Free for commercial use! A low-code visual development platform for industrial web with over 1500 components.

Provocative question!!! Can a host computer replace a PLC?

Revealing the efficiency boost once DCS is online?

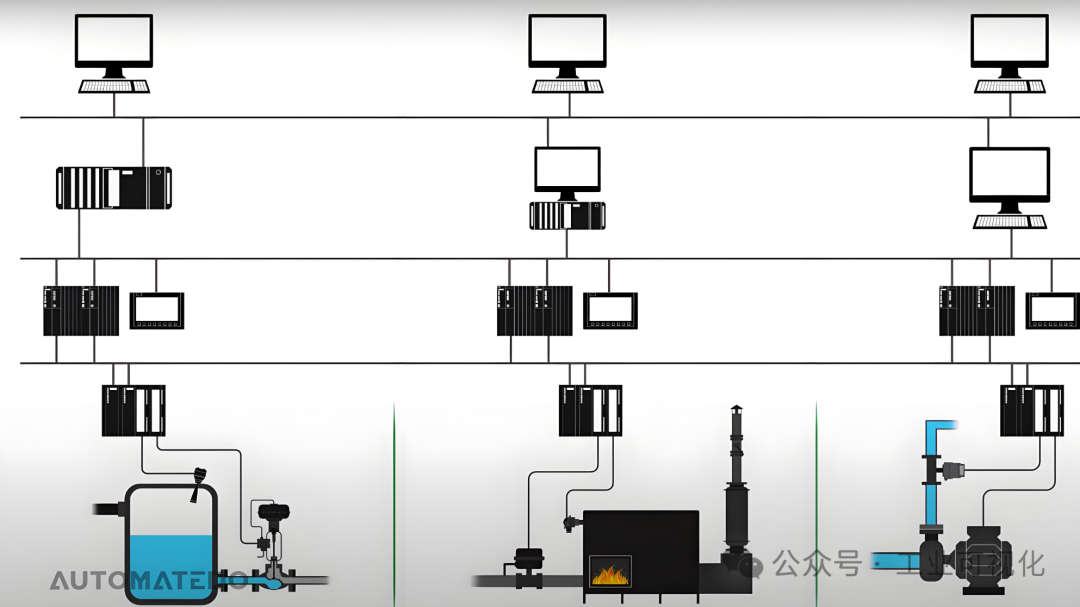

In modern industrial automation systems, PLC (Programmable Logic Controller) and DCS (Distributed Control System) are two common yet distinct control architectures. So, how do these two work together in the same system, and what roles do they each play? This article will analyze the collaboration mechanism of both from a technical perspective and explore it in depth with practical cases.

Different Roles, Each with Their Own Duties

First, we need to clarify the functional positioning of PLC and DCS—this lays the foundation for their collaborative work. PLC excels in logical control and high-speed sequential control, commonly used for device-level control, such as discrete logic, motion control, and machine scheduling. Due to its high reliability, fast response, and ease of configuration, it has become the core of workshop equipment automation.

On the other hand, DCS is used for more high-level process control and data management, suitable for handling multi-variable adjustments, distributed remote control, and global optimization. DCS typically plays the role of the “brain” in process industries such as petrochemicals and power generation, managing precise adjustments involving complex signals like temperature, pressure, and flow.

In short, PLC is more like an “executor,” responsible for device-level operations; DCS is the “commander,” responsible for system-level coordination.

Collaboration Mechanism: Integration from Hardware to Software

Interconnection at the Hardware Level

In collaborative work, PLC and DCS often connect through industrial communication protocols. Common protocols include Modbus, Profibus, Ethernet/IP. These protocols allow PLC to upload device status information (such as motor speed and valve switch status) to DCS, while DCS sends global scheduling commands (such as temperature setpoints) to PLC for execution.

