This article’s images are sourced from Mototech Technology.

EtherCAT is a real-time industrial Ethernet technology, where CAT stands for Control Automation Technology.

As a fieldbus system built on Ethernet, EtherCAT features high speed and low data loss rates, achieving a transmission speed of 100M while maintaining low latency and synchronization, making it a popular industrial bus for high-demand real-time network communications.

As a fieldbus system built on Ethernet, EtherCAT has high speed and low data loss rates, allowing for a transmission speed of 100M while maintaining low latency and synchronization, making it a popular industrial bus for high-demand real-time network communications.

EtherCAT hardware can generally be divided into master and slave stations, and compared to other network communication technologies, its slave stations can quickly receive and send information, improving overall communication efficiency.

The EtherCAT master station plays a central role in the entire bus network topology and functionality, where operators typically set and publish the corresponding requirements and scheduling at the master station.The platform universality of the master station software program and its ability to integrate other communication protocols have become key indicators that automation framework builders need to carefully weigh between high standards, ease of interaction, and cost control. Traditionally, for performance reasons, the master station program runs on non-graphical systems like RTlinux, leading to training costs for cross-system learning.

MotoTech Technology has nearly a decade of technical accumulation and practical experience in the field of fieldbus solutions. In response to the objective fact that the domestic demand for fieldbus is rising year by year while specialized network engineers are indeed scarce, they have launched a comprehensive EtherCAT master station software building solution—EC-Master.

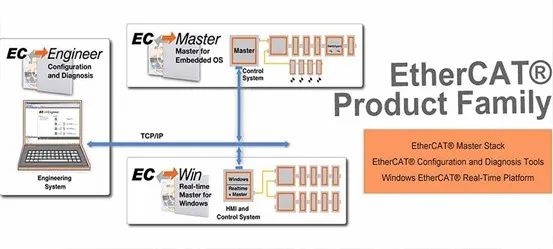

▲EtherCAT Product Development Matrix Diagram

01

What is the EC-Master Protocol Stack?

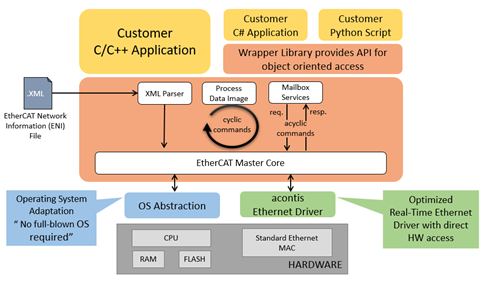

Before introducing the EtherCAT protocol stack, we need to first understand what a protocol stack is. A protocol stack is a specific software implementation of a computer network protocol suite. In simple terms, a protocol stack is the sum of the various layers of protocols in a computer network, reflecting the process of file transmission in a network.

In the protocol suite, each protocol is usually designed for a specific purpose, making the design easier. Since each protocol module typically needs to communicate with two other protocol modules above and below it, they can be imagined as layers in the protocol stack. The lowest-level protocol always describes the physical interaction with hardware, while each higher level adds more features. User applications only deal with the top layer of the protocol. Overall, customers can use the protocol stack to reduce development processes and improve development efficiency.

EC-Master is a protocol stack designed to help users reduce the difficulty of developing EtherCAT master station software, developed and represented by ETG senior member acontis and MotoTech Technology, capable of running on various embedded operating systems: including Linux (with and without real-time), Windows® 7/8/10, VxWorks, QNX, RTX, and many other operating systems. This provides developers with more choices.

The EC-Master protocol stack is compatible with various processors, has rich features and cases, and can be customized using multiple programming languages to edit kernel libraries and required functions. To further facilitate developers, EC-Master can also reduce testing difficulty and improve portability through corresponding visualization simulation software tools and real-time environment building tools. It can be said that EC-Master is a highly regarded software product released by MotoTech Technology.

▲EC-Master Product Structure Diagram

02

What specific functions does EC-Master have?

