All the information you need to know about Bluetooth Low Energy (BLE) in 2020

We live in a space where fantasy and reality reflect each other, technology and culture intertwine, individuals and the whole blend, and privacy and transparency are balanced. In a world of interconnected devices, everything tends towards excellence and the perfect performance of wearable devices, which are gradually becoming a reality around us.

Wearable devices are often defined as one of the most direct applications of IoT technology. With the continuous development of innovative technologies, the forms of wearable devices are becoming increasingly diverse, driving the commercialization of the entire IoT industry chain. Bluetooth Low Energy (BLE) is the most widely used wireless connection technology in wearable devices. Over the past decade, related use cases have expanded from connecting computer peripherals to full communication with wearable devices and many other applications. The latest Bluetooth® specifications (5.0, 5.1, 5.2) further cover more applications in the IoT field.

Compared to classic Bluetooth, BLE significantly reduces power consumption and costs while maintaining the same communication range, making it an ideal choice for connecting different sensors, peripherals, and control devices. From smart homes, smart cities, to smart industries, BLE provides humans with an infinite array of smart living scenarios. Everything that was once simple and fragmented around us is now starting to connect and become intelligent.

Undoubtedly, with the development and promotion of low-power Bluetooth technology, “human-machine interaction” and even “human-machine symbiosis” will become the norm in our present and future lives.

As low-power Bluetooth smart devices increasingly emphasize compact designs and high integration, the standards for their testing and measurement methods have also become higher. Therefore, Over-The-Air (OTA) testing will undoubtedly gain more attention. However, to optimize testing procedures, the best choice is to complement all methods.

The Bluetooth Special Interest Group (Bluetooth SIG) ensures that devices can work together and maintain qualified quality and performance through various test cases in the certification process. After completing the declaration, they can obtain the Bluetooth label to enter the market.

Let’s first get acquainted with several testing methods for low-power Bluetooth:

Direct Test Mode

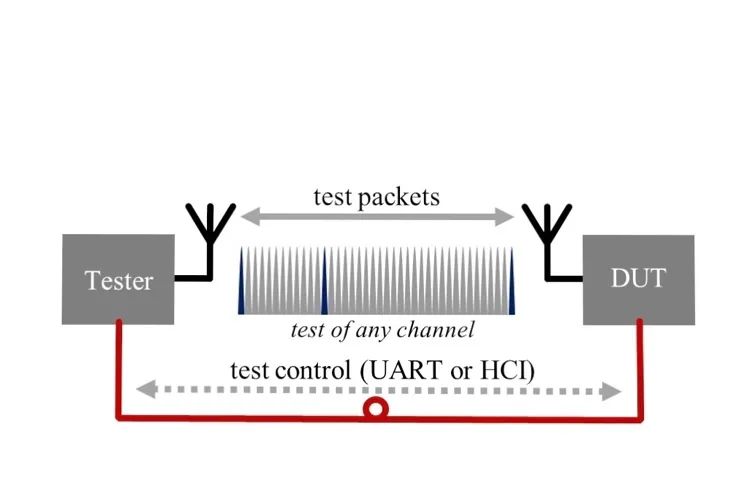

Direct Test Mode (DTM) is a mode used for testing the RF performance of low-power Bluetooth and is part of the Bluetooth core specification. Any chip that complies with the Bluetooth core specification can perform DTM testing.

