Smart Control Education

Focusing on skill training for the smart manufacturing industry

Hello everyone! Learning a small piece of industrial control knowledge every day, I am Xiao Zhi. In order to help everyone standardize the programming methods of PLC controllers for automated equipment, facilitating subsequent maintenance and management of production line equipment, today Xiao Zhi will guide everyone in learning how to connect and communicate touch screens with various PLCs!

Today we will introduce how to connect and communicate touch screens with various PLCs, you can learn together with previous content.

Connecting and Communicating Touch Screens with PLCs

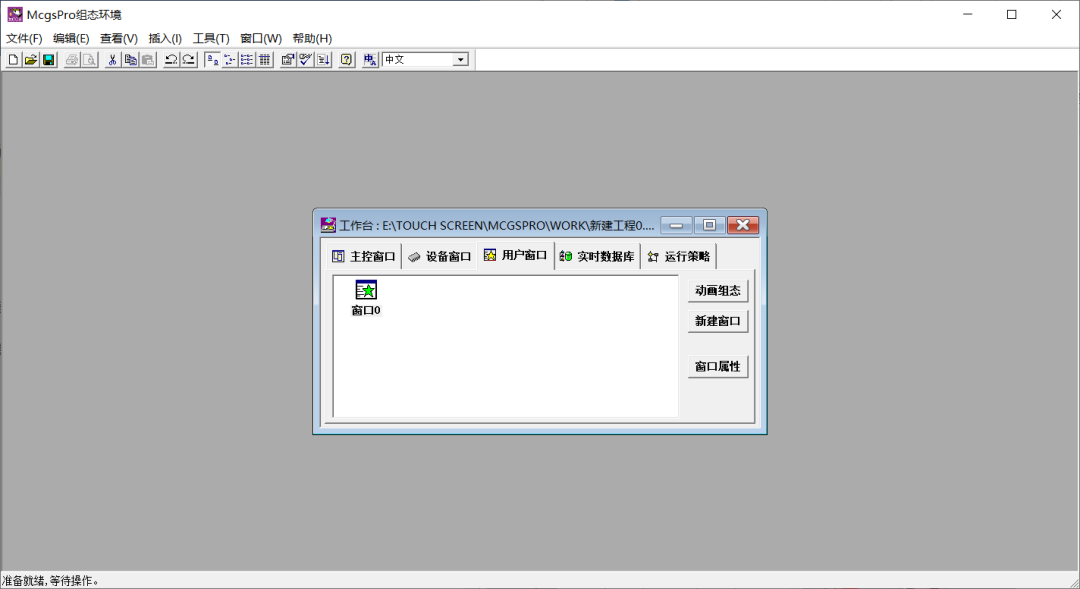

The touchscreen can serve as a status display and input operation for the PLC. MCGSPro is a domestic touchscreen known for its low price and strong applicability. Its basic interface is shown in Figure 1:

First, connect the touchscreen with the Siemens 200smart variables.

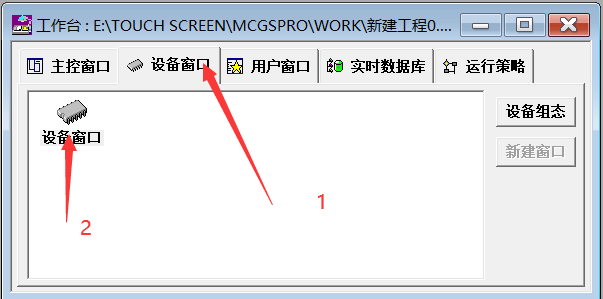

Open the motor device window and double-click to enter the device window as shown in Figure 2:

