As the application of industrial robots becomes increasingly widespread, programmable logic controllers (PLCs) are being extensively used to control industrial robots. For technicians engaged in the industrial robot industry or those looking to enter this field, mastering the knowledge and skills of communication between PLCs and industrial robots has become increasingly important. Thus, the “Illustrated Guide to Industrial Robot Control and PLC Communication” has emerged.

The “Illustrated Guide to Industrial Robot Control and PLC Communication” is suitable for engineering technicians engaged in the debugging and maintenance of industrial robots in enterprises, as well as students in colleges and universities studying industrial robot debugging and maintenance, mechatronics, electrical automation, and other related majors.

The “Illustrated Guide to Industrial Robot Control and PLC Communication” is suitable for engineering technicians engaged in the debugging and maintenance of industrial robots in enterprises, as well as students in colleges and universities studying industrial robot debugging and maintenance, mechatronics, electrical automation, and other related majors. This book is divided into six chapters, explaining the communication technology between ABB, FANUC, KUKA industrial robots and PLCs through illustrations.

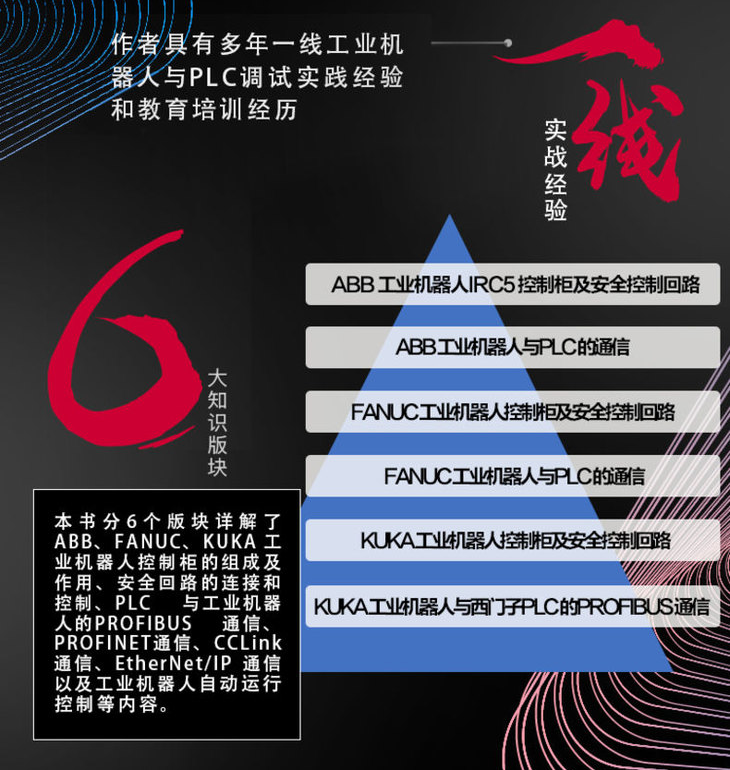

This book is divided into six chapters, explaining the communication technology between ABB, FANUC, KUKA industrial robots and PLCs through illustrations.

