At the Breezm experience store in Manhattan, New York, a fashion blogger is obtaining facial data from 1200 key points through 3D scanning. Fifteen minutes later, a custom frame model based on EOS SLS technology has been generated — with the nose pad angle precisely at 12°15’ and the temple bend perfectly fitting the ear contour, all thanks to the precise molding capabilities of EOS PA 2200 material. This scene is being played out in various fashion labs around the world, as EOS, the invisible champion of industrial 3D printing, empowers a paradigm revolution in the traditional eyewear manufacturing industry through technology.

3D Printing Unlocks New Dimensions in Design

From Standardization to Personalization

The traditional injection molding process is limited by mold costs and production processes, often leading to a “same old, same old” situation in frame design. However, EOS’s Selective Laser Sintering (SLS) technology allows for the free creation of complex geometric structures by layer-by-layer melting of powder materials with a laser. For example, the Belgian luxury brand Hoet Couture uses the EOS M 290 metal 3D printer to create titanium alloy frames with integrated honeycomb lattice structures, achieving extreme weight reduction while ensuring strength. This disruptive design transforms the frame from merely an accessory into a “wearable work of art.”

Additionally, EOS technology supports on-demand customization. The American brand Breezm integrates 3D scanning, AI data, and EOS polymer 3D printing to achieve a full process of “face-fitting customization”: consumers only need to undergo facial scanning, and the system can generate a custom frame model, with personalized products fitting their facial contours delivered within 10-14 days. This model not only shortens the product launch cycle from 6 months to a few weeks but also drives a 60% increase in annual sales, with over 60,000 pairs of glasses sold.

3D Printing Makes Fashion More Eco-Friendly

Sustainable Revolution

In the context of “carbon neutrality” becoming a global consensus, EOS technology injects green genes into the eyewear industry. A full life cycle analysis (LCA) conducted by the German brand YOU MAWO in collaboration with EOS and Fraunhofer EMI shows that its 3D printed frames have a carbon footprint 58% lower than traditional acetate frames, with waste generation reduced by 80%. This is due to the characteristics of 3D printing, which maximizes material utilization with zero mold waste — unsintered powder can be reused, while traditional injection molding has a material waste rate exceeding 30%.

Moreover, EOS is pushing the sustainable boundaries of material innovation. The 100% recycled aluminum AlSi10Mg material, set to launch in 2025, reduces carbon dioxide emissions by 83% compared to primary aluminum production, while maintaining mechanical properties comparable to traditional materials. This material has been applied in high-end sports eyewear, achieving a perfect balance between lightweight and durability. As YOU MAWO’s Executive Director Sebastian Zenetti states: “EOS technology not only meets our high-quality standards but also supports our pursuit of sustainable production.”

From Luxury Goods to the Mass Market

EOS’s technology matrix is covering different market levels:

1

Luxury Sector: Dior collaborates with Thélios to create 3D printed sunglasses that transform the iconic Cannage pattern into a wearable lattice structure, achieving mass production through SLS technology, with a single pair priced over $2000, redefining the manufacturing logic of high-end accessories.

△Thélios uses Selective Laser Sintering (SLS) 3D printing technology to produce Dior 3D sunglasses

2

Cutting-edge Technology: The Chinese brand BRAGi utilizes the EOS FORMIGA P 110 Velocis system and PA 2200 material to build a “scan-design-print” closed loop, delivering over 30,000 pairs of custom glasses in more than 10 countries, with frame fitting errors of less than 0.1mm, significantly enhancing wearing comfort.

