Recently, Nike announced its latest achievement in 3D printing – the Nike FlyWeb fabric. According to official sources, Nike FlyWeb fabric is made from soft and elastic thermoplastic polyurethane (TPU) material, formed into an ideal product shape through 3D printing technology. The first product to use Nike FlyWeb fabric is a women’s sports bra.

On June 26, 2025, Kenya’s middle-distance running queen Faith Kipyegon wore a sports bra made from Nike FlyWeb fabric during the “Breaking4” challenge in Paris, aiming to become the first woman in history to run a mile in under 4 minutes. Although she ultimately missed the 4-minute mark, she completed it in 4 minutes and 6.42 seconds, which was 1.22 seconds faster than her own world record.

3D Printed TPU: From Footwear to Apparel

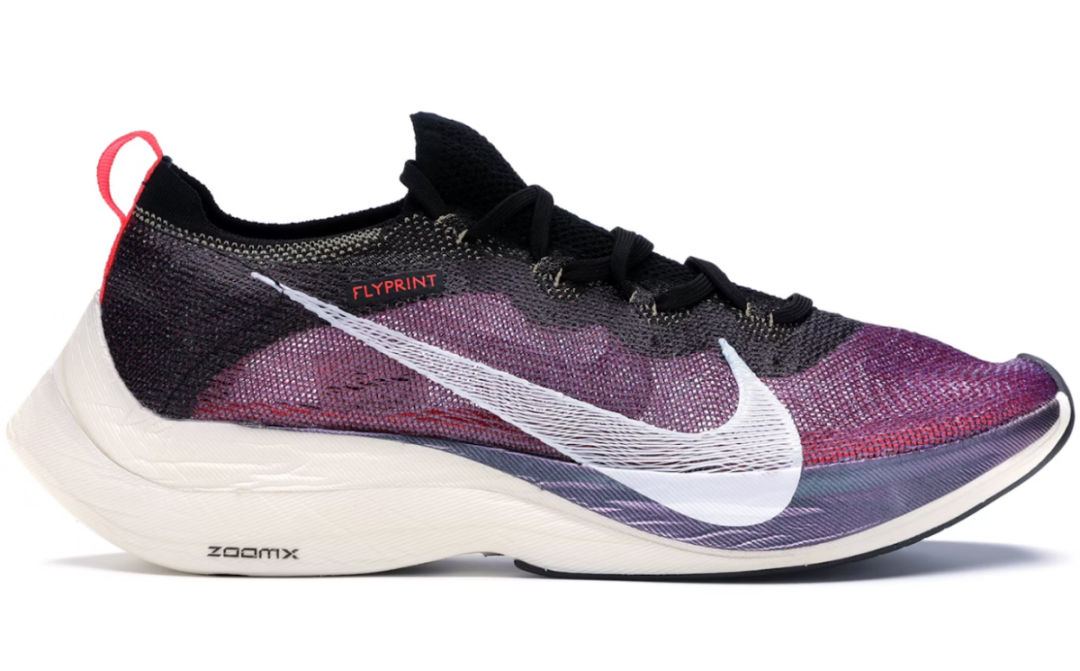

In recent years, sports brands have increasingly integrated 3D printing technology into their products, using thermoplastic polyurethane (TPU) as the material.However, for a long time, many mass-produced and event-customized products have focused on innovations in footwear, including soles and uppers.For example, Adidas’s Futurecraft 4D and 4DFWD shoes use 3D printed TPU material for the midsole’s grid structure; Nike’s Flyprint upper is made from 3D printed TPU; and Peak’s Future series combines 3D printed TPU midsoles and uppers…

However, the application of 3D printed TPU material in apparel is a first.

