Team Paper Recommendation——Uncertainty Study on the Impact of Leading Edge Fouling on Aerodynamic Performance of Compressor Cascades

01

Article Information

Aerospace Science and Technology publishes articles related to aerospace research, fundamental studies, and applied technologies.

1. Aerospace Science and Technology is a leading international journal dedicated to advancing research in aerospace engineering and related interdisciplinary fields. The journal serves as a platform for cutting-edge theoretical, experimental, and applied studies.

2. The journal covers a broad spectrum of topics, including aerodynamics, propulsion systems, flight dynamics, structural mechanics, materials science, avionics, and space exploration technologies. It emphasizes innovation in design, computational modeling, and sustainable aerospace solutions.

Authors: Panpan Tu (涂盼盼), Guang Yang (杨光), Limin Gao (高丽敏), Tantao Liu (刘锬韬), Song Yang (杨淞)

Keywords: Leading edge fouling; Fouling modeling; Uncertainty quantification; Compressor blades

Citation Format: Panpan Tu, Guang Yang, Limin Gao, Tantao Liu, Song Yang, Uncertainty effect of leading edge fouling on aerodynamic performance of compressor cascades, Aerospace Science and Technology, 162(2025): 110235.

Article Download Link: https://doi.org/10.1016/j.ast.2025.110235

02

Research Background: The Threat of Fouling in Aerospace Power Systems

As one of the core components of an aircraft engine, the aerodynamic performance of the compressor directly affects engine efficiency and safety. However, during frequent takeoffs and landings, as well as low-altitude flights, suspended particles in the atmosphere (such as volcanic ash, salt mist, oil mist, etc.) continuously adhere to the blade surfaces, forming difficult-to-remove leading edge fouling. Research indicates that 70% to 80% of the aerodynamic performance degradation in engines is caused by fouling, leading to millions of dollars in fuel losses each year. More critically, the composition of fouling is complex (a mixture of particles ranging from 0.001μm to 2000μm) and its morphology is random (loose layers with complex and diverse rough structures), making it challenging to quantify its impact on performance uncertainty using traditional deterministic analysis methods, thus becoming an “invisible killer” threatening aviation safety.

03

Research Breakthrough: Transition from Deterministic to Uncertainty Studies

The research team published a paper in Aerospace Science and Technology, proposing for the first time a fouling uncertainty quantification model. The specific work includes:

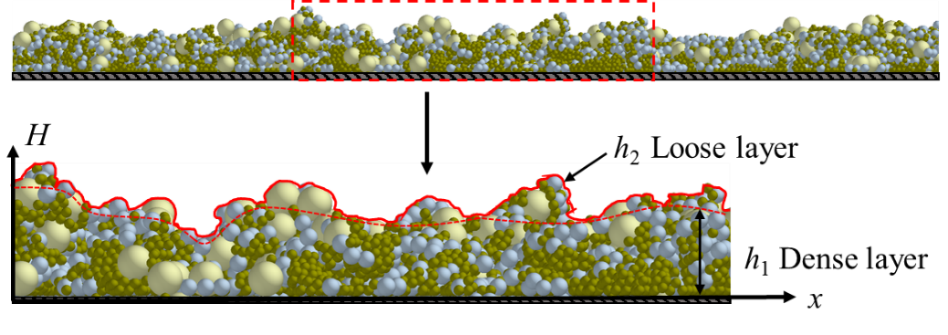

1. Layered Modeling: Decomposing fouling into dense layer thickness (macroscopic) and loose layer roughness (microscopic), using KL expansion and an improved Longuet-Higgins wave model to quantitatively characterize the geometric morphology of fouling.

2. Efficient Computation: Employing the Sparse Grid Non-Intrusive Polynomial Chaos (SGNIPC) method, reducing the computational load from the exponential growth of traditional Monte Carlo methods to linear scale, achieving high-precision uncertainty analysis with lower computational effort.

