Over 70,000 friends have followed this industrial control WeChat platform:Technical sharing, Learning exchange, Industrial control videos

PLCs have strong self-diagnostic capabilities. When there is a fault in the PLC itself or in peripheral devices, the diagnostic indicator function of the PLC, indicated by the on/off state of the LEDs, can be used for diagnosis.

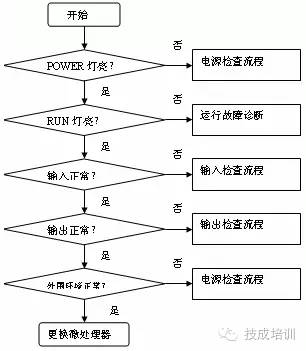

I. PLC Fault Diagnosis Flowchart

1. General Inspection

Use the general inspection flowchart to identify the general direction of the fault, gradually refining it to pinpoint the specific fault, as shown in Figure 1.

Figure 1

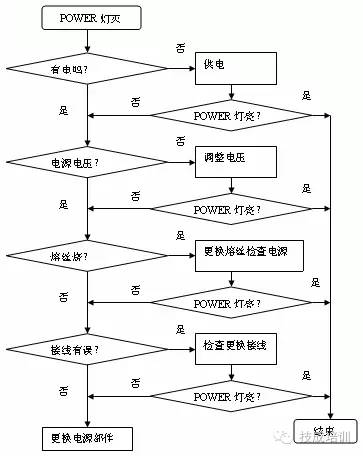

2. Power Supply Fault Inspection

If the power supply indicator is off, the power supply system needs to be checked. The inspection flowchart is shown in Figure 2.

Figure 2

Figure 2

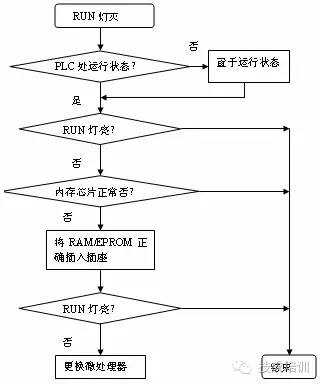

3. Operational Fault Inspection

If the power supply is normal but the operation indicator is off, it indicates that the system has terminated normal operation due to some anomaly. The inspection flowchart is shown in Figure 3.

Figure 3

4. Input/Output Fault Inspection

The input/output is the channel through which the PLC communicates with external devices. Its normal operation is related not only to the input/output units but also to the status of connection wiring, terminal blocks, fuses, and other components. The inspection flowcharts are shown in Figures 4 and 5.

5. External Environment Inspection

The environmental factors affecting PLC operation mainly include temperature, humidity, noise, dust, and corrosive acids and bases.

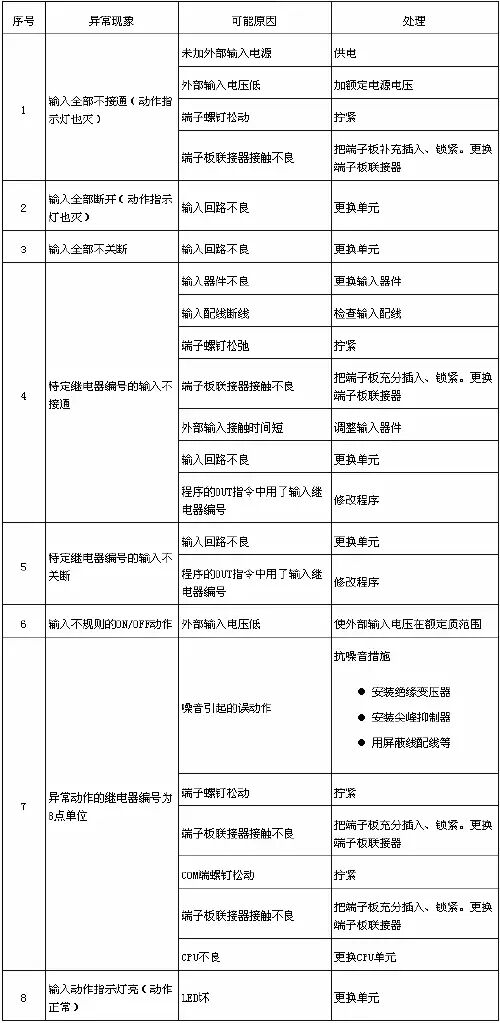

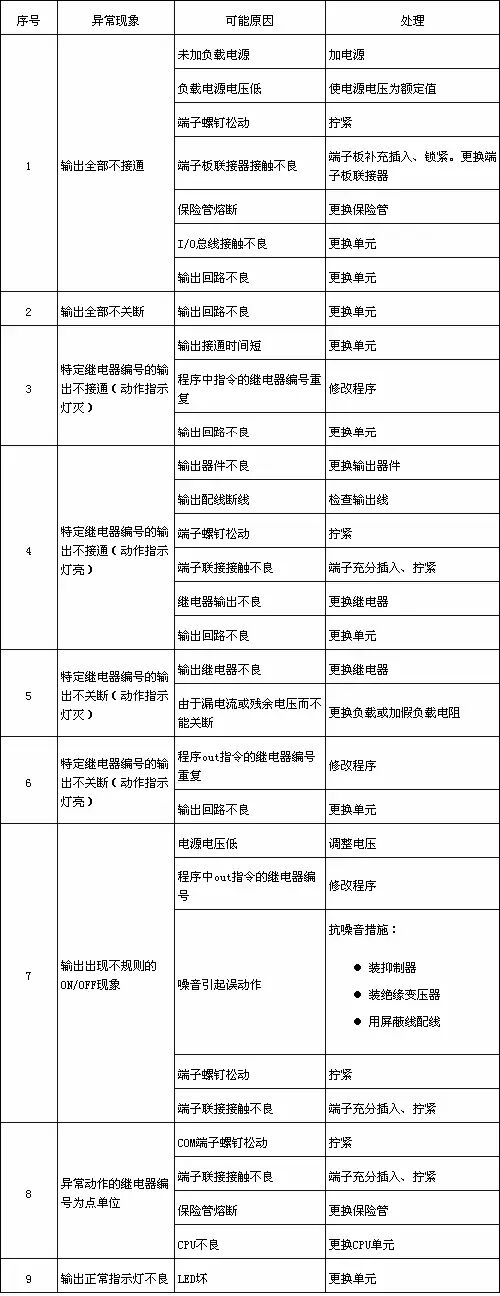

II. Fault Handling for Programmable Controller Input/Output Units

Table 1: Fault Handling for Programmable Controller Input Units

Table 2: Fault Handling for Programmable Controller Output Units

Author: Wang Wenpeng

Graduated in 2006 from the School of Mechanical Engineering, Wuhan University of Science and Technology, with over 10 years of experience in the mechanical industry. Title: Engineer.

Employed at: Wuhan Iron and Steel Corporation

✌ Good materials are worth sharing!

Long press to recognize the QR code

Follow for more exciting content

Click to read the original text to view history