As two core components in the field of industrial control, microcontrollers and PLCs each have unique characteristics and applicable scenarios. Below is an in-depth analysis of the two:

1. Definition and Structural Composition

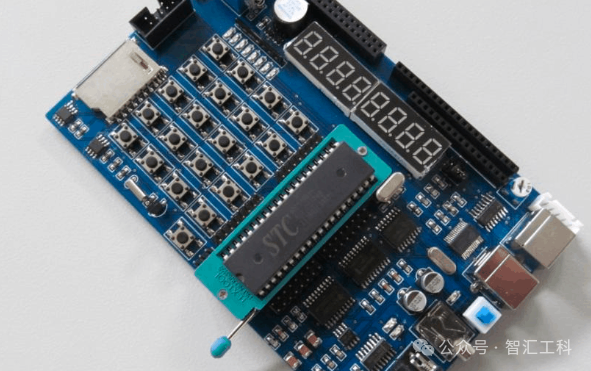

1. Microcontroller:

● Definition: A microcontroller, also known as a microcontroller unit (MCU), is an integrated circuit chip. It is a small and complete microcomputer system that integrates a central processing unit (CPU) with data processing capabilities, random access memory (RAM), read-only memory (ROM), various I/O ports, an interrupt system, timers/counters, and other functions onto a single silicon chip using very large scale integration (VLSI) technology.

● Structural Composition: The basic structure of a microcontroller includes the CPU, memory (RAM/ROM), I/O interfaces, timers/counters, interrupt systems, and system buses.

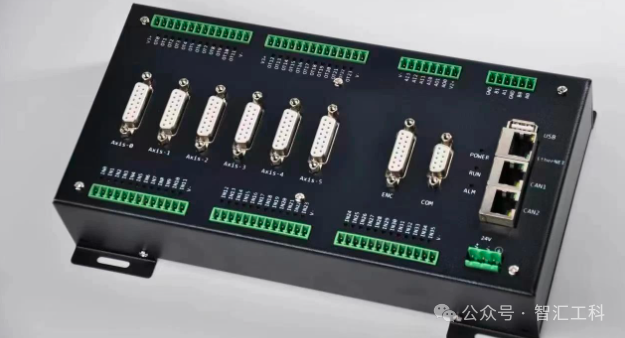

2. PLC (Programmable Logic Controller):

● Definition: A PLC is a digital computing control system specifically designed for industrial environments. It implements logical operations, sequential control, timing, and counting functions through programmable memory, and controls mechanical equipment using digital or analog input/output modules.

● Structural Composition: The basic components of a PLC include the CPU, memory, I/O modules, power supply module, and communication module. These components work together to enable the PLC to efficiently and stably execute various control tasks.

2. Functions and Performance

1. Microcontroller:

● Processing Speed and Stability: The processing speed and stability of microcontrollers are relatively weak, making them susceptible to environmental interference, suitable for applications with lower control precision requirements.

● Programming and Debugging: Microcontrollers typically use programming languages such as C and assembly language, which have longer development cycles and higher technical requirements for developers.

● Application Fields: Microcontrollers are widely used in consumer electronics, smart homes, automotive electronics, and other fields, suitable for small-scale, low-power control tasks.

2. PLC:

● Processing Speed and Stability: PLCs are designed for industrial environments, offering high reliability and strong anti-interference capabilities, capable of stable operation under harsh conditions.

● Programming and Debugging: PLCs use graphical programming languages (such as ladder diagrams, function block diagrams, etc.), making programming simple and intuitive, suitable for rapid development and debugging.

● Application Fields: PLCs are primarily used in industrial automation control, such as production line control and machinery control, suitable for scenarios requiring high reliability and complex logical control.

3. Interfaces and Communication

1. Microcontroller:

● Typically uses GPIO and other interfaces to connect external components, with relatively simple communication methods, suitable for small-scale systems.

2. PLC:

● Equipped with various communication interfaces (such as Ethernet, RS-232, RS-485, etc.), supporting complex industrial communication protocols, suitable for large-scale system integration.

4. Cost and Scalability

1. Microcontroller:

● Lower cost, suitable for mass production, but requires strong R&D capabilities and industry experience to ensure system stability.

● Limited interfaces, requiring external circuit expansion.

2. PLC:

● Higher cost, but offers good scalability and modular design, supporting modular expansion and capable of handling hundreds of signals, suitable for complex system integration and expansion.

5. Development Trends

1. Microcontroller:

● High Performance: With advancements in manufacturing processes, the performance of microcontrollers will continue to improve, with faster operating speeds, lower power consumption, and higher integration levels.

● Diverse Functions: Microcontrollers will integrate more functional modules, such as wireless communication, image processing, artificial intelligence, etc., to meet more complex application needs.

● Intelligence: With the development of artificial intelligence technology, microcontrollers will possess stronger learning and reasoning capabilities, achieving higher levels of intelligent control.

2. PLC:

● Greater emphasis on integration and innovation with other technologies, such as the combination with artificial intelligence, big data, and cloud computing, will further enhance the control capabilities and intelligence of PLCs.

● Applications in special environments will become more widespread, with stability and reliability under extreme conditions such as high temperature, high pressure, and strong magnetic fields being further improved.

In summary, microcontrollers and PLCs exhibit significant differences in definitions, structural compositions, functions and performance, interfaces and communication, costs and scalability, as well as development trends. When choosing which controller to use, one should comprehensively consider specific application scenarios, control requirements, and cost budgets.