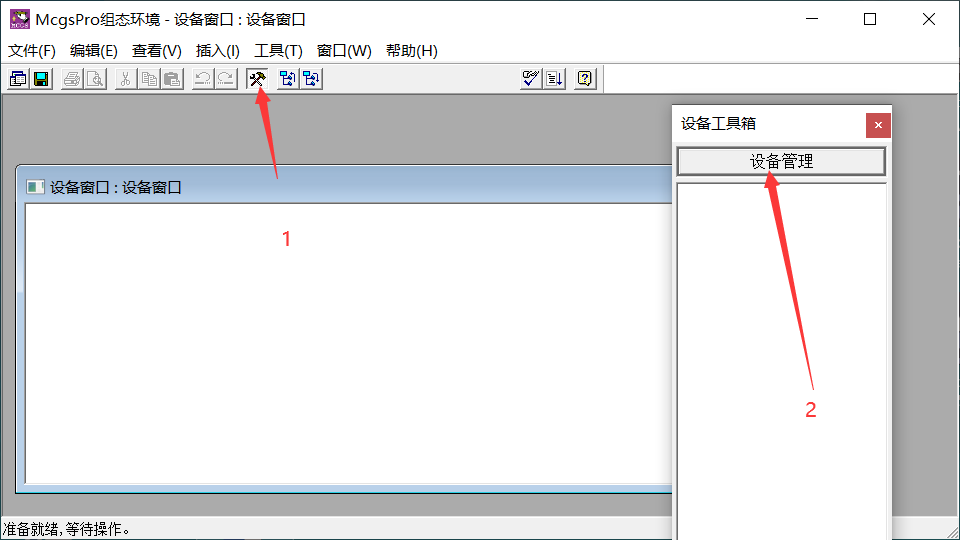

Single machine toolbox, open the device toolbox, and manage motor devices as shown in Figure 3

