses from 1ns to continuous wave; from single pulse to 250 MHz repetition frequency.

Different PDM+ models can be integrated into the S-LMS platform:

◆ Different wavelengths available: 980 nm and/or 1064 nm,

◆ Different power levels (from 2 W to 10 W) depending on sample sensitivity and silicon thickness,

◆ New PDM HPP (High Pulsed Performance) suitable for ultra-short pulses (sub-ns).

High-Quality Infrared Vision Module

The laser fault injection S-LMS microscope is specially designed to integrate high-quality infrared illumination and vision. The high-resolution infrared camera can obtain high-quality views of the chip through the back path, even through hundreds of microns of silicon. It also allows simultaneous observation of the laser spot, making it easy to place or move the laser spot on the sample.

ALPhANOV provides a range of high-performance lenses by focusing optical quality and high numerical aperture for better resolution and high transmission rate. The S-LMS workstation can integrate up to 4 lenses via a manual turret or 5 lenses via an electric turret. You can choose the most suitable magnification, from a 50x lens providing the smallest spot size to a 2.5x lens for a global view of the sample, or a larger spot size for faster scanning.

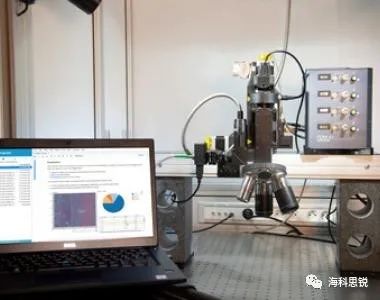

All our laser fault injection systems can now be controlled through esDynamic software from eshard. A powerful platform that can be used with laptops, leveraging Python tools, integrating your own development, and summarizing and analyzing your results. The esDynamic platform is also used for side-channel analysis.

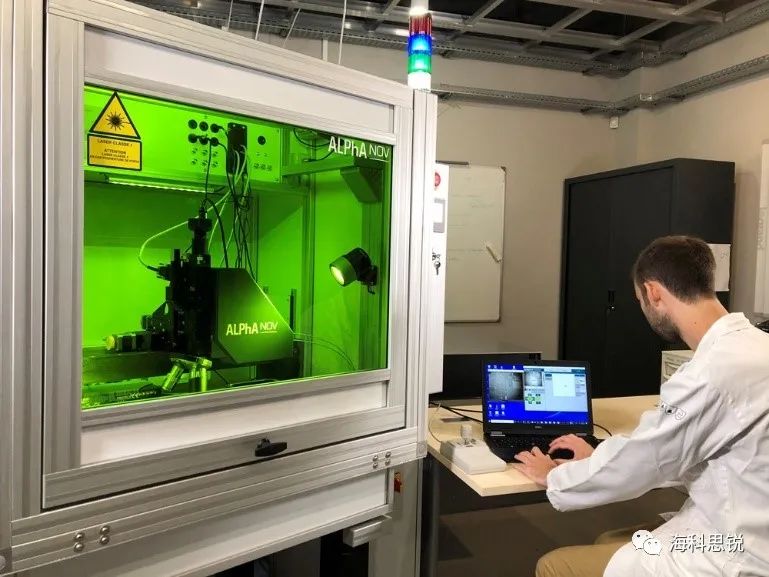

Turnkey and Continuously Updated Laser Fault Injection Systems

ALPhANOV, as an expert in the optical and laser field, can customize laser fault injection systems according to your project, budget, and skills. From custom test benches to turnkey test benches, we design the best solutions for you, from simple microscopes to fully automated machines with CE-certified laser safety enclosures, installed on actively isolated optical tables.

ALPhANOV develops and improves its laser fault injection platforms every year. You can regularly update/upgrade your system with the latest technological advancements to remain at the cutting edge. For example, photoluminescence or thermal laser simulation features are now available on the S-LMS workstation.

Additionally, ALPHANOV has developed a Dual Laser Fault Injection SystemD-LMS

The D-LMS microsystem for dual laser fault injection is a platform that allows for separate focusing and scanning of two laser points for integrated circuit security assessment. It is the ideal choice for dual-point injection processes, offering all spatial and temporal flexibility for circuit analysis from the back.The dual laser fault injection platform integrates two independent PDM+ laser sources (Pulsed Demand Module) focused through the same lens. The size of each laser spot ranges from 1µm to several tens of microns and can be moved independently across the entire field of view of the lens.

Beijing Haikesir Optoelectronic Instrument Co., Ltd. is the official authorized agent of ALPhANOV in China, fully responsible for the marketing, sales, and after-sales service of its products.

Beijing Haikesir, as a professional agent for laser/optoelectronic products, represents products including:Various lasers (semiconductor lasers, solid-state lasers, fiber lasers, gas lasers, etc., cw, nanosecond, sub-nanosecond, picosecond, femtosecond, single-frequency, broad-tuning, etc.), laser testing equipment (laser power/energy meters, beam analyzers, M2 instruments, spectrometers, wavelength meters, infrared viewers, photodetectors, autocorrelators, spiders, etc.), laser and optical components (laser optics, isolators, gratings, filters, semiconductor laser power supplies, fiber components), spectroscopic instruments, optical mechanics (optical isolation platforms, displacement tables, adjustment frames, optical machine components, etc.).