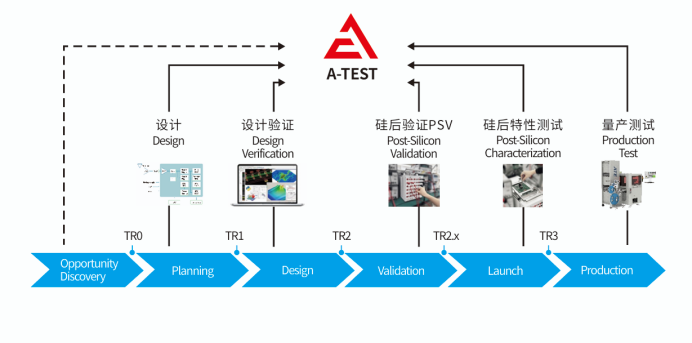

In the complex journey of chip development, Post-Silicon Validation (PSV) plays a crucial role. Once the chip transitions from design blueprints to actual silicon wafers, PSV becomes the core process to verify whether it meets the expected functionality and performance.

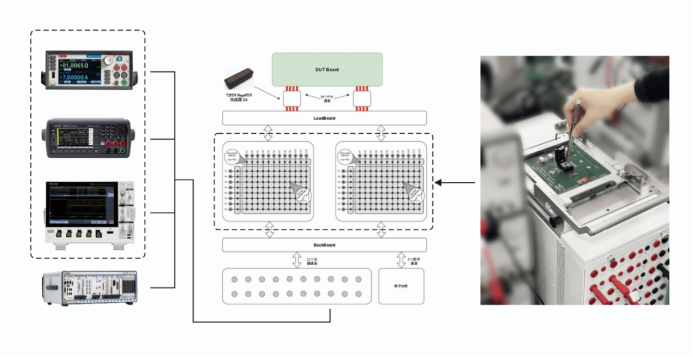

From a technical perspective, PSV primarily involves inputting various test vectors into the chip to simulate different signal combinations in real working scenarios, followed by a detailed observation of the chip’s output responses. This process assesses whether the internal circuit logic, signal integrity, and electrical performance of the chip meet the standards. For instance, in logical function verification, a series of complex arithmetic operations are tested on the chip’s Arithmetic Logic Unit (ALU) to check if the results align with theoretical values; regarding signal integrity, attention is paid to whether high-speed signals experience distortion or abnormal delays during internal transmission.

In the field of PSV, common technical methods include hardware accelerator-based testing, machine learning-based defect prediction, and Built-In Self-Test (BIST) technology applications. Hardware accelerator-based testing can significantly enhance testing speed and shorten testing cycles; machine learning-based defect prediction can foresee potential issues early, improving testing efficiency; BIST technology enhances the chip’s self-testing capabilities, reducing reliance on external testing equipment.

The PSV testing system launched by Anke has unique advantages in the industry. This system is rooted in Anke’s 20 years of profound experience in the design of chip testing platform hardware and software systems, deeply integrating automated testing concepts throughout the entire lifecycle of chip development from design to mass production. It features a fully automated PSV operation process, greatly enhancing testing efficiency, achieving several times the efficiency compared to traditional testing methods, and effectively compressing product time-to-market. The system offers excellent flexibility in instrument expansion, allowing easy addition or replacement of instruments based on different chip testing needs, adeptly handling diverse testing tasks. The automatic test report generation function presents test results in a standardized and efficient manner, coupled with powerful test data analysis capabilities that can deeply mine data value, assisting R&D personnel in accurately locating issues. It closely aligns with the TestPlan editing and debugging habits of chip manufacturers, reducing the learning curve for operators and ensuring the accuracy of test plan formulation and execution.

In terms of chip model switching, the system performs excellently, enabling quick transitions, and the measurement process employs graphical displays, making the chip performance status clear at a glance for testers. Additionally, the universal Driver PIN design and rapid DUT Board design capabilities significantly shorten testing preparation time and reduce testing costs, providing an efficient and reliable PSV testing solution for Fabless and IDM companies, helping them gain a competitive edge in the fierce market.

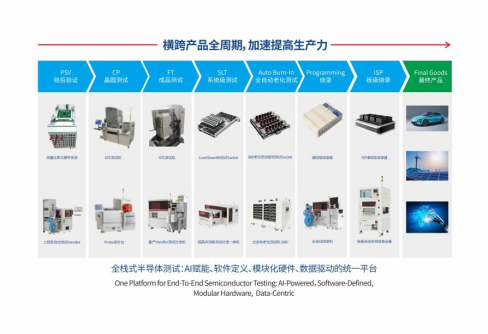

We provide customers with equipment products and solutions covering all stages of PSV post-silicon validation, CP wafer testing, FT finished product testing, SLT system-level testing, BI aging testing, and programming, integrating the entire testing process into a one-stop service. This helps customers efficiently complete the entire cycle of quality control from chip validation to product delivery, simplifying processes while enhancing testing efficiency and reliability.

About Anke Technology

Anke Technology, established in 2013, is a global leader in fully automated programming/testing solutions for semiconductor chips. The company has served many well-known enterprises in the industry, including Huawei, Infineon, Microchip, BYD, and Foxconn. Anke’s semiconductor testing R&D team is led by top technical experts from Fairchild Semiconductor, Texas Instruments, Freescale, and Microchip, gathering elite talents from mainland China, Taiwan, Japan, and Singapore, combining advanced semiconductor testing technology with ultra-high precision semiconductor chip sorting technology, integrating unique AI algorithm optimization strategies and system intelligent customization solutions. Anke’s V9000 series testing and sorting machines can be applied to Burn-In reliability testing for products requiring high reliability, such as power modules, AI large model training chip SOCs, GPUs, CPUs, and automotive-grade intelligent driving SOCs, as well as system-level testing for various SOCs and large-capacity storage chips (eMMC, UFS, LPDDR, etc.), RF chips, and modules. The company also provides SLT testing and sorting machines, translational P&P sorting machines, turret sorting machines, and IC laser marking machines, among other series of post-processing testing and sorting equipment.

Scan to follow us

Anke Semiconductor Testing Service Account

Anke Semiconductor Testing Subscription Account