3D Printed TPU Sports Bra: Providing Ultimate Breathability

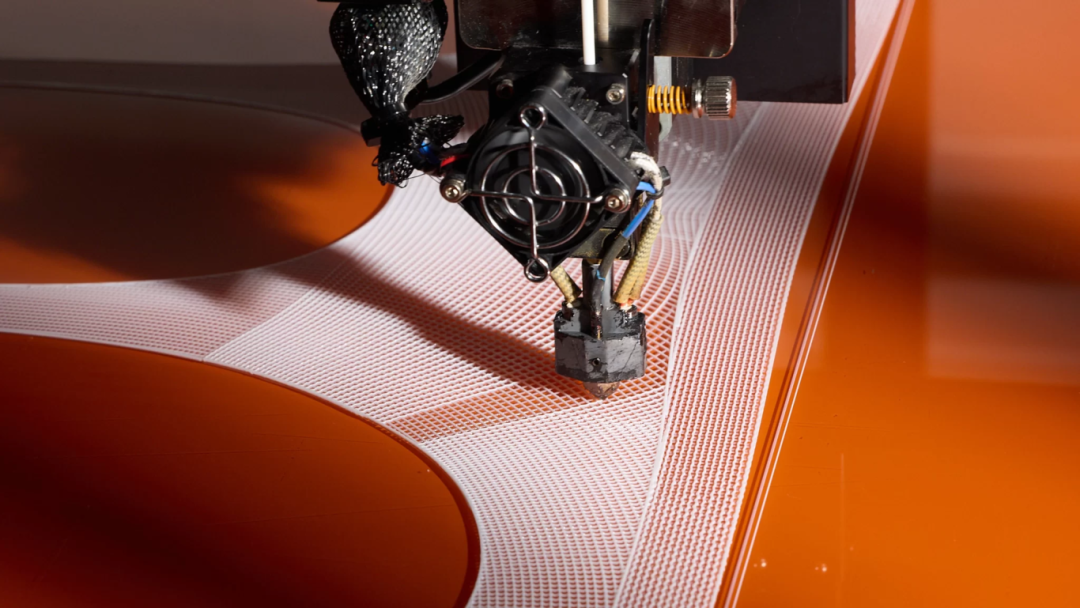

Nike FlyWeb fabric is made from thermoplastic polyurethane (TPU) and is manufactured using 3D printing technology rather than traditional knitting or weaving processes. This material is designed to form a seamless single-layer structure through computational design, allowing designers to adjust the density in different areas of the garment to modify parameters such as stretchability, breathability, and support.According to Nike innovator Janett Nichol, “We spent years redesigning – not just the material, but the entire design concept – to achieve the softness, breathability, and aesthetic appeal required for apparel with Nike FlyWeb fabric.”

This research focuses on sports bras, a category that has seen little change in material structure for decades. The 3D printed design eliminates the traditional multi-layer structure of sports bras, significantly enhancing breathability and moisture-wicking performance. Its support comes from structural design rather than traditional compression and padding, with denser patterns printed in areas that require support.According to Janett Nichol, testers unanimously reported that the wearing experience felt almost weightless: “This is the most important feedback we received from testers: it feels invisible on your body, yet provides incredible support.”

It is reported that the FlyWeb sports bra uses a TPU material optimized by Nike, with a 3D printing nozzle weaving TPU filaments with 0.1mm precision, creating a dynamic mesh for the body – reducing chest movement by 40% while running and increasing underarm breathability by 60% during jumps.

Tests show that athletes wearing the FlyWeb sports bra experience a 15% reduction in lactic acid buildup and a 22-minute extension in muscle fatigue time.

Nike FlyWeb fabric intelligently conforms to the body’s curves without relying on seams, straps, or excess material. Janett Nichol noted that some testers felt airflow across their chest while running for the first time, “Most women have never experienced this because we never dared to hope that a sports bra could provide such a sensation.”

Although Nike has previously applied 3D printing technology in footwear, Nike FlyWeb fabric marks the brand’s official entry into the high-performance apparel sector using 3D printing. This also reflects the industry’s exploration of additive manufacturing technology in the field of close-fitting wear. While no other FlyWeb product plans have been announced, Nike emphasizes that this project will continue to advance. Janett Nichol believes:“This is not only a breakthrough for sports bras but also opens up a new perspective for the future design of high-performance apparel.”

Source: Translated and published by Ratech Consulting.