Hidden Costs of Isolated RS-485 Optocoupler Design

Optocouplers, also known as optical isolators or optoelectronic couplers, have been used for over 40 years to achieve current isolation in electronic circuits. Optocouplers use LEDs and phototransistors to communicate signals without transmitting current. As a low-cost solution, optocouplers have remained popular. But considering the advancements in digital isolation technology, is an optocoupler really the most cost-effective way to achieve current isolation in RS-485 systems?

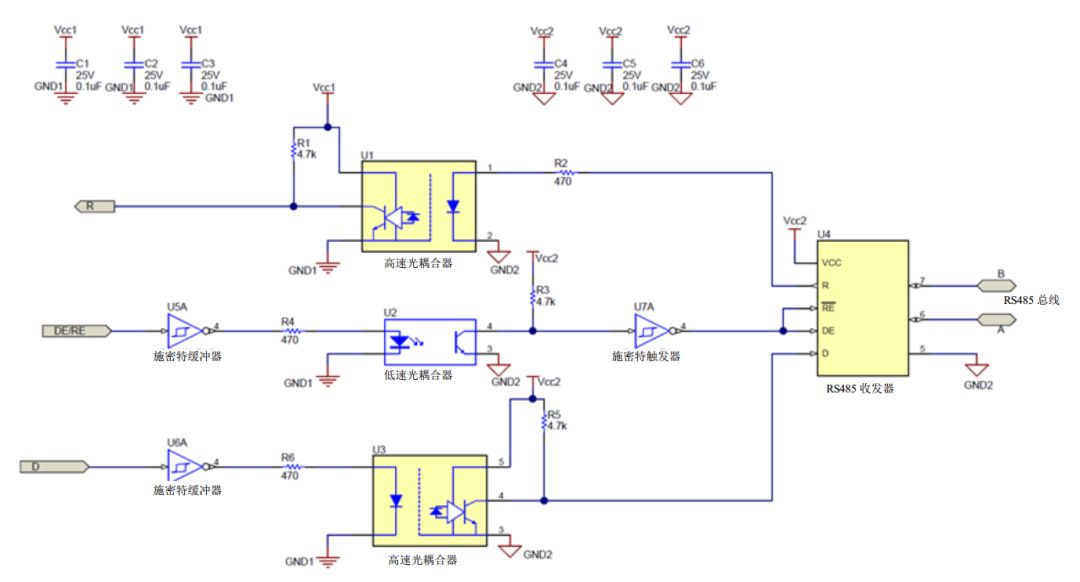

Figure 1: Isolated RS-485 Design Using Optocouplers

As shown in Figure 1, a typical circuit for an isolated RS-485 transceiver using optocouplers achieves current isolation. This solution requires three optocouplers: two high-speed optocouplers (one for sending and one for receiving signals) and one low-speed optocoupler for direction control. This solution also requires a significant number of external components, including Schmitt buffers, Schmitt triggers, resistors, and bypass capacitors. All these components add to the cost and circuit board area.

Today, many system designers face the issue of circuit board space limitations across various industrial markets as they aim to achieve smaller overall solution sizes or enhanced functionality with each new product generation. One example is HVAC systems that regulate temperature and airflow in buildings. With the trend toward smart energy-efficient buildings, new HVAC control boards need to integrate advanced monitoring and interfaces with smart thermostat systems without increasing the overall solution size.

RS-485 is a universal communication interface in these systems due to its long-distance reliability. When RS-485 nodes are placed in locations with different ground potentials, common-mode noise can cause communication failures, necessitating isolation to prevent these ground potential differences. Using bulky optocoupler solutions to isolate RS-485 forces designers to compromise in other areas of the system, creating a demand for smaller isolation interface solutions.

In addition to large-size solutions, many designers also encounter these performance issues with optocouplers:

-

Reliability: Optocouplers typically use epoxy as the dielectric; compared to other common dielectrics, epoxy can break down at lower voltages, as shown in Figure 2. Component inconsistencies and LED degradation can also lead to differences in isolation reliability and lifespan from device to device.

-

Power Consumption: Each optocoupler requires 5-10 mA to drive the LED on the internal input chip.

-

Temperature Range: Most optocouplers are limited to a maximum ambient temperature of 85°C, with very few exceptions capable of withstanding temperatures up to 105°C.

-

Switching Specifications: The rise/fall time and propagation delay of optocouplers vary with bias current, current transfer ratio, and device-to-device variations.

-

Noise Immunity: The typical common-mode transient immunity range for optocouplers is from 15 kV/μs to 25 kV/μs. In the case of voltage transients above this level, data corruption is likely to occur.

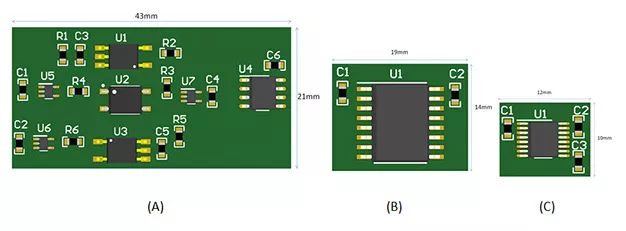

To meet the growing demand for compact solutions without compromising performance, Texas Instruments has developed the ISO1500 isolated RS-485 transceiver. Figure 3 compares the size of this solution with the optocoupler solution shown in Figure 1, which is the industry-standard 16-pin small outline integrated circuit (SOIC) isolated RS-485 transceiver and the ISO1500. Note that these designs only show signal isolation for the RS-485 transceivers.

Figure 3: Comparison of Solution Sizes Between Optocoupler Solutions (a);

Industry-standard 16-pin SOIC Isolated RS-485 Transceiver (b);

And Texas Instruments’ ISO1500 (c)

Compared to discrete optocoupler solutions, the ISO1500 can reduce circuit board space by up to 85%, and save up to 50% of circuit board space compared to the industry-standard 16-pin SOIC package. In addition to minimizing solution size, the ISO1500 also addresses many of the performance issues mentioned above. All Texas Instruments isolated RS-485 transceivers are manufactured using semiconductor fabrication processes, utilizing silicon dioxide as the dielectric to minimize differences between devices and provide more reliable high-voltage performance. The ISO1500 consumes <10μA of current to drive the complementary metal-oxide-semiconductor-based input, and can operate in a temperature range of -40°C to 125°C. Compared to traditional optocouplers, it features predictable switching specifications and higher noise immunity. When these system-level advantages are combined with the circuit board space savings achieved by using the ISO1500, it is clear that the costs of optocouplers far exceed just the price paid for the devices.

Click “Read Original” to learn more about the ISO1500.

Just click me if you are watching~