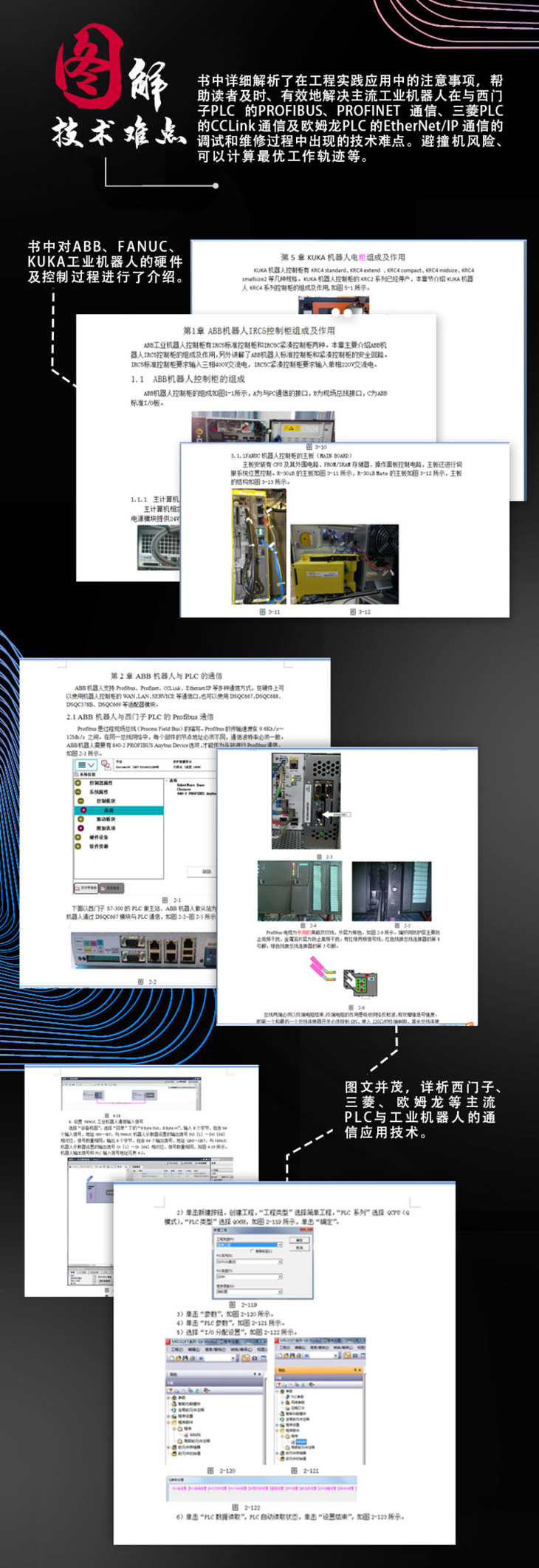

- Chapter 1 introduces the composition and function of the ABB industrial robot control cabinet, as well as the connection and control of safety control circuits.

- Chapter 2 discusses the communication between ABB industrial robots and Siemens PLCs using PROFIBUS, PROFINET, the communication between ABB industrial robots and Mitsubishi PLCs using CCLink, and the EtherNet/IP communication of ABB industrial robots.

- Chapter 3 introduces the composition and function of the FANUC industrial robot control cabinet, as well as the connection and control of safety control circuits.

- Chapter 4 covers the communication between FANUC industrial robots and Siemens PLCs using PROFIBUS, PROFINET, the communication between FANUC industrial robots and Mitsubishi PLCs using CCLink, the EtherNet/IP communication between FANUC industrial robots and Omron PLCs, and the automatic operation control of FANUC industrial robot programs.

- Chapter 5 introduces the composition and function of the KUKA industrial robot control cabinet, as well as the connection and control of safety control circuits.

- Chapter 6 discusses the communication between KUKA industrial robots and Siemens PLCs using PROFIBUS, PROFINET communication, and external automatic operation control of KUKA industrial robots.

Click the image to purchase

Drag the scroll bar on the right to view the full directory▼Directory

Preface

Chapter 1: ABB Industrial Robot IRC5 Control Cabinet and Safety Control Circuit …1

1.1 Composition and Function of ABB Industrial Robot IRC5 Control Cabinet …1

1.1.1 Main Computer Unit …1

1.1.2 Axis Computer Board …2

1.1.3 Drive Units for the Six Axes of the Robot …2

1.1.4 Teach Pendant and Control Cabinet Operation Panel …3

1.1.5 Serial Measurement Board …3

1.1.6 System Power Module …4

1.1.7 Power Distribution Board …4

1.1.8 Capacitor Unit …5

1.1.9 Contactor Board …5

1.1.10 Safety Board …5

1.1.11 Control Cabinet Transformer …6

1.1.12 Bleed Resistor …6

1.1.13 User Power Supply Module …6

1.1.14 I/O Unit Module …6

1.1.15 Overall Connection Diagram of the Control Cabinet …7

1.2 Safety Control Circuit of ABB Industrial Robot …8

1.2.1 Emergency Stop Control Circuit of Standard ABB Industrial Robot Control Cabinet …8

1.2.2 Automatic Stop, Normal Stop, and Upper-level Stop Control Circuits of Standard ABB Industrial Robot Control Cabinet …11

