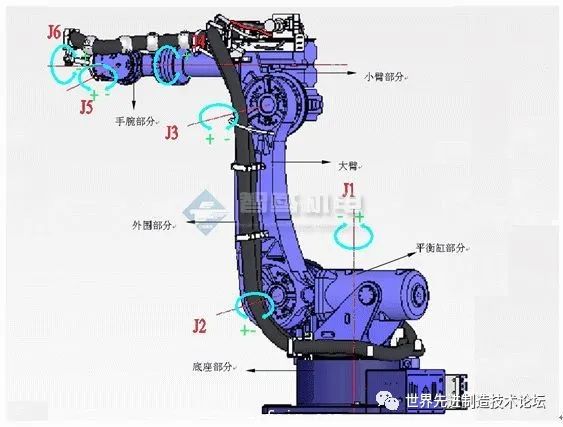

1. Main Body

The main body of the robot consists of the base and execution mechanism, including the upper arm, lower arm, wrist, and hand, forming a multi-degree-of-freedom mechanical system. Some robots also have walking mechanisms. Industrial robots typically have 6 degrees of freedom or even more, with the wrist usually having 1 to 3 degrees of active freedom.

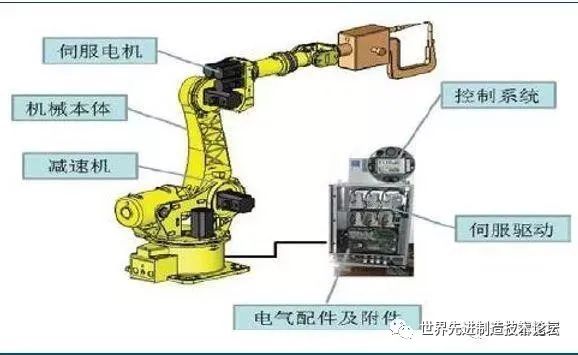

2. Drive System

The drive system of industrial robots can be classified into three main types based on power source: hydraulic, pneumatic, and electric. Depending on the requirements, these three types can also be combined into a composite drive system. Alternatively, indirect drive can be achieved through mechanical transmission mechanisms such as synchronous belts, gear trains, and gears. The drive system includes power devices and transmission mechanisms to execute corresponding actions in the execution mechanism. Each of these three fundamental drive systems has its characteristics, with electric drive systems being the mainstream today.

Due to low inertia and high torque, the widespread adoption of AC and DC servo motors and their matching servo drivers (frequency converters, DC pulse width modulators) has occurred. This type of system does not require energy conversion, is easy to use, and offers sensitive control. Most motors need to be equipped with precise transmission mechanisms: gear reducers. Their gears use gear speed converters to reduce the motor’s rotation speed to the desired level while obtaining greater torque. Increasing the power of the servo motor is not cost-effective when the load is heavy; it is more efficient to improve output torque through reducers within suitable speed ranges. Servo motors can easily overheat and experience low-frequency vibrations during low-frequency operations, making prolonged and repetitive work detrimental to their accuracy and reliability. The existence of precision gear motors allows servo motors to operate at suitable speeds, enhancing the rigidity of the machine while outputting greater torque. Currently, the mainstream reducers are of two types: harmonic reducers and RV reducers.

3. Control System

The robot control system is the brain of the robot, determining its functions and capabilities. The control system issues command signals to the drive system and execution mechanism based on the input program and manages the control. The primary task of industrial robot control technology is to control the robot’s working space, posture, trajectory, and timing of actions. It features simple programming, software menu manipulation, a user-friendly human-computer interaction interface, online manipulation prompts, and ease of use.

The controller system is the core of the robot, and foreign companies have been conducting tight experiments in China. In recent years, with the development of microelectronics technology, microprocessors have become increasingly powerful and cheaper, with 32-bit microprocessors now available on the market for 1-2 US dollars. The cost-effective microprocessor has brought new development opportunities for robot controllers, making it possible to develop low-cost, high-performance robot controllers. To ensure sufficient computing and storage capabilities, most robot controllers now adopt strong chips from the ARM series, DSP series, POWERPC series, Intel series, etc.

Existing general-purpose chip functions and capabilities cannot fully meet the requirements of some robot systems in terms of price, performance, integration, and interfaces. This has led to the demand for SoC (System on Chip) technology in robot systems, which integrates specific processors with required interfaces, simplifying the design of peripheral circuits and reducing system size and costs. For instance, Actel integrates NEOS or ARM7 processor cores into its FPGA products, forming a complete SoC system. Research on robot technology controllers mainly focuses on the United States and Japan, with mature products available, such as those from DELTATAU in the United States and POMT in Japan. Their motion controllers are based on DSP technology and adopt an open structure based on PC.

