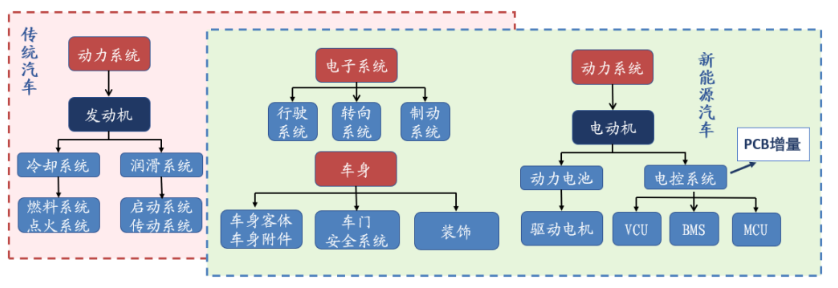

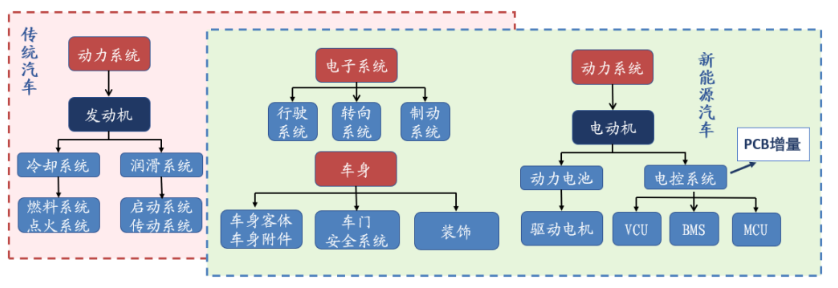

Hey friends, today let’s talk about a topic that is both high-tech and close to our lives—PCBs (Printed Circuit Boards) in new energy vehicles. Sounds a bit fancy and mysterious, right? Don’t worry, we will slowly unveil its veil and see how this “unsung hero” has become the electronic heart driving the future of new energy vehicles.

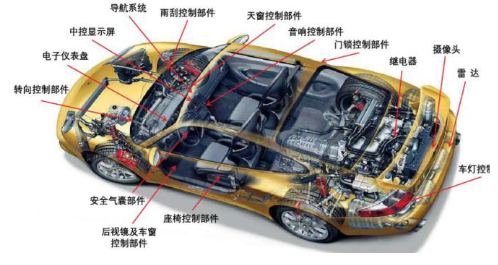

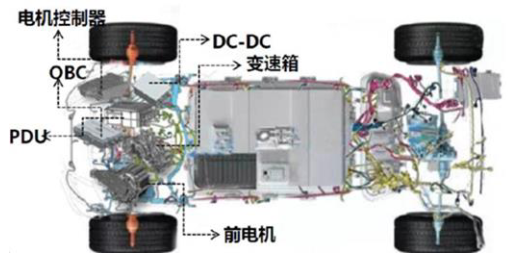

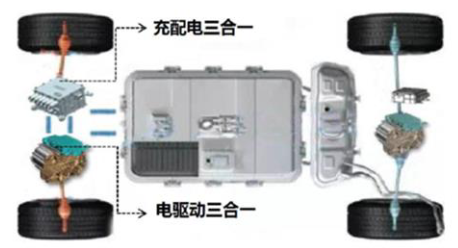

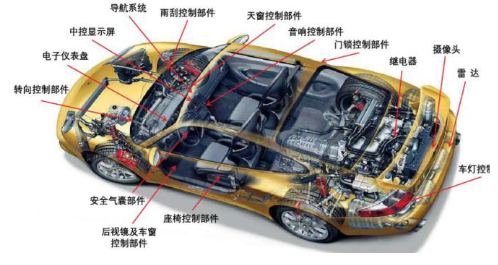

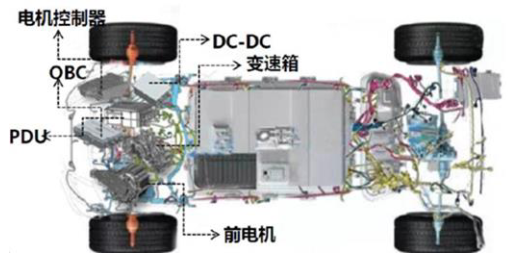

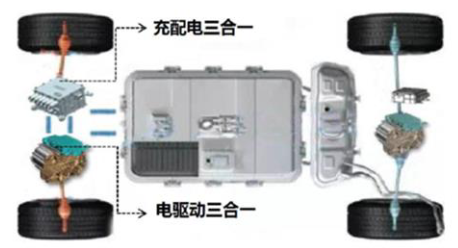

In the world of new energy vehicles, the application of PCBs is ubiquitous. From power control systems to safety control systems, to body electronic systems and communication systems, PCBs are everywhere. For example, the Battery Management System (BMS) requires PCBs to monitor the battery’s status, ensuring the battery operates safely and efficiently; the motor controller relies on PCBs to precisely control the motor’s speed and torque, allowing the car to run fast and steady. The braking system and Advanced Driver Assistance Systems (ADAS) in the safety control system also require PCBs for quick response and data processing, ensuring driving safety. The in-vehicle infotainment system and lighting system in the body electronic system, as well as the Vehicle-to-Everything (V2X) technology and onboard diagnostic systems in the communication system, all rely on the support of PCBs.

