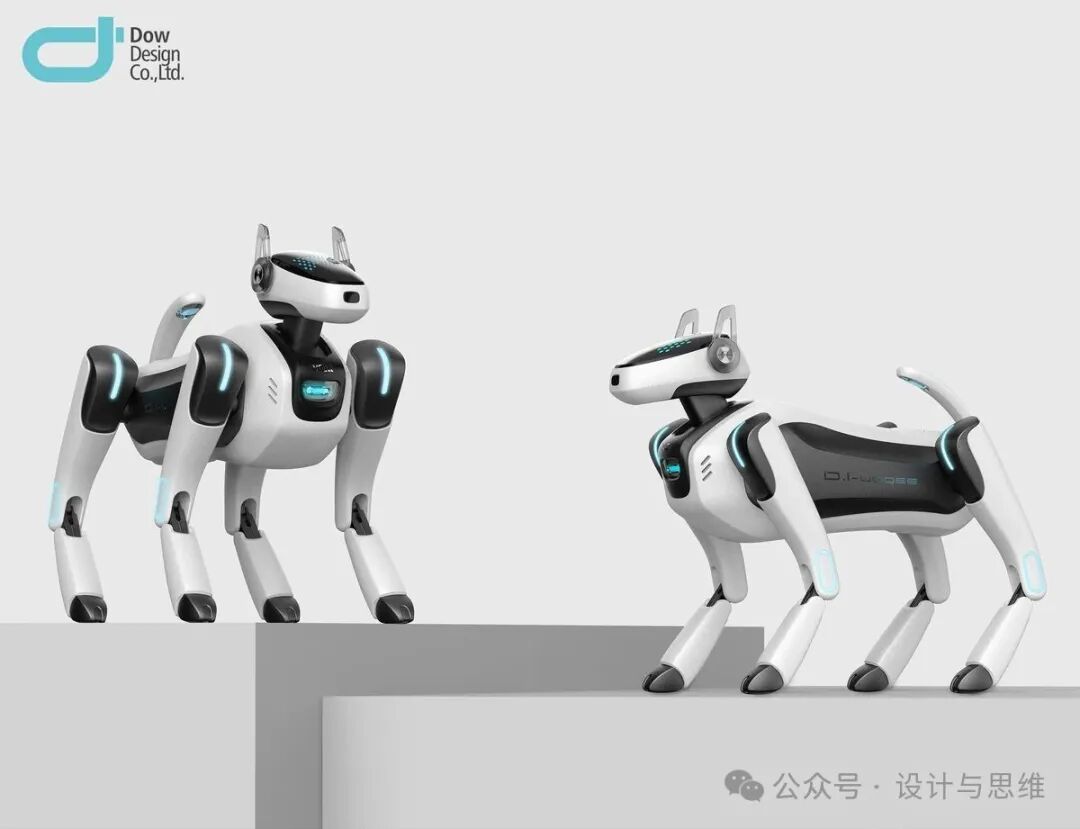

The core of the design of the four-legged robot lies in balancing performance, reliability, cost, maintainability, and usability, making it a practical, deployable, and economically viable tool for addressing specific industrial pain points such as hazardous environment inspections, flexible logistics over large areas, and inspections of unstructured spaces.01

The core of the design of the four-legged robot lies in balancing performance, reliability, cost, maintainability, and usability, making it a practical, deployable, and economically viable tool for addressing specific industrial pain points such as hazardous environment inspections, flexible logistics over large areas, and inspections of unstructured spaces.01

–Core Functionality and Performance Definition–

Mobility and Adaptability This is the core advantage of the four-legged design.The design must ensure excellent passability, stability, and maneuverability (such as turning in place and lateral movement) in typical industrial environments (e.g., uneven ground, stairs, slopes, oil stains, gravel, narrow passages, and confined spaces).Gait algorithms need to be efficient, robust, and energy-controllable.

Payload and Endurance Clearly define the typical and maximum payload required for the target application (e.g., carrying sensors, robotic arms, toolkits, materials).Based on this, design the structural strength, drive system (motors, reducers), and energy system (battery type, capacity, fast charging capability, thermal exchange).Industrial-grade endurance (usually several hours) and quick battery replacement/charging are essential.

Task Execution Capability Is a robotic arm (end effector) integrated?What are the precision, working range, and load capacity?The design must consider the changes in the center of gravity, dynamic effects, and additional power consumption brought by the arm load.

02

-Case Studies-

-Human-Machine Interaction and Operation-

Remote Monitoring and Operation Provide an intuitive remote operation interface that supports status monitoring, manual remote control (for emergencies), task issuance, map editing, etc.

Safety Interaction Mechanism Design clear status indicator lights and sound prompts, with a complete human-machine collision detection and safety stop function (such as emergency stop buttons, software limits, touch edge sensors, force sensing).

Multi-Robot Collaboration Support multiple robots working together (e.g., area division, task relay), requiring efficient communication and scheduling mechanisms.

-Reliability, Maintainability, and Total Cost of Ownership-

High Reliability Design Key components (motors, drivers, batteries, main control) use industrial-grade or even automotive-grade products, undergoing thorough environmental stress screening and life testing.Design fault tolerance mechanisms (e.g., limping ability under single-leg failure).

Maintainability Modular design facilitates quick replacement of faulty components (e.g., single-leg modules, batteries, sensors).Provide diagnostic tools and clear maintenance manuals.Reduce the need for specialized tools.

Repair Costs Reduce the cost and replacement difficulty of key consumables (e.g., foot pads, joint seals).Consider preventive maintenance prompts.

Total Cost of Ownership During the design phase, balance initial procurement costs, operating costs (energy consumption), maintenance costs, and downtime losses.Pursue high reliability and low maintenance costs to reduce TCO.

Image Source: Internet | Do not use for commercial purposes | Contact for removal

Welcome to leave comments and discuss in the comment area~

Highlights Recap

【Design Reference】How to Design a Simple Yet Not Simple Shape? Deeseek Teaches You the Right Solution!【Design Reference】Innovations in Vehicle-Mounted Product Design: How to Create a New Smart Travel Experience?【Design Reference】Product Texture Design: Unique Craftsmanship to Create Distinctive Brand Identity!

【Design Reference】How to Design a Simple Yet Not Simple Shape? Deeseek Teaches You the Right Solution!【Design Reference】Innovations in Vehicle-Mounted Product Design: How to Create a New Smart Travel Experience?【Design Reference】Product Texture Design: Unique Craftsmanship to Create Distinctive Brand Identity!

-Welcome Design Collaboration, Please Leave a Message in the Background-

Exciting Sharing | Cutting-Edge Information | Set as“Starred”!

Welcome to follow, like, and view ↓ ↓ ↓