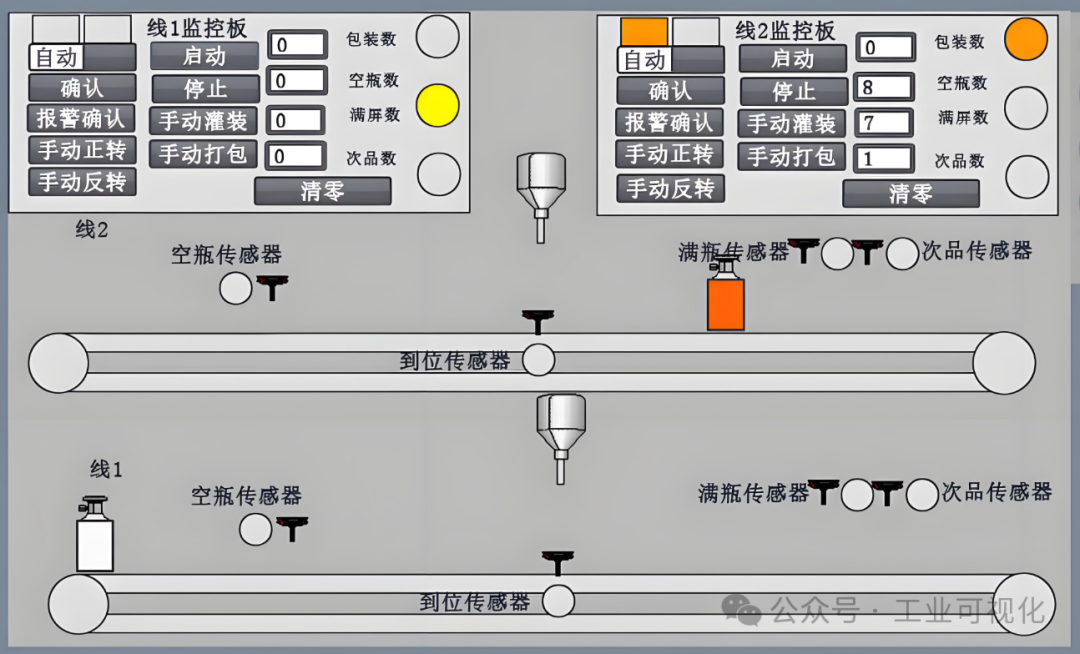

For example, in a brewery, PLC is responsible for monitoring and operating the filling machine, while DCS adjusts process parameters such as temperature and pressure on the production line. Through the Modbus protocol, DCS receives real-time status data from the filling machine and sends new parameter setting commands to PLC based on process requirements, achieving efficient integration.

Logical Coordination at the Software Level

In addition to hardware access, software logic coordination is also crucial. DCS sets global monitoring and optimization strategies, such as setting alarm thresholds and safety boundaries, while PLC is responsible for local safety and low-latency control. In the event of an anomaly, such as equipment exceeding limits, PLC will prioritize emergency stop control and report to DCS through the communication module, which will then assess and adjust the entire system.

Specifically, the logical collaboration between DCS and PLC is usually achieved through a hierarchical control model. The lower-level PLC is responsible for real-time execution (such as turning on a pump), while the higher-level DCS is responsible for scheduling optimization (such as determining when to start the pump and controlling flow).

Advantages of Collaborative Work

In the field of industrial control, the collaboration between PLC and DCS combines the advantages of both, ultimately achieving an effect of “1+1>2”:

- Efficiency: PLC is responsible for micro-control, rapidly responding to local events, while DCS optimizes from a global perspective to avoid resource waste.

- Redundancy and Safety: The hierarchical control between the two enhances fault management capabilities. For instance, a failure in a single PLC node does not affect the overall monitoring by DCS.

- Strong Scalability: The collaborative architecture is more easily integrated with IoT or MES systems, laying the foundation for modern smart manufacturing.

Practical Case Study: Applications in the Petrochemical Industry

In a petrochemical plant, PLC typically handles real-time control of field devices (such as valves, motors, and compressors), while DCS monitors the entire production process. In a certain refinery, DCS communicates with multiple PLCs via Ethernet to monitor the entire production line. From crude oil transportation to refining processes, DCS has full control, while PLC directly handles real-time execution tasks. This collaborative approach significantly improves the precision and stability of the entire process while achieving transparent management of production data.

Outlook: The Trend of Integration between PLC and DCS

With the in-depth development of Industry 4.0, the boundaries between PLC and DCS are gradually blurring. In modern industrial control architectures, DCS is beginning to integrate some high-performance PLC functions, while PLC is also evolving towards a “mini DCS” by supporting advanced programming languages and stronger network communication capabilities. For example, cloud control and edge computing are being introduced into a hybrid control model that combines both.

In summary, the collaborative work of PLC and DCS provides a smarter and more efficient platform for industrial automation. Through hardware interconnection, software coordination, and reasonable division of labor, the two achieve perfect synergy in numerous engineering applications. In the future, with technological advancements, we can expect further integration of the two, building a more advanced control network in smart factories.

Recent Popular Articles:

| Summary by Industrial Control Experts!!! Key to Implementing SCADA with OPC UADo you really know how to use Modbus TCP?Without this 120 ohms!!! Wait for the 485 avalancheProvocative question!!! Can a host computer replace a PLC?Want to understand industrial communication? First, get the Modbus frame structure right! |