3. Risk Prediction: Through 10⁴ Monte Carlo samples, combined with the established fouling compressor SGNIPC method, quantifying for the first time the probabilistic risk of performance degradation caused by leading edge fouling.

Figure 1 Illustration of fouling morphology characteristics

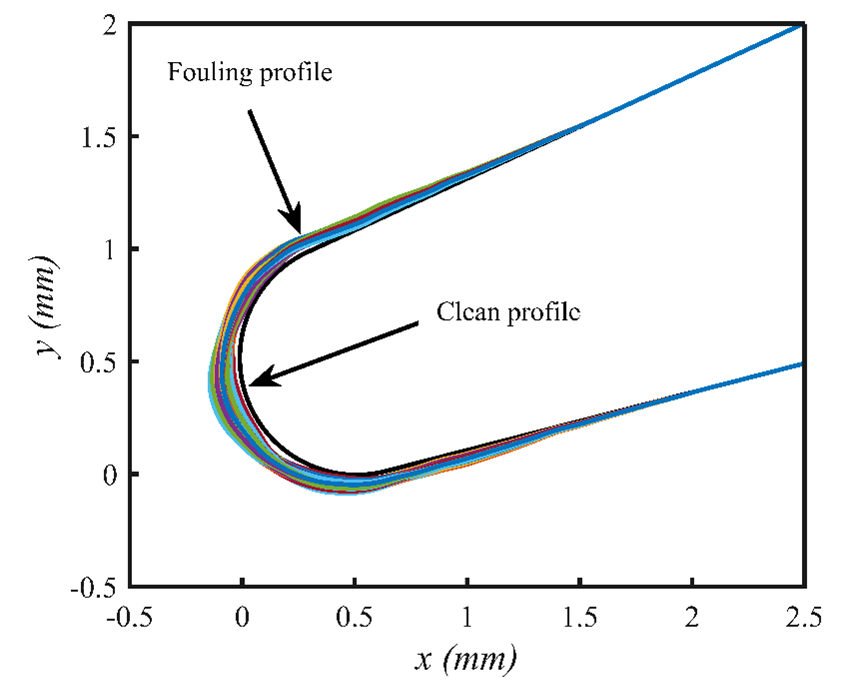

Figure 2 Geometric uncertainty modeling results of leading edge fouling

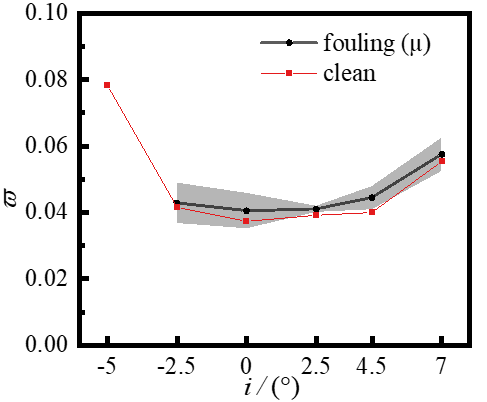

Figure 3 Angle of attack characteristics of leading edge fouled blades and clean blades at Ma = 0.5

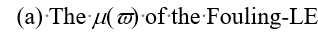

Figure 4 Probability density distribution of flow turning angle for leading edge fouled blades at Ma = 0.5