1.2.3 Emergency Stop Circuit of Compact ABB Industrial Robot Control Cabinet …13

1.2.4 Safety Circuit of Compact ABB Industrial Robot Control Cabinet …15

Chapter 2: Communication between ABB Industrial Robots and PLCs …17

2.1 Communication between ABB Industrial Robots and Siemens PLCs using PROFIBUS …17

2.1.1 Configuration of ABB Industrial Robot PROFIBUS …19

2.1.2 Creating I/O Signals for PROFIBUS …24

2.1.3 PLC Configuration …27

2.1.4 Associating System Inputs/Outputs with I/O Signals …34

2.1.5 PLC Programming …37

2.2 Communication between ABB Industrial Robots and Siemens PLCs using PROFINET …38

2.2.1 ABB Industrial Robot PROFINET Communication via DSQC688 Module …40

2.2.1.1 Configuration of PROFINET Communication via DSQC688 …40

2.2.1.2 Creating I/O Signals for PROFINET …44

2.2.1.3 PLC Configuration …46

2.2.1.4 Establishing PROFINET Communication between PLC and ABB Industrial Robot …53

2.2.2 ABB Industrial Robot PROFINET Communication via WAN and LAN3 Ports …54

2.2.2.1 Configuration of PROFINET Communication via WAN and LAN3 Ports …54

2.2.2.2 Creating I/O Signals for PROFINET …59

2.2.2.3 PLC Configuration …61

2.2.2.4 Setting Communication Input/Output Signals for ABB Industrial Robot …66

2.2.2.5 Establishing PROFINET Communication between PLC and ABB Industrial Robot …66

2.3 Communication between ABB Industrial Robots and Mitsubishi Q Series PLCs using CCLink …67

2.3.1 DSQC378B Module …67

2.3.2 Mitsubishi PLC Settings …68

2.3.3 PLC Programming …69

2.3.4 ABB Industrial Robot Settings …73

2.4 Configuration of ABB Industrial Robot EtherNet/IP Communication …80

2.4.1 Application of ABB Industrial Robot 841-1 EtherNet/IP Scanner/Adapter Option …80

2.4.2 Application of ABB Industrial Robot 840-1 EtherNet/IP Anybus Adapter Option …84

2.5 Socket Communication …88

2.5.1 Socket Communication Settings …88

2.5.2 Creating Socket Communication …90

2.5.3 Example of Socket Communication Application …92

Chapter 3: FANUC Industrial Robot Control Cabinet and Safety Control Circuit …94

3.1 Composition and Function of FANUC Industrial Robot Control Cabinet …94

3.1.1 Main Board of FANUC Industrial Robot Control Cabinet …97

3.1.2 Main Board Battery …98

3.1.3 FANUC Input/Output Printed Circuit Board …98

3.1.4 Power Supply Unit …99

3.1.5 Teach Pendant …100

3.1.6 Servo Amplifier …101

3.1.7 Operation Panel …102

3.1.8 Transformer …102

3.1.9 Fan Unit and Heat Exchanger …102

3.1.10 Circuit Breaker …102

3.1.11 Regenerative Resistor …102

3.2 Safety Control Circuit of FANUC Industrial Robot …103

3.3 Emergency Stop Unit …111

Chapter 4: Communication between FANUC Industrial Robots and PLCs

Chapter 5: FANUC Industrial Robot Control Cabinet and Safety Control Circuit

Chapter 6: Communication between KUKA Industrial Robots and PLCs

Source: Jinfen Mall