From casting molds to medical devices and artistic creations, 3D printing technology is increasingly applied across various fields such as industrial manufacturing, biomedical, and aerospace due to its rapid customization advantages. However, as 3D printing becomes a mainstream manufacturing technology, it is expected to generate more waste, which will become a global concern similar to other plastics.

In response to this challenge,Professor Xie Tao and Researcher Zheng Ning from the School of Chemical Engineering and Bioengineering at Zhejiang University have discovered a novel thermoreversible photochemical reaction, leading to the development of photopolymer 3D printing resins that can be recycled multiple times while exhibiting excellent mechanical properties. The related research was published in ‘Science’ on April 11, Beijing time, under the title ‘Circular 3D printing of high-performance photopolymers through dissociative network design’. The first author of the paper is Yang Bo, a PhD student at Zhejiang University, with Xie Tao and Zheng Ning as the corresponding authors, and Zhejiang University as the sole corresponding institution.

A Small Accident in the Experiment

Unlike traditional industrial manufacturing, which removes excess material through cutting to shape the workpiece, photopolymer 3D printing technology builds up layers based on a three-dimensional digital model. Under digital light exposure, liquid materials solidify layer by layer, akin to building with Lego blocks, adding material to construct a three-dimensional structure.

Despite decades of rapid development, 3D printing technology still faces numerous technical bottlenecks. Issues such as low manufacturing efficiency, insufficient mechanical properties of materials, and high resin costs hinder the widespread application of this technology.

Professor Xie’s team has long been dedicated to innovative research in 3D printing technology, achieving significant progress in improving manufacturing efficiency and developing high-performance resins.Last year, the team reported a 3D printing material with ultra-high mechanical properties in ‘Nature’, capable of stretching over nine times its original length. Building on their research in related fields, the team has been contemplating how to effectively reduce resin costs.

“If we can make ‘disposable’ 3D printing materials recyclable ‘infinitely’, it would not only help significantly reduce resin costs but also effectively minimize resource waste and environmental pollution, achieving both economic and environmental benefits,” Xie Tao explained.

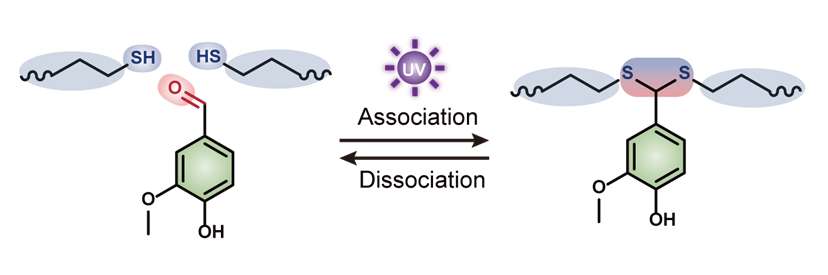

The Reversible Photochemical Reaction of Thiols and Aromatic Aldehydes

The raw materials for 3D printing consist of liquid monomers of photosensitive resins,“An unexpected addition of thiol reagents during the experiment led to results completely contrary to expectations,” Yang Bo recalled. Through in-depth analysis of the experimental phenomena, the team identified the key factor causing the ‘abnormal’ polymerization of the material—the photochemical reaction between aldehyde and thiol groups. “The condensation reaction of thiols and aromatic aldehydes is a classic chemical reaction,” Zheng Ning explained, noting that such reactions typically require prolonged heating to complete. “This small accident in the experiment allowed the team to confirm for the first time that this reaction can proceed quickly and efficiently under light induction, opening the door to the manufacture of high-performance, recyclable 3D printing materials.”

Rebuild Like Playing with Building Blocks

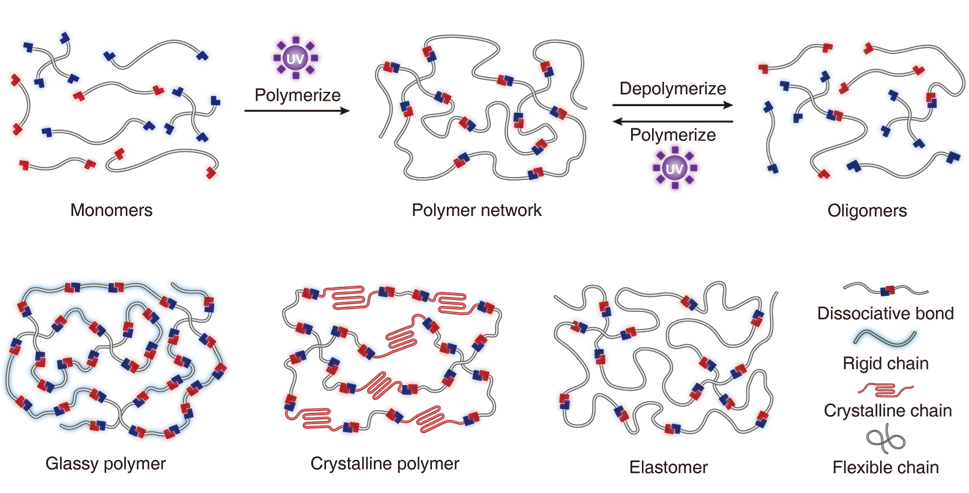

Recyclable plastics are an important direction for future sustainable development, but their chemical design for recyclability faces many challenges when applied to 3D printing. Existing photopolymer 3D printing typically relies on free radical chain polymerization of acrylate monomers, resulting in polymer networks with carbon-carbon single bonds in the main chain, making depolymerization and recycling difficult.