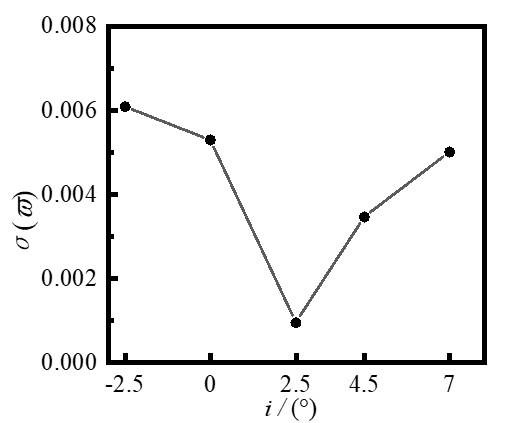

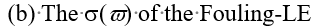

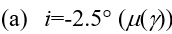

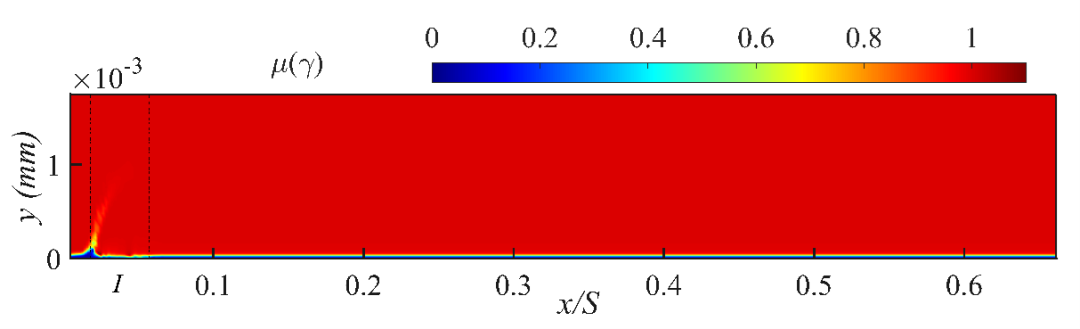

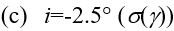

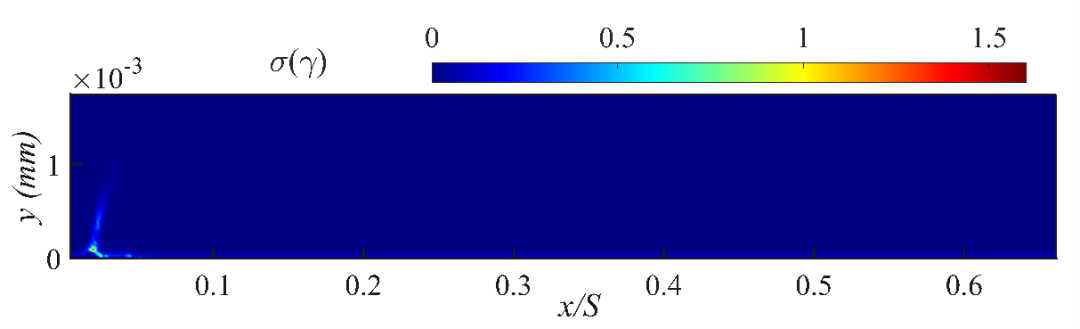

Figure 5 Mean and dispersion of intermittent factors on the suction side under leading edge fouling at Ma = 0.5

04

Core Findings: How Does Fouling Affect Flow Field Stability?

Through high-precision CFD simulations and flow mechanism analysis, the study reveals the “domino effect” of fouling:

1. Leading Edge Disturbance Propagation: Fouling alters the aerodynamic load distribution at the blade leading edge and transmits downstream, leading to increased uncertainty in the boundary layer transition point on the suction side, with significant dispersion in the transition region, greatly increasing flow losses.

2. Blurring of Stability Boundaries: The uncertainty of fouling transforms the stable operating range from a “clear threshold” to a probability distribution, resulting in a high performance dispersion even under design conditions, with the total pressure loss exceeding the μ+θ range with a probability of up to 14.28%.

05

Looking Ahead

The team is expanding the method to rotors and multi-stage compressors, transitioning from “experience-based maintenance” to “probabilistic safeguarding,” creating an “immune system” to address uncertainties for aircraft engines, pushing the maintenance and operation of aircraft engines from “remedial after the fact” to “preventive defense.” In a complex world interwoven with randomness and determinism, we illuminate every aircraft’s journey with the light of science.

Click below“Read the Original” to view the article

Editor | Xing Suwan

Reviewer | Mao Xiaocheng

Long press to recognize the QR code

Follow the High-Performance Compressor Design Team’s WeChat Official Account