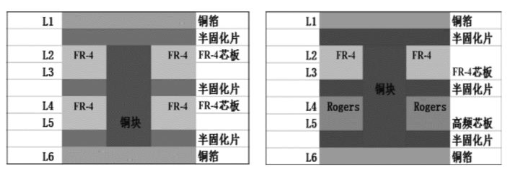

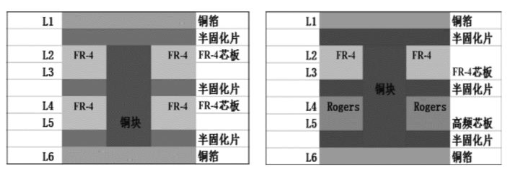

These PCBs are not ordinary PCBs; they need to meet the special requirements of new energy vehicles. Firstly, efforts must be made in materials and processes. The working environment of new energy vehicles is complex and variable, and PCBs must withstand high temperatures, humidity, and vibrations, which requires the use of higher-grade materials and special processing techniques. For instance, high-temperature resistant materials can ensure that PCBs operate stably in high-temperature environments near engines, while special processing techniques can enhance the fire resistance and corrosion resistance of PCBs.

Speaking of environmental adaptability, the PCBs in new energy vehicles must be able to cope with extreme temperature changes. Whether in a hot desert or a cold Arctic, PCBs must maintain performance without being affected. This requires consideration of these factors in the design of PCBs, such as using temperature-resistant materials and designing reasonable heat dissipation structures.

Reliability and durability are also important indicators of PCBs in new energy vehicles. The lifespan of cars is usually long, which means that PCBs must also withstand the test of time. This requires considering aging issues during long-term use in PCB design, as well as how to reduce failure rates. For example, optimizing circuit design and using high-quality materials can improve the reliability and durability of PCBs.

Safety standards are also an indispensable part of PCB design in new energy vehicles. For instance, international safety standards such as IPC standards and IATF16949 impose strict requirements on the design and manufacturing of PCBs. These standards cover various aspects such as material selection, circuit design, and manufacturing processes, ensuring the safety and reliability of PCBs. Additionally, environmental protection and lead-free compliance are also issues that need to be considered in the manufacturing of PCBs for new energy vehicles. With the increasing awareness of environmental protection, the production process of PCBs for new energy vehicles must also comply with environmental regulations such as RoHS, reducing the use of harmful substances.

When designing PCBs for new energy vehicles, the complexity of circuit design is a challenge. As automotive electronic systems become increasingly complex, the number of components on PCBs is increasing, which requires more meticulous circuit design to ensure signal integrity and power stability. At the same time, Electromagnetic Compatibility (EMC) and Electromagnetic Interference (EMI) are also issues that need to be considered in the design. With the increasing number of electronic devices in vehicles, they generate electromagnetic interference during operation, which requires consideration of how to reduce such interference in PCB design to ensure stable system operation.

Thermal management is also an important issue in the design of PCBs for new energy vehicles. As the power of electronic devices increases, heat dissipation issues become increasingly important. Poor heat dissipation can lead to overheating of the PCB, affecting its performance and lifespan. Therefore, PCB design must consider heat dissipation issues, such as designing reasonable heat dissipation structures and using heat dissipation materials.

Speaking of market prospects, the market for PCBs in new energy vehicles is rapidly growing. With the increase in sales of new energy vehicles, the demand for PCBs is also continuously rising. At the same time, technological innovation is constantly driving the development of the PCB industry. The development of new materials and manufacturing technologies continuously improves the performance of PCBs while reducing costs. This not only drives the development of the PCB market for new energy vehicles but also brings more opportunities to the entire new energy vehicle industry.

Globally, the competitive landscape of PCBs in new energy vehicles is also constantly changing. As technology matures and the market expands, more and more companies are entering this field. These companies gradually occupy a place in the global market through continuous technological innovation and market expansion. For example, some well-known PCB manufacturers have won customer trust and market recognition by providing high-quality products and services.

PCBs in new energy vehicles are not just simple circuit boards; they are the bridge connecting various parts of new energy vehicles and are key to ensuring the safe and efficient operation of new energy vehicles. With the rapid development of the new energy vehicle industry, the role of PCBs is becoming increasingly important. They not only drive the technological advancement of new energy vehicles but also bring more innovation and opportunities to the entire automotive industry. In the future, as technology continues to advance and the market continues to expand, PCBs for new energy vehicles will play an even more important role, becoming the electronic heart driving the future.