In contrast to traditional chain polymerization mechanisms, the team discovered that the disulfide bond generated from the condensation of thiols and aromatic aldehydes exhibits unique reversibility under thermal stimulation. Just like Lego blocks can be repeatedly assembled and disassembled, the disulfide bonds act like ‘snap-fit’ connections between two blocks. During photopolymerization, these ‘molecular blocks’ connect through the bonding of disulfide bonds to construct complex three-dimensional structures. Under appropriate heating, these bonds can be ‘unlocked’, allowing the resulting product to revert to the original state of thiols and aromatic aldehydes.

“This reversible mechanism means that used 3D printing materials can be recovered at the molecular level without damage through mild heating,” Xie Tao said, adding that the recycled raw materials can be reintroduced into the next round of 3D printing processes.This characteristic endows the materials with the ability to be reconstructed almost infinitely while significantly reducing raw material costs.

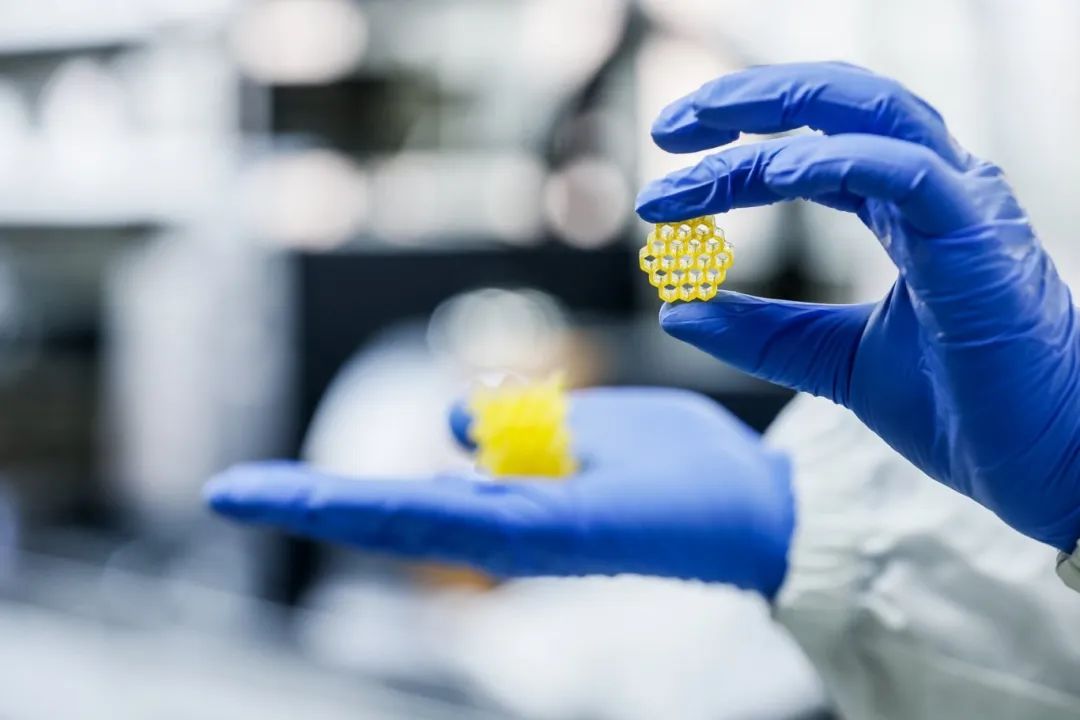

Based on this discovery, the team innovatively proposed a stepwise polymerization 3D printing system based on aldehyde/thiol reactions, achieving the construction of dynamic networks and thus pioneering a new strategy for 3D printing.“We have built a ‘Lego’ of polymer networks using this type of photochemical-thermal reversible dynamic chemistry, achieving recyclable 3D printing,” Xie Tao introduced.

Exhibiting Excellent Mechanical Properties

How can 3D printing materials possess a wide range of adjustable mechanical properties under recyclable conditions to meet different end-use applications?

Modular Polymer Network Design

Thanks to the advantages of the stepwise condensation mechanism, the above system allows for modular control of the main chain structure without affecting its recycling characteristics. “By molecular design to regulate the structure of the polymer main chain, we successfully prepared various 3D printing materials such as elastomers, crystalline polymers, and rigid polymers,” Zheng Ning explained,These polymers have broad application potential in lost foam casting (such as metal engines) and orthodontic brace production, and the same resin material can be reused to manufacture multiple components, reducing environmental pollution and resource waste.

“Our research has successfully broken through the inherent contradiction between the mechanical properties of traditional photopolymer 3D printing materials and closed-loop recycling at the molecular level. The constructed light-responsive dynamic disulfide chemistry system provides innovative molecular design for achieving high-performance photopolymer 3D printing materials’ closed-loop regeneration,which has significant guiding implications for the development of sustainable advanced manufacturing technologies.” Xie Tao said.

Text reporter: Cha Meng

Image reporter: Zhe Ying

Some images provided by the research team

Today’s editor: Student reporter team of the Zhejiang University Media Center Wu Wenbo | Zhang Shufan

Editor: Zhang Shufan Zhou Yiying

Exciting Recommendations Exclusive access to the campus is now open! Honoring the trust of life

Exclusive access to the campus is now open! Honoring the trust of life Check in at Zhejiang University, limited spots available!

Check in at Zhejiang University, limited spots available! Zhejiang University’s ‘Molecular Capturer’ Featured in ‘Nature’

Zhejiang University’s ‘Molecular Capturer’ Featured in ‘Nature’

Share this

Share this Save this

Save this View this

View this Like this

Like this