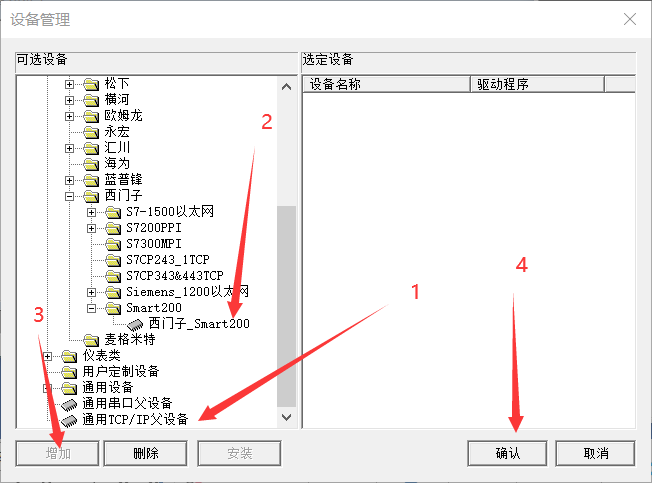

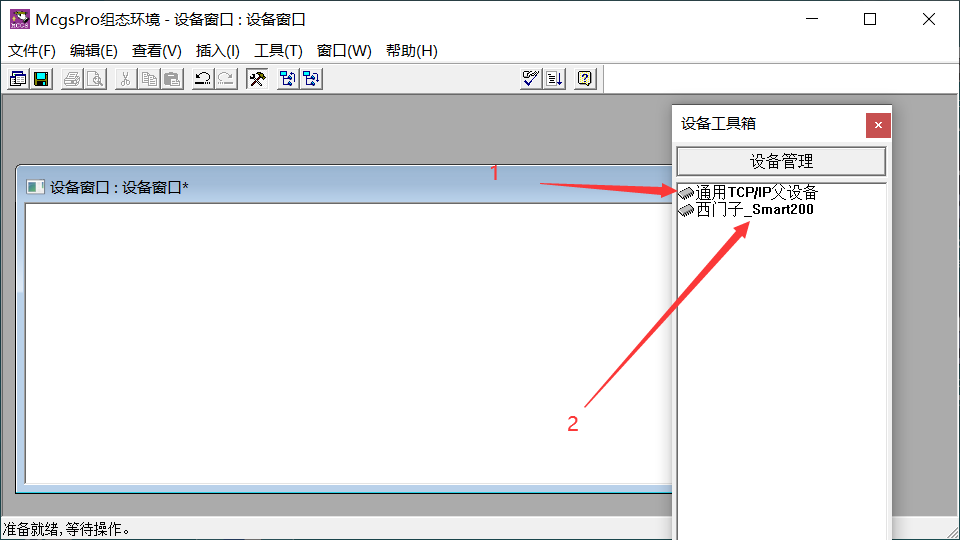

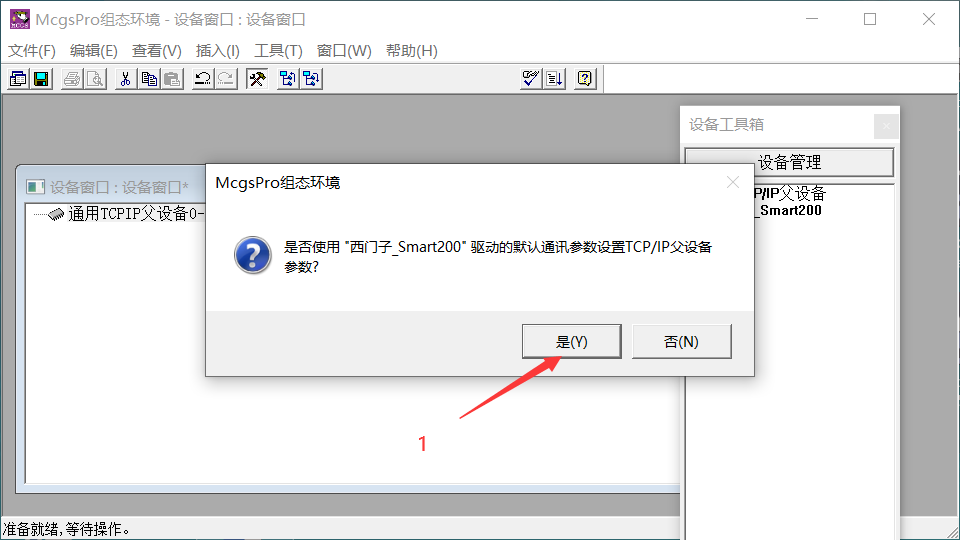

Open all devices – PLC – Siemens – Smart200, click “General TCP/IP Parent Device”, “Siemens_Smart200” respectively, click “Add”, and confirm to add the device as shown in Figures 4 and 5:

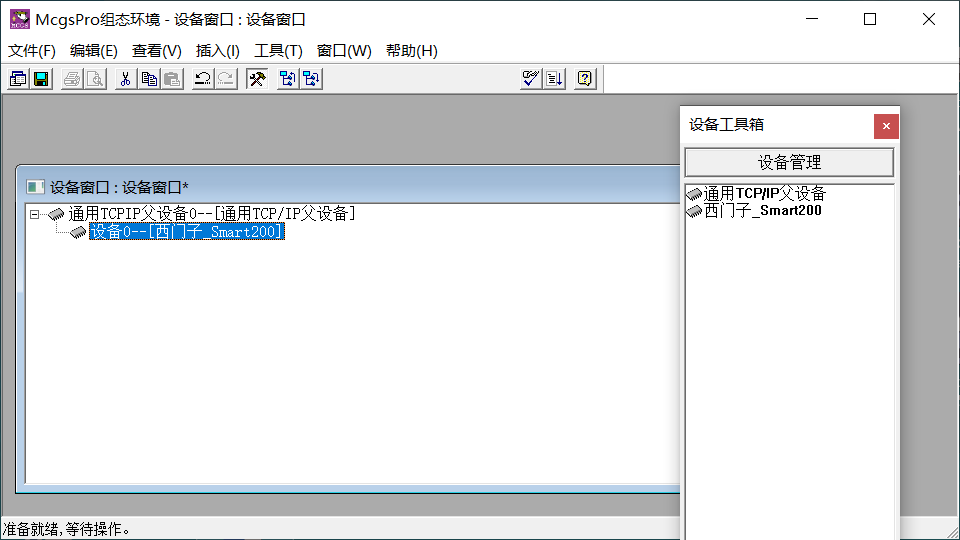

After adding the device, enter the device toolbox as shown in Figure 5, double-click “General TCP/IP Parent Device” and “Siemens_Smart200” to add as shown in Figures 6, 7, and 8.