EC-Master fully complies with the ETG Foundation’s ETG1500 EtherCAT master station specifications, covering many common EtherCAT master station needs. However, EC-Master also includes additional functions that may be required when other controllers, machinery, or automated factories use EtherCAT technology.

The ETG’s 1500 specification defines two types of master stations: Class A and Class B, both of which EC-Master can implement:

Class A

Standard EtherCAT Master Device

Functions

◆ Supports EtherCAT Network Information (ENI) Configuration Files

◆ Supports checking the original configuration against the actual network during startup

◆ Supports periodic process data exchange

◆ Supports CANopen over EtherCAT (CoE) protocol: SDO upload and download, SDO information services (accessing CANopen object dictionary), emergency requests

◆ Supports Servo Profile over EtherCAT (SoE) protocol

◆ Supports Ethernet over EtherCAT (EoE) protocol (virtual switch)

◆ Supports communication between slaves

◆ Supports Safety over EtherCAT (FSoE) slaves

◆ Supports access to slaves’ EEPROM and registers

◆ Rich error diagnosis and detection capabilities

◆ Supports distributed clock (DC) mode synchronization

◆ Supports master and network synchronization (DCM)

◆ Supports ADS over EtherCAT (AoE) mailbox protocol

◆ Supports Transfer over EtherCAT (FoE) mailbox protocol

◆ Supports Vendor over EtherCAT (VoE) mailbox protocol

Class B

Minimized EtherCAT Master Device

Functions

◆ Supports EtherCAT Network Information (ENI) Configuration Files

◆ Supports checking the original configuration against the actual network during startup

◆ Supports periodic process data exchange

◆ Supports CANopen over EtherCAT (CoE) protocol: SDO upload and download, SDO information services (accessing CANopen object dictionary), emergency requests

◆ Supports Servo Profile over EtherCAT (SoE) protocol

◆ Supports Ethernet over EtherCAT (EoE) protocol (virtual switch)

◆ Supports communication between slaves

◆ Supports Safety over EtherCAT (FSoE) slaves

◆ Supports access to slaves’ EEPROM and registers

◆ Rich error diagnosis and detection capabilities

In addition, EC-Master also includes additional features such as frame processing, extended synchronization, hot-swapping, cable redundancy, master redundancy, EoE third-party extension support tools, and UDP Mailbox gateway support, which further expand the use scenarios of EC-Master and better assist in solving data transmission issues. If needed, please contact MotoTech Technology for more information.

03

What are the advantages of EC-Master?

Compared to open-source master station software development products, EC-Master offers better stability and more features.

The main advantages of EC-Master are as follows:

◆ Low CPU load while maintaining high performance for fast update rates

◆ Applicable to various operating systems

◆ Supported CPU architectures include x86 (32-bit and 64-bit), ARM (32-bit and 64-bit), and PowerPC (PPC)

◆ Compatible with many processors from well-known brands such as Intel, Texas Instruments, ST, Broadcom, Nvidia, Renesas, NXP, Xilinx, and Infineon

◆ Reliable after-sales service to assist in building complete system integration solutions and personalized custom control systems

◆ A wealth of stable case studies to help users reference and use: for example, EC-Master has been deployed in KUKA Robot Control and controllers like Yaskawa, Lenze, and Omron to achieve practical applications.

In addition to the main advantages, EC-Master also has more comprehensive functions, diversified auxiliary tools, and cost-effective pricing as other objective advantages. Specific scenarios and requirements vary; for more targeted solutions and related content, please feel free to contact the designated distributor of EC-Master in China—MotoTech Technology. Professional technical and business personnel will quickly connect with those in need to assist with the implementation and application of EC-Master.

04

What auxiliary tools does EC-Master have?

MotoTech Technology not only distributes the EC-Master protocol stack product itself in the Greater China region but also distributes multiple supporting products.

