When it comes to the S7-200SMART PLC, it typically uses Ethernet communication to exchange data. For instance, the Weilin touch screen now supports communication control with the 200SMART via the network port. But can the 9-pin serial port still communicate with the Weilin touch screen? The answer is definitely yes. So how do we perform the operation? What should we pay attention to during communication? Let’s dive into the technical encyclopedia.

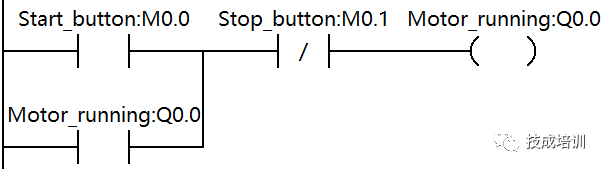

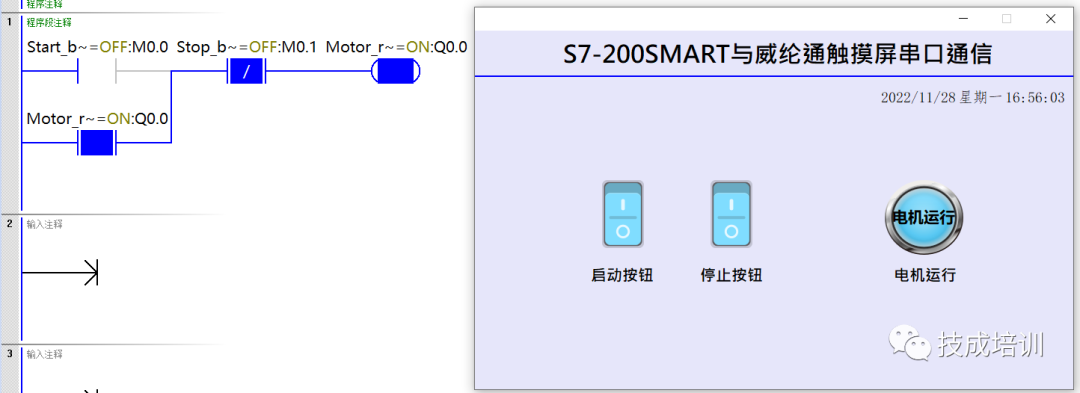

Step 1: Write the Start/Stop Control Program

Friendly reminder: PLC input points use internal M addresses as the touch screen control addresses. The touch screen cannot directly associate with input points I; it must use M or V addresses for conversion.