3

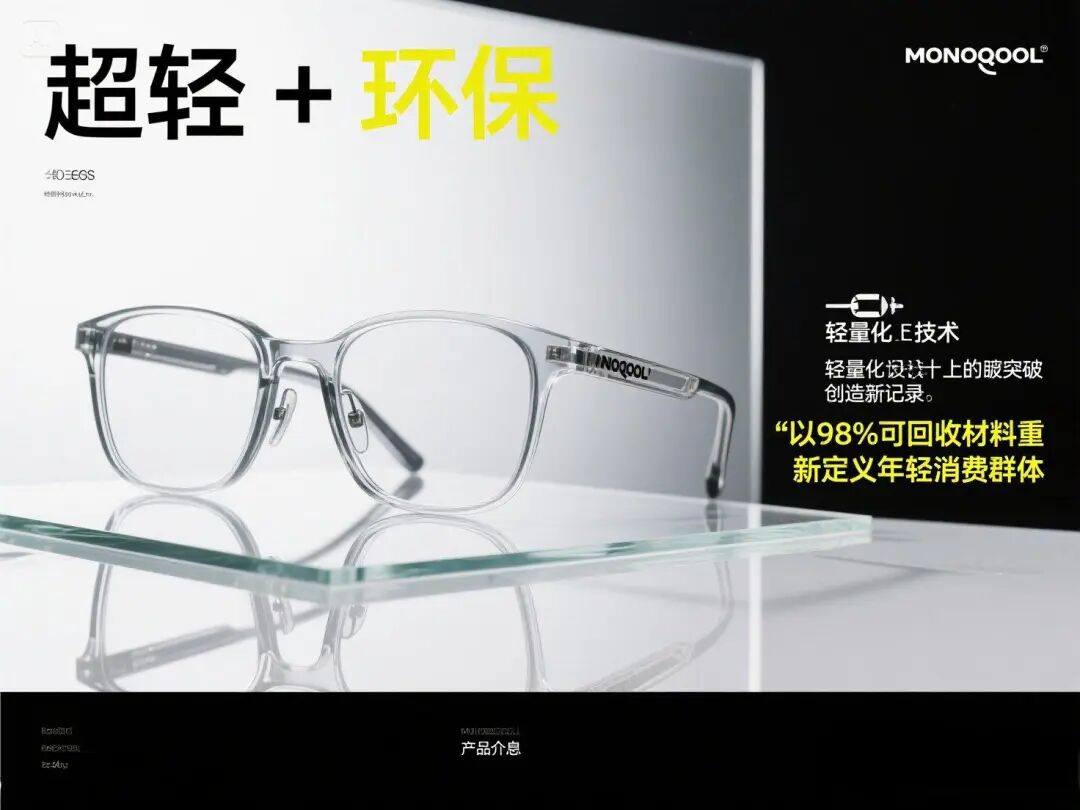

The Danish brand MONOQOOL uses EOS technology to reduce frame weight to 4 grams, setting a world record while achieving 98% material recyclability, opening up the young consumer market with “ultra-light + eco-friendly” products.

Triple Breakthrough in Data, Materials, and Ecology

Industry Transformation

The underlying logic of this transformation lies in the deep integration of data-driven and material revolutions. EOS’s parametric design software allows designers to adjust over 20 frame parameters in real-time, while the pure white base of PA 2200 material supports over 100 color post-processing options, completely breaking the color limitations of traditional processes. More importantly, EOS’s global service network (covering 35 countries) and localized support enable brands to quickly implement 3D printing solutions without the need to build complex production lines.

315

According to market forecasts, the global 3D printing eyewear market is expected to reach $1.85 billion by 2024, and is projected to exceed $2.2 billion by 2025, with customized products accounting for over 68%. On the policy front, departments such as the National Health Commission of China have introduced special policies, with over 1 billion yuan invested in cities like Shanghai to support the research and development of 3D printing and other optical technologies, further accelerating industry penetration.

Conclusion

From the runways of Paris Fashion Week to eyewear stores on Asian streets, EOS is reconstructing the value chain of the eyewear industry with 3D printing technology. For consumers, this means a more fitting and unique wearing experience; for brands, it represents a strategic opportunity to break through homogenized competition and achieve sustainable development; and for the entire industry, it is a paradigm revolution from “manufacturing” to “intelligent manufacturing.” As EOS’s polymer business development manager Dave Krzeminski states: “We are not just producing frames; we are creating the future of consumer experience.” When technology and aesthetics perfectly merge, eyewear will no longer be standardized industrial products, but rather unique personal statements for everyone.

END

Some content in this article is sourced from the internet. If there is any infringement, please contact this public account for deletion.