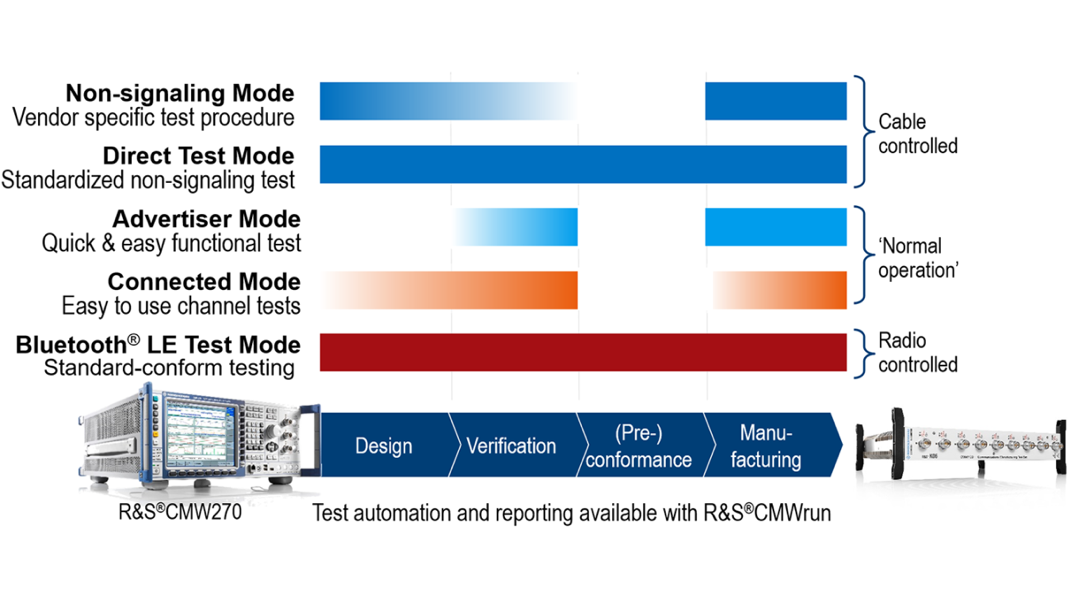

DTM connects the testing instrument directly to the Bluetooth device control interface, executes test items, and automatically completes the interaction commands and Bluetooth parameter settings between the Bluetooth module. DTM can be used in R&D, pre-certification, and consistency production, and is currently the Bluetooth low-power testing method compliant with BlueSig specifications. However, the drawbacks are also quite obvious; the DTM method requires additional control lines to test the Bluetooth device under test via HCI or UART protocols, which adds extra complexity, especially for laboratories that need to test different chips, making it quite painful. Moreover, different chips have varying degrees of openness for DTM, which creates an urgent need for new methods to improve the testing of low-power Bluetooth products.

Broadcast Test Mode

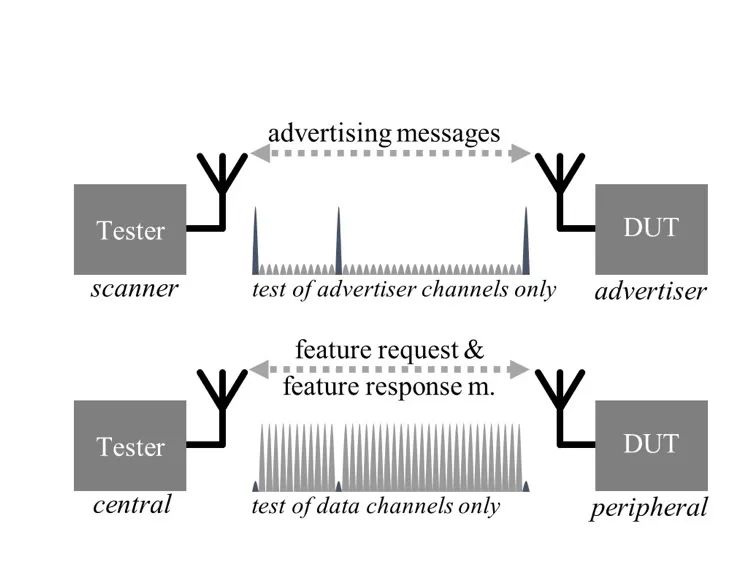

Some low-power Bluetooth devices on the market are very small. If DTM testing is required, the product would need to be destroyed, and some low-value products do not reserve testing interfaces. For example, some smart wristbands and mobile tags, R&S®CMW therefore provides an RF testing method under broadcast mode. That is, under normal operating conditions, R&S®CMW listens and responds to the high, medium, and low channels of Bluetooth devices broadcasting on three broadcast channels, performing transmission and reception measurements, and determining the Packet Error Rate (PER) and sensitivity levels.

The advantage of the broadcast test mode is that all low-power Bluetooth devices can be tested without additional product configurations and cable connections. However, this mode only allows testing of the three broadcast channels based on any broadcast data packets, and the testing time cannot be controlled, entirely depending on the signal broadcast cycle of the device under test, thus only suitable for production testing, quality inspection, and quick functional testing of overall performance.

Connection-Based Testing

For chamber testing and simple functional testing, using a real connection between the DUT and the comprehensive tester is the simplest solution. This method does not require any specific modification or configuration of the device. In RF testing, the tester acts as the master device, establishing a connection with the device under test, using predefined control commands to test the Bluetooth device, and the tester can complete loop testing on all data channels.

However, the disadvantage of this mode is that it cannot perform RF testing using data with dedicated Payload lengths and specific Patterns according to the low-power Bluetooth testing specifications, nor can it test on the broadcast channel.