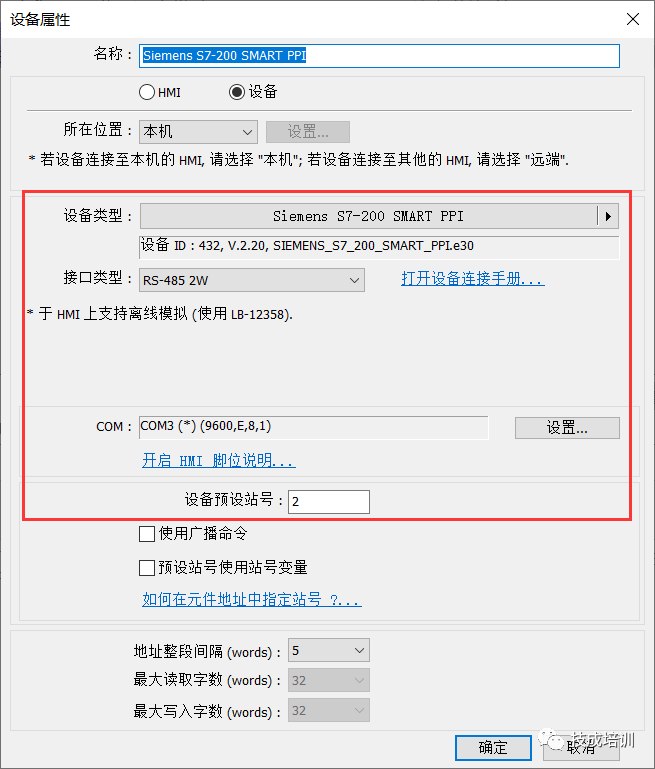

Step 1: Click to Add Device/Server

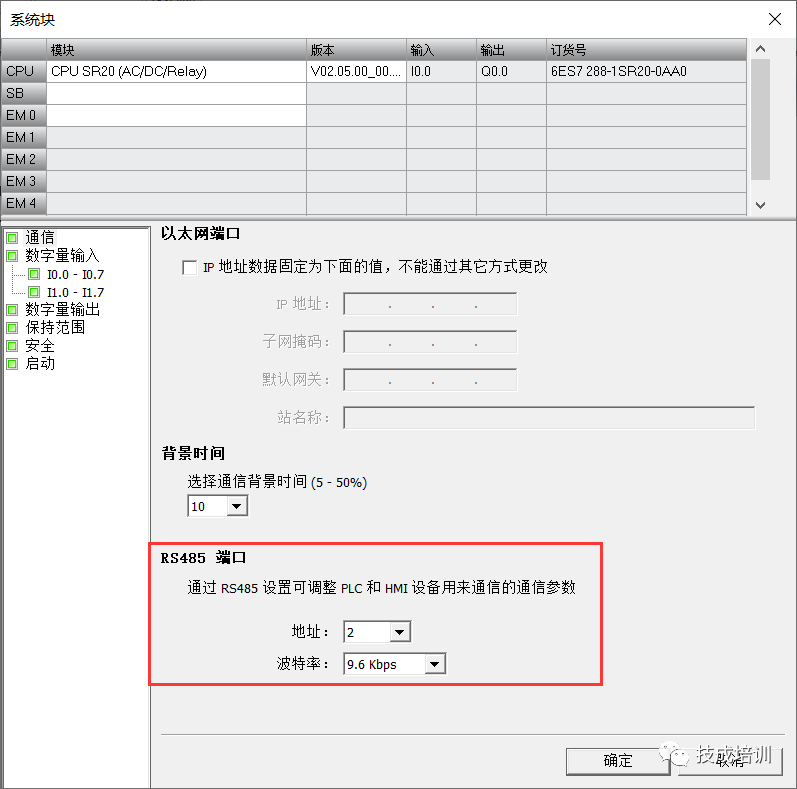

Step 2: Set Device Properties Corresponding to Parameter Options

Device Type: Siemens S7-200 SMART PPI

Interface Type: RS-485 2W

COM: Must match the programming cable plugged into the computer’s COM port, here it’s COM3.

Baud Rate: Must be consistent with the programming software, here it’s 9600, other parameters can remain default.

Device Preset Station Number: Must be consistent with the programming software, here it’s 2.

Step 3: Return to the System Parameter Interface and Click Confirm

Step 1: Associate Buttons and Indicator Lights with PLC Corresponding Addresses

M0.0=Start Button

M0.1=Stop Button

Q0.0=Motor Running

Step 2: Demonstration Effect

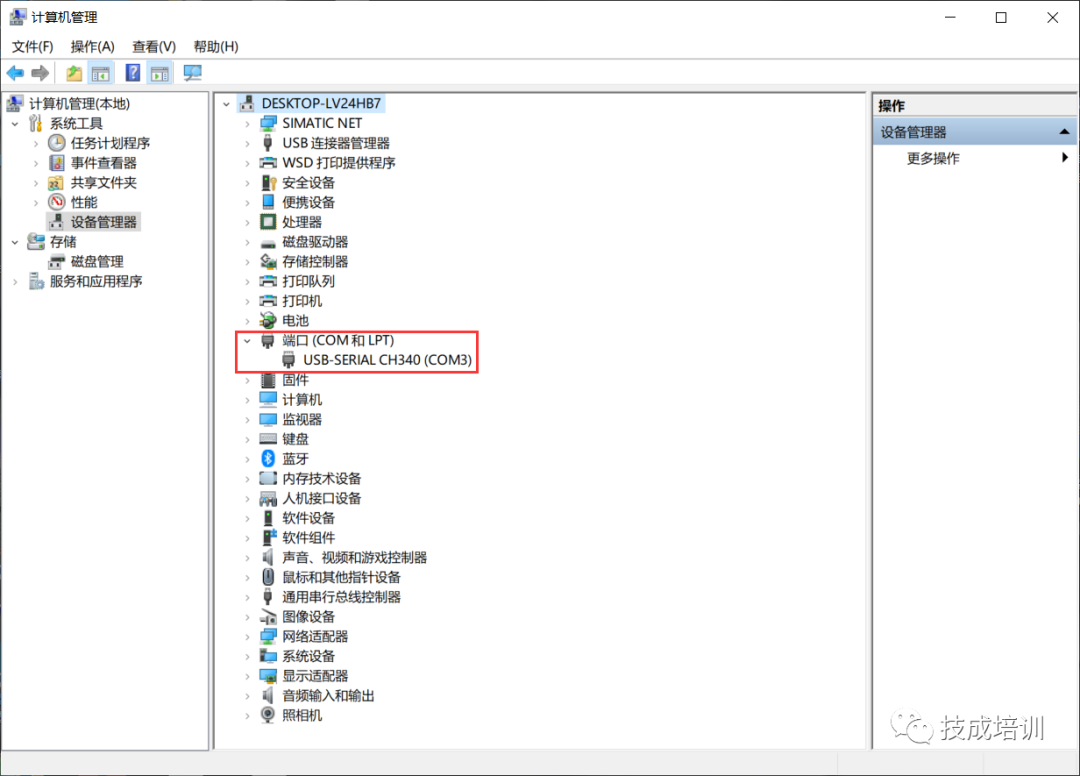

1. The Weilin serial port online simulation must use a programming cable with a COM port. If using the original Siemens USB-PPI cable, which does not have a COM port, it cannot connect for simulation.

Programming cable with COM port, as shown below:

Siemens original PPI cable or programming cable without COM port, as shown below:

2. When connecting, the COM port, baud rate, and device preset station number must match those of the PLC and programming software; otherwise, communication will fail.

This is the communication between the Weilin touch screen and the S7-200SMART PLC. If you still have doubts, please scan the QR code below for detailed live broadcasts or courses:

Source: Technical Training Network Original, Author: Xu Chenshuang; Unauthorized reproduction is prohibited, violators will be prosecuted!

Three must-have tools for electrical workers, just one click on WeChat to use!

[Collect] The “way out” for a ten-year veteran electrician, the secret to earning over ten thousand a month!

Which of the five major electrical drawing software (CAD, Eplan, CADe_simu…) do you choose?

The latest electrical version CAD drawing software, with a super detailed installation tutorial!

The latest electrical drawing software EPLAN, with a super detailed installation tutorial!

Common problems for beginners using S7-200 SMART programming software (with download link)

Comprehensive electrical calculation EXCEL sheets, automatically generated! No need to ask for electrical calculations!

Basic skills of PLC programming: Ladder diagrams and control circuits (with 1164 practical cases of Mitsubishi PLC)

Still can’t understand electrical diagrams? Take away the basics of electrician diagram reading and simulation software for quick hands-on!

12 free electrician video courses, 10GB of software/eBooks, and 30 days of free live electrician courses are being offered!