Technical exchange, join the group here

Technical exchange, join the group here Sales procurement, join the group here

Sales procurement, join the group herePreface

(1) Profinet

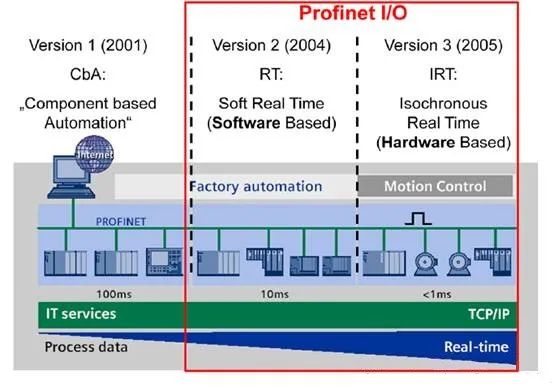

The diagram below shows the hardware catalog of TIA Portal with SIPLUS extreme components. First, let’s take a look at Profinet. As shown in the diagram, Profinet is divided into three versions:

-

Profinet CbA -

Profinet RT -

Profinet IRT

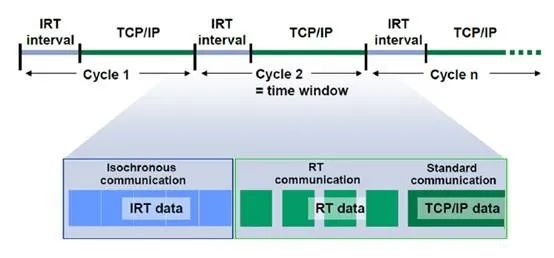

These three different versions correspond to Profinet’s three different real-time characteristics. CbA refers to Component-based Automation, with a real-time response time of 100ms, typically used in general industrial control scenarios where real-time requirements are not high. RT refers to soft real-time, used for factory automation at the PLC control level, with a response time of 10ms, while IRT refers to synchronous real-time, which can also be called hard real-time, with a response time of less than 1ms, satisfying the real-time and synchronization requirements of most motion control fields.Profinet’s RT and IRT can be illustrated with the diagram below:

These three different versions correspond to Profinet’s three different real-time characteristics. CbA refers to Component-based Automation, with a real-time response time of 100ms, typically used in general industrial control scenarios where real-time requirements are not high. RT refers to soft real-time, used for factory automation at the PLC control level, with a response time of 10ms, while IRT refers to synchronous real-time, which can also be called hard real-time, with a response time of less than 1ms, satisfying the real-time and synchronization requirements of most motion control fields.Profinet’s RT and IRT can be illustrated with the diagram below:

To ensure absolute real-time performance, Profinet IRT isolates the data transmission channel from regular Ethernet. This means that IRT does not use the TCP/IP protocol to transmit real-time data, similar to EtherCAT.

To ensure absolute real-time performance, Profinet IRT isolates the data transmission channel from regular Ethernet. This means that IRT does not use the TCP/IP protocol to transmit real-time data, similar to EtherCAT.(2) EtherCAT

(3) EtherCAT vs Profinet IRT

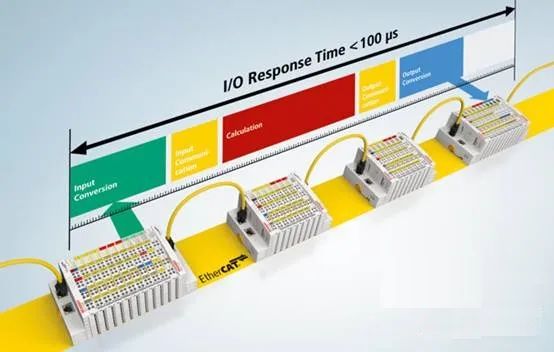

EtherCAT uses a technique that can be described as “on the fly“, optimizing the Ethernet packet structure for distributed IO. Communication is fully supported by hardware chips to ensure maximum performance; if it is a pure EtherCAT network, there is no need for switches, and the diagnostic functions are very powerful.