New BLE Testing Mode

R&S®CMW not only helps users select the mode that matches their applications from the above three BLE RF testing modes but also combines the broad testing mode and connected mode to develop a new Bluetooth low-power OTA testing solution. This solution addresses the difficulties faced by the aforementioned three testing modes when testing low-power Bluetooth devices. Currently, Rohde & Schwarz is actively promoting this new testing method to become a standardized approach.

To achieve excellent results, one must first equip the right tools. The R&S®CMW270/CMW500/CMW100 series comprehensive testers provide the most comprehensive Bluetooth testing methods, meeting various different devices and testing needs, tracking the latest Bluetooth testing specifications, and providing automated testing tools, achieving a turnkey solution from production to R&D to pre-certification. Moreover, it can support features of various versions, such as Bluetooth positioning, classic Bluetooth audio, and the latest Bluetooth low-power LC3 encoding.

Testing for Developing Bluetooth Technologies

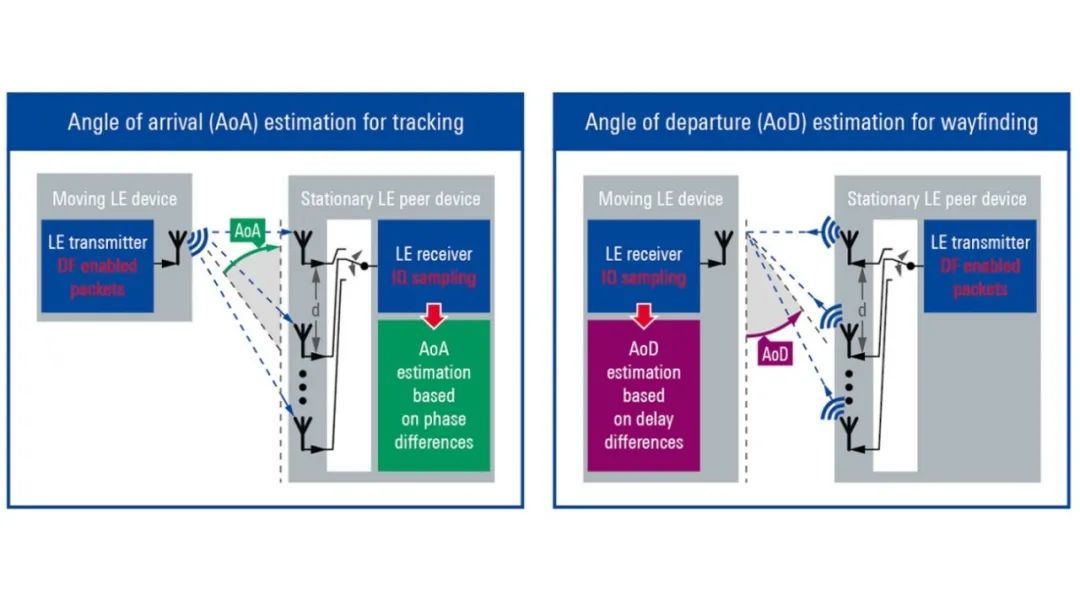

New forms and use cases of Bluetooth technology will continue to emerge. In recent years, this technology has improved in data rates and ranges, introducing features such as direction finding, native support for low-power Bluetooth audio transmission, and power control. This will rapidly promote the development of Bluetooth landmark information, item tracking, asset tracking, and navigation, targeting the high-precision positioning market.

According to the latest predictions from ABI Research and insights from other analytical agencies, the global shipment of Bluetooth devices will reach 5.4 billion units in 2023, with 90% of Bluetooth devices adopting low-power Bluetooth, and one-third of the shipped devices will use low-power Bluetooth single-mode modules.

The continuous development of technology requires the development and optimization of corresponding testing and measurement solutions. Meanwhile, the team supporting Bluetooth products is also growing increasingly large, necessitating a large number of tests around these products. This is also the key to gaining an advantage in the fierce market competition in the future and remaining undefeated.

About Rohde & Schwarz

Rohde & Schwarz is an independent international technology company that develops, produces, and sells innovative communication, information, and security products for professional users. The company’s main business areas include testing and measurement, broadcasting and media, aerospace|defense|security, and network information security, covering various industries and government market branches. As of June 30, 2019, Rohde & Schwarz had approximately 12,000 employees. The company is headquartered in Munich, Germany. Globally, the company has subsidiaries in over 70 countries and regional centers in Asia and the United States.

For more information, visit https://www.rohde-schwarz.com.cn

For technical and product information, call 400-650-5896

Scan to follow the official WeChat account of Rohde & Schwarz