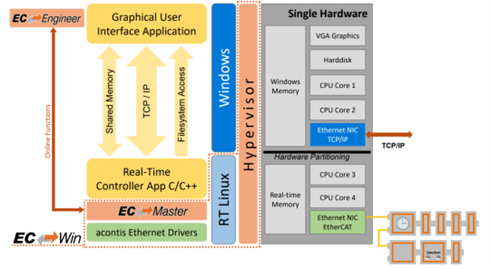

Among them, EC-Win/LxWin is a system-level real-time solution aimed at meeting the real-time needs of EC-Master. This excellent real-time solution not only assists users with real-time needs for EtherCAT but also helps other users add real-time functionality to Windows systems, assisting customers in building and implementing application environments through visual management tools and providing synchronization testing functionality, significantly reducing development costs.

▲EC-Win Real-Time Solution Structure Diagram

Additionally, apart from the EC-Win/LxWin solution, under the guiding principle of “people-oriented, facilitating human-machine interaction,” EC-Master developers have also developed and maintained several visualization testing applications:

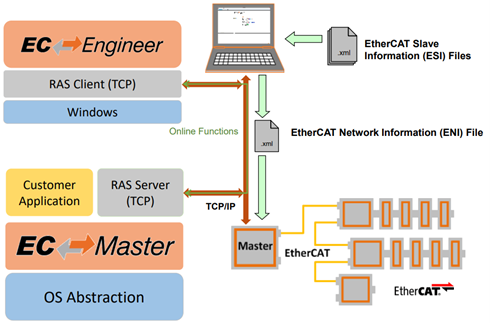

EC-Engineer—a professional EtherCAT network configuration and diagnostic tool. EtherCAT slaves only need to connect to a Windows PC running EC-Engineer or directly to the master station protocol stack control system to use EC-Engineer to complete EtherCAT configuration work offline at any location or perform “online” operations by connecting to a real EtherCAT network on the machine. This software also has a web version—EC-Engineer Web for user experience.

▲EC-Engineer Application Diagram

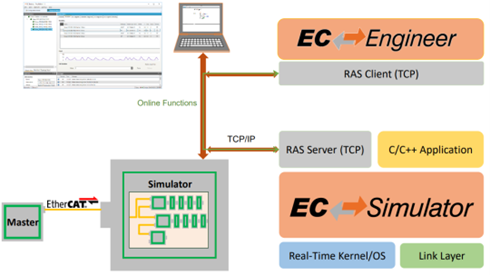

EC-Simulator—an efficient slave simulation tool. EC-Simulator simulates EtherCAT slave devices to achieve virtualization of the EtherCAT network, allowing the EtherCAT master station application to run without real EtherCAT slave hardware.

▲EC-Simulator Application Diagram

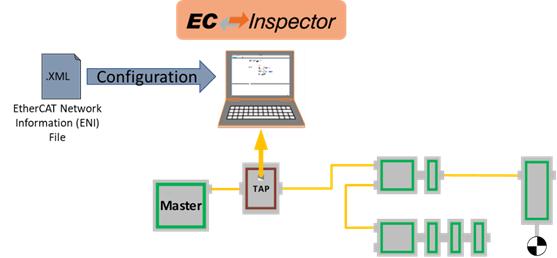

EC-Inspector—a reliable EtherCAT communication analysis software. EC-Inspector is a software tool that analyzes and monitors EtherCAT network data frames from an external perspective. This program can operate independently of the main controller and can be used with EtherCAT master stations from any manufacturer (Beckhoff, Omron, Bosch-Rexroth, Lenze, acontis, etc.). EC-Inspector analyzes the complete data communication between the master station and EtherCAT slaves through a TAP device inserted between the master and slaves.

▲EC-Inspector Application Diagram

All of the above software products have undergone rigorous selection by leading companies in the automation market and industry, featuring numerous practical application cases that assist users in deploying EtherCAT services more conveniently, stably, and safely.

Where to find more information about EC-Master?

MotoTech Technology, as the designated distributor of EC-Master, has accumulated years of experience in project implementation and solution provision. More information about EC-Master can be found on MotoTech Technology’s official website, and customers can also directly and efficiently communicate with professional technical staff via email or phone to obtain more localized solutions and information.

Official website:

www.motrotech.com

Email:

Phone:

010-62740270

– END –