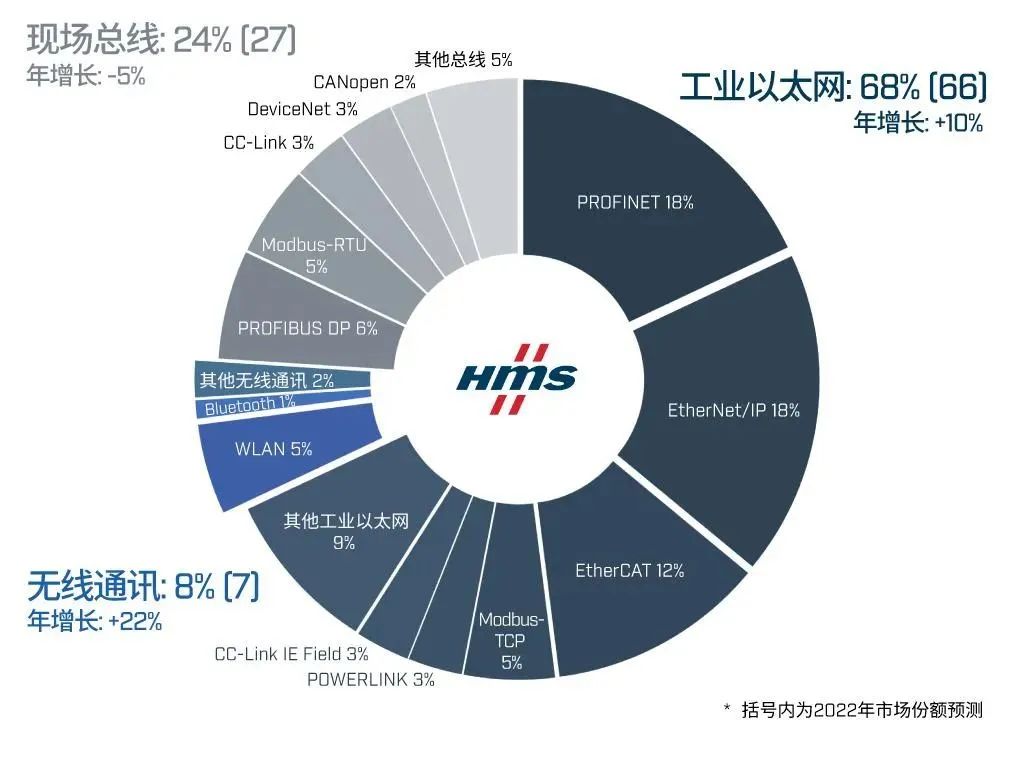

In today’s rapidly changing field of industrial automation, the choice and application of network protocols have become increasingly important. Among them, PROFINET and EtherNet/IP, as two major mainstream network protocols, occupy a significant position in the market with their unique advantages, each holding an 18% market share, tied for first place.

PROFINET, with its efficient, stable, and real-time data transmission capabilities, is favored by the manufacturing industries in Europe and the Middle East. Its standardized design allows devices from different manufacturers to connect seamlessly, providing great convenience for data exchange on industrial production lines. At the same time, PROFINET has also achieved remarkable success in the Asian market, particularly among large manufacturing enterprises, where its market share ranks among the top.

On the other hand, EtherNet/IP has gained popularity among users due to its openness and compatibility. As a combination of Ethernet and IP technology, EtherNet/IP not only inherits the high-speed and efficient characteristics of Ethernet but also enables remote communication and monitoring between devices through IP technology. In the Americas market, EtherNet/IP has successfully dominated due to its powerful functionalities and extensive application base.

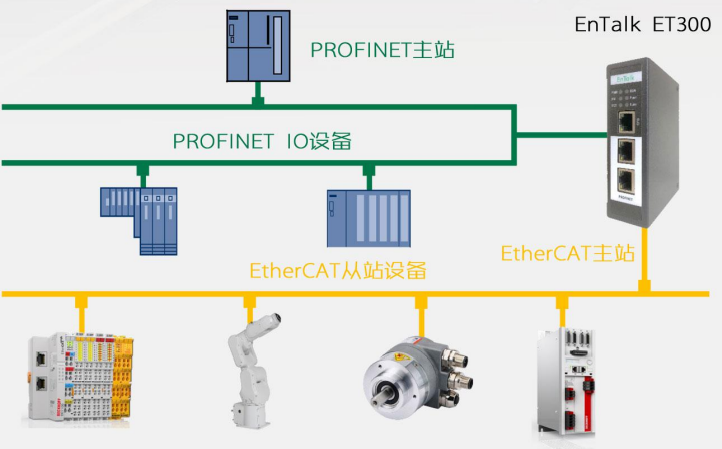

However, despite the equal footing of PROFINET and EtherNet/IP in the market, this does not mean that other network protocols do not have a place. EtherCAT has gradually emerged in the market due to its fast data transmission speed and strong synchronization performance. Particularly in applications requiring high-precision synchronized control, EtherCAT shows significant advantages. In the Americas market, EtherCAT is growing rapidly, with an expanding market share.

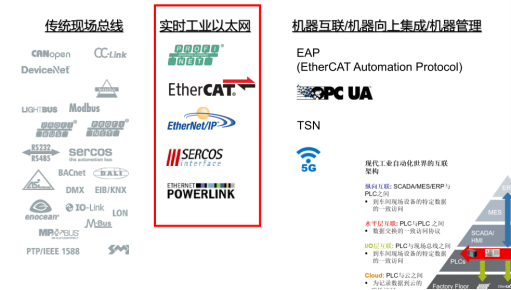

Furthermore, industrial Ethernet, as an important infrastructure in the field of industrial automation, has achieved an astonishing growth rate of 10%. Industrial Ethernet accounts for 68% of the new installation nodes in global factory automation, an increase from 66% last year. This growth trend indicates that industrial Ethernet is gradually replacing traditional fieldbus technologies, becoming the mainstream choice in the field of industrial automation.

In different regions, the application of network protocols also shows certain differences. In Europe and the Middle East, in addition to PROFINET and EtherNet/IP, PROFIBUS and Modbus-TCP are also important competitors. These protocols have their own characteristics and meet the diverse needs of different users. In the Asian market, due to vast geography and uneven economic development, the application of network protocols is relatively fragmented. In addition to PROFINET and EtherNet/IP, protocols such as CC-Link/CC-Link IE Field and EtherCAT also occupy a certain market share.

The industrial network protocol market is fiercely competitive, with various protocols each having their strengths. In the future, as industrial automation technology continues to develop, the selection and application of network protocols will become more diversified and personalized. For manufacturing enterprises, choosing a network protocol that suits their needs will help improve production efficiency, reduce costs, and enhance product quality, thus maintaining an edge in the fierce market competition.