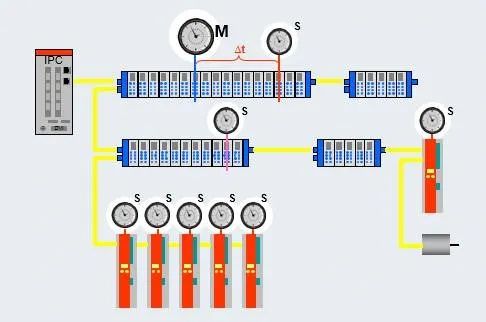

EtherCAT has a very flexible topology structure, which can be linear, star, tree, mixed, etc., and can be used for almost any connection method. At the same time, EtherCAT supports cable redundancy, theoretically allowing each EtherCAT network to support 65535 nodes, without being affected by the topology structure.

EtherCAT is not affected by slave devices and topology structures, allowing for flexible network deployment. There is no need to manually set slave addresses, nor manage IP or MAC addresses. Slave addresses are automatically generated, and if new slaves are added, there is no need to manually update addresses, thus avoiding address conflicts, making EtherCAT a good user experience.

Since the first draft of the IEC61158 standard in 2005, EtherCAT has undergone 46 technical changes, mostly errata. Each change can be traced back using errata sheets, and documents can be downloaded from the ETG website. Maintenance testing tools have been continually improved, but no fundamental changes have occurred. EtherCAT has made some parameter changes, but its technical version has not changed since its release.

Profinet does not provide a detailed errata sheet, and its three versions, especially the IRT version, have been changing continuously. Since Profinet is not an open bus, it is understandable that detailed information is not provided to users during parameter changes or technical transformations. However, from a technical stability perspective, open buses are more user-friendly.

(4) Conclusion

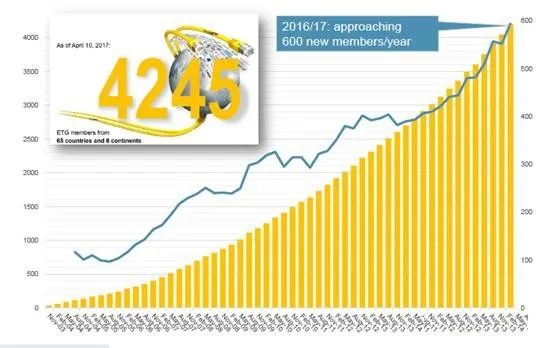

Due to the differences in bus technology and application backgrounds, we cannot say that one bus’s performance is superior to another. Generally speaking, market users can clarify issues. EtherCAT has gained a large number of users due to its openness. From this perspective, Profinet is unlikely to achieve the glory of Profibus in the near future, as a traditional field bus, Profibus is also open.EtherCAT’s rapidly growing user base:

In line with current trends, EtherCAT has also begun to integrate with IoT technology. Conceptually, EtherCAT has immersed itself into IoT technology, and even ETG claims that EtherCAT itself is IoT. The future of industrial Ethernet buses is very bright; traditional field buses have lagged far behind industrial Ethernet in terms of data volume and transmission speed. For example, CAN is typically used in the automotive industry. With the development of the automotive industry, cars are increasingly seen as mobile internet terminals. Can CAN still meet the demands for high-speed and large data transmission? Some automotive manufacturers are already at the forefront of technology; for instance, Toyota has begun to adopt EtherCAT technology. The traditional bus competition in the field of industrial automation will undergo fundamental changes with the advancement of internet technology.

What Everyone Is Watching

[Video] How do German engineers make PLC cabinets?

[Video] How do German engineers make PLC cabinets?

[Video] How are German WITRON electrical cabinets produced?

[Video] How are German WITRON electrical cabinets produced?

[Video] What is the office environment like for German engineers?

[Video] What is the office environment like for German engineers?

[Video] Why is PROFINET better than PROFIBUS?

[Video] Why is PROFINET better than PROFIBUS?

Reply “V18” to get the latest version of the TIA Portal bundle (including authorization)

Reply “V18” to get the latest version of the TIA Portal bundle (including authorization)