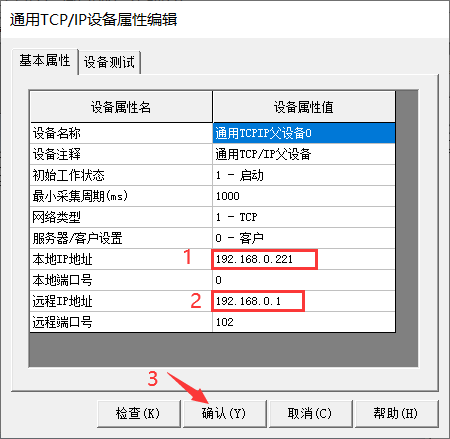

Double-click “Device 0 – [General TCP/IP Parent Device]” to open property editing, set the local IP address to the computer’s IP address (during simulation), and the remote IP address to the PLC’s IP address, thus successfully communicating between the PLC and the touchscreen as shown in Figure 9:

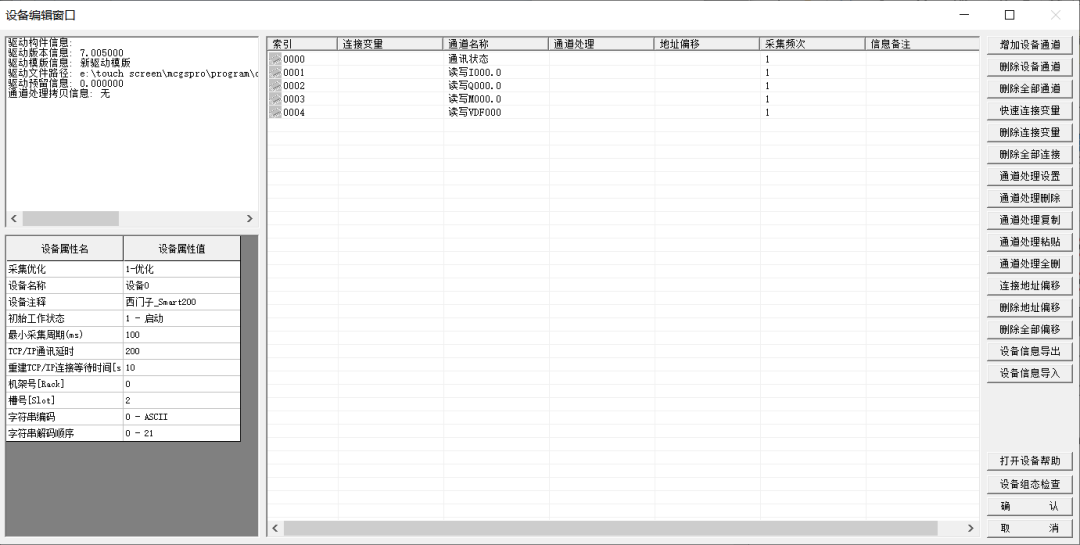

Next, double-click “Device 0 – [Siemens_Smart200]” for variable editing, click “Device Channel”, and add variables such as I, Q, M, V, which correspond to the commonly used IQMV registers of the 200Smart PLC, as shown in Figure 10:

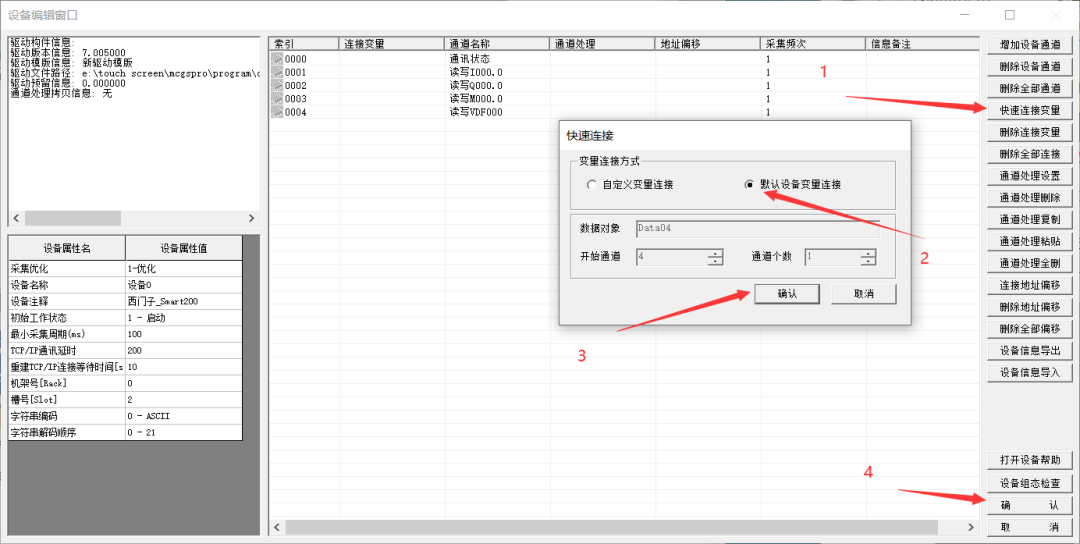

Then click “Quick Connect Variables” – select default device variable connection – “Confirm”, as shown in Figure 11.

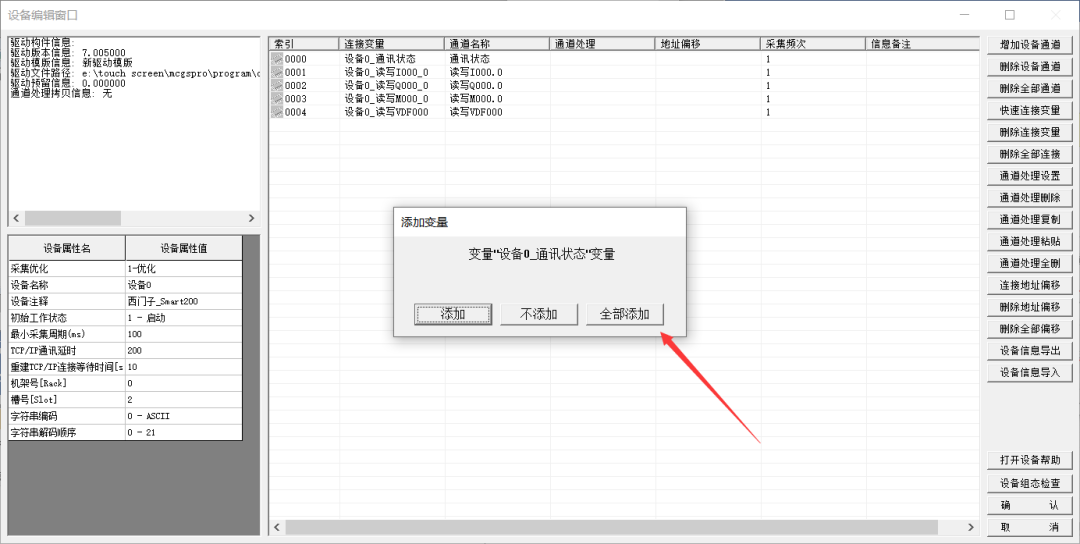

In “Add Variable” click “Add All”, as shown in Figure 12.

At this point, the smart device and touchscreen have successfully communicated, and the variables are successfully connected.

In the next issue, I will continue to introduceconnecting MCGSPro touch screens with PLCs and creating variables. Stay tuned!

Recently, our published articles have been quite substantial, those in need can also refer toprevious recommendations to check them out!

Learning a bit more during the holiday is always worthwhile!

01MCGS Pro Touchscreen Animation Features.

02Here is the Modbus-RTU communication technology you want to know about S7-200smart (1)

03S7-200smart Modbus-RTU Communication V20 (2) Inverter

04Basics of Three-Phase AC Induction Motor Applications

WeChat Official Account: Changzhou Smart Control Education

Click to read the original text for more information

Click to read the original text for more information