Distributed hydraulic synchronization system based on PROFIBUS. The system uses PROFIBUS bus communication, employing a combination of fuzzy self-tuning P closed-loop control and feedforward open-loop control methods for variable frequency speed regulation of the motor. It also utilizes configuration software for comprehensive monitoring, enabling continuous adjustment of the hydraulic synchronization system’s cylinder movement. The system is cost-effective, highly automated, offers reliable communication, is fault-diagnosable, has high control precision, and is expandable.

1 Distributed Hydraulic Synchronization Control System

The system employs closed-loop and feedforward variable frequency speed control to achieve continuous control of the synchronized movement displacement of each cylinder. This is primarily done by real-time monitoring of displacement signals using high-precision displacement sensors, and closed-loop control is performed through fuzzy self-tuning P control and feedforward control algorithms. The inverter adjusts the speed of the three-phase AC asynchronous motor, allowing for continuous adjustment of the hydraulic pump flow rate. Simultaneously, configuration software is used for real-time monitoring of data and status, alarms, fault storage, and query functions.

1) Overall Structural Principle

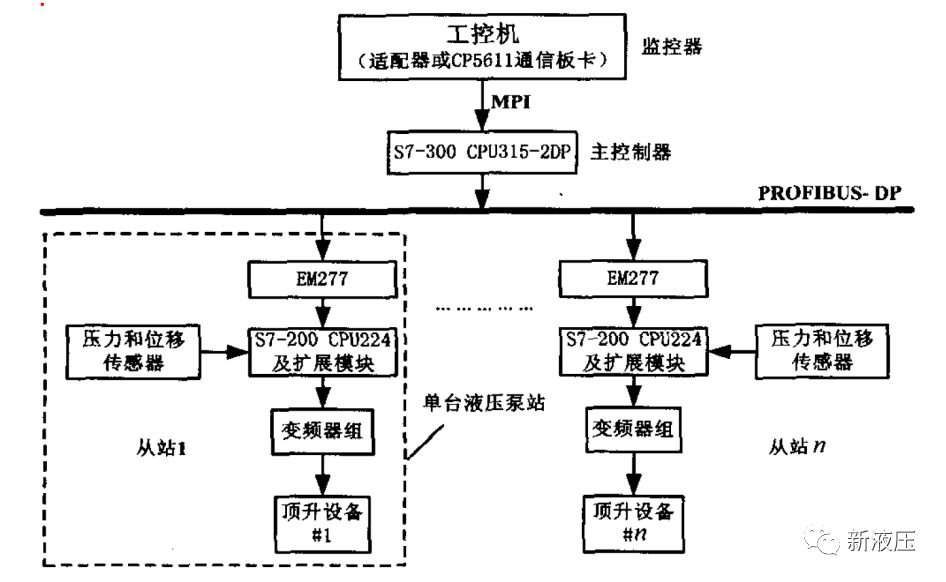

The overall structure of the distributed hydraulic synchronization control system is shown in Figure 28.

Figure 28 Overall Design Structure Block Diagram

The industrial control computer communicates with the main control system via the MPI adapter or CP5611 communication card, primarily for monitoring system information, alarms, fault diagnosis, and control through the developed configuration software KingView. The main control system consists of the controller $7300 and its I/O expansion modules, serving as the master station. A single hydraulic pump station consists of the controller S7200, sensors, and hydraulic equipment, acting as the slave station. The system design of a single hydraulic pump station is shown in Figure29. A hydraulic pump station is generally designed as a four-point control system. Information transmission between the main control system and each hydraulic pump station is completed via the PROFIBUS high-speed industrial bus. Due to the special characteristics of the PROFIBUS high-speed industrial bus, the number of communication and control signal lines in the entire control system is significantly reduced, while improving the control performance and reliability of the system.

Note: Please contact the author for authorization to reprint. Author: Professor Huang Zhijian, Guangzhou New Europe Machinery Co., Ltd., 020-82333916