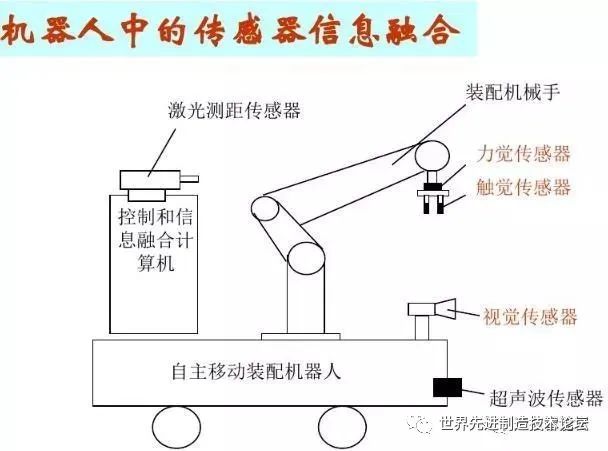

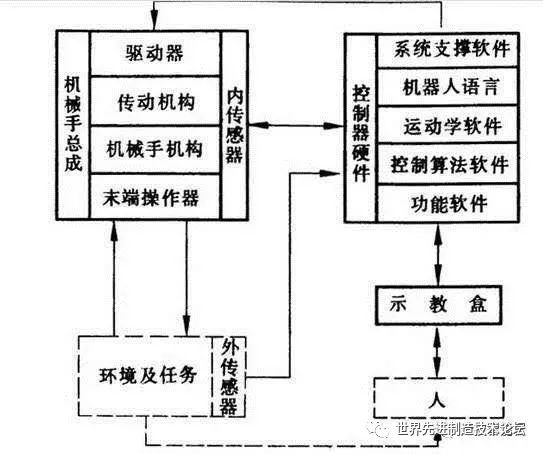

4. Perception System

It consists of internal sensor modules and external sensor modules, obtaining meaningful information about the internal and external environmental states.

Internal Sensors: Sensors used to detect the robot’s own state (e.g., angles between arms), mostly position and angle sensors. Specific types include position sensors, angle sensors, etc.

External Sensors: Sensors used to detect the robot’s environment (e.g., detecting objects, distance to objects) and conditions (e.g., detecting whether grasped objects are slipping). Specific types include distance sensors, vision sensors, force sensors, etc.

The use of intelligent sensing systems enhances the robot’s mobility, practicality, and intelligence standards. The human perception system is agile in obtaining information about the external world, while sensors can be more effective than human systems for specific information.

5. End Effector

The end effector is a component connected to the last joint of the robotic arm, typically used for grasping objects, connecting to other mechanisms, and executing required tasks. Robot manufacturers generally do not design or sell end effectors; in most cases, they only provide a simple gripper. Typically, the end effector is mounted on the flange of the robot’s 6-axis to complete tasks in a given environment, such as welding, painting, gluing, and loading/unloading parts, which are tasks that require robots to accomplish.

Overview of Servo Motors

Servo drivers, also known as “servo controllers” or “servo amplifiers,” are controllers used to control servo motors, functioning similarly to frequency converters for standard AC motors and are part of the servo system. They generally control servo motors through position, speed, and torque to achieve high-precision positioning of the drive system.

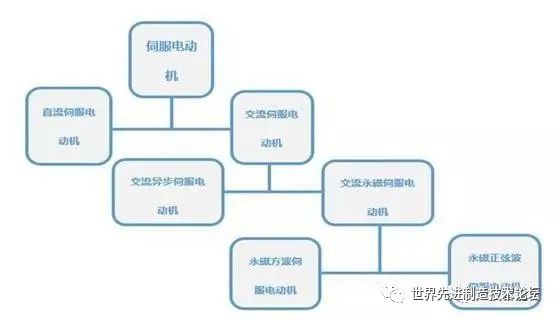

1. Classification of Servo Motors

They are divided into two main categories: DC and AC servo motors. AC servo motors are further divided into asynchronous servo motors and synchronous servo motors, with AC systems gradually replacing DC systems. Compared to DC systems, AC servo motors offer advantages such as high reliability, good heat dissipation, low inertia, and the ability to operate under high-voltage conditions. Due to the absence of brushes and commutators, AC servo systems are also referred to as brushless servo systems, using brushless structures such as cage asynchronous motors and permanent magnet synchronous motors.

1) DC servo motors are divided into brushed and brushless motors

① Brushed motors have low costs, simple structures, high starting torque, wide speed ranges, and easy control, but require maintenance (changing brushes) and generate electromagnetic interference, thus having specific environmental requirements. They are usually used in cost-sensitive general industrial and civilian applications;

② Brushless motors are small in size and weight, provide high output, quick response, high speed, low inertia, stable torque, and smooth rotation. They are complex to control, intelligent, and flexible in electronic commutation methods, capable of using square wave or sine wave commutation. These motors are maintenance-free, energy-efficient, have low electromagnetic radiation, low temperature rise, and long lifespans, making them suitable for various environments.

2. Characteristics of Different Types of Servo Motors

1) Advantages and Disadvantages of DC Servo Motors

Advantages: Precise speed control, rigid torque-speed characteristics, simple control principles, ease of use, and low cost.

Disadvantages: Brush commutation, speed limitations, additional resistance, and wear particle generation (not suitable for dust-free or explosive environments).

2) Advantages and Disadvantages of AC Servo Motors

Advantages: Good speed control characteristics, smooth control across the entire speed range, almost no oscillation, over 90% high efficiency, low heat generation, high-speed control, and high-precision position control (dependent on encoder precision). Within the rated operating area, they can achieve constant torque, low inertia, low noise, no brush wear, and are maintenance-free (suitable for dust-free and explosive environments).

Disadvantages: More complex control, drive parameters need to be adjusted on-site to determine PID parameters, and require more wiring.

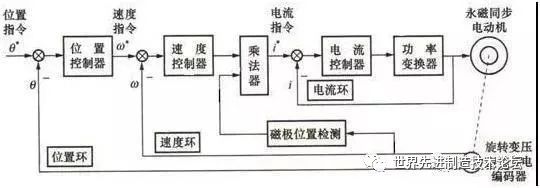

Currently, mainstream servo drivers use digital signal processors (DSP) as the control core, enabling the implementation of relatively complex control algorithms and achieving digitization, networking, and intelligence. The power devices commonly use drive circuits designed around intelligent power modules (IPM), which integrate driving circuits and have fault detection protection circuits for overvoltage, overcurrent, overheating, and undervoltage. Soft-start circuits are also added to the main circuit to reduce the impact on drivers during the starting process. The power drive unit first rectifies the input three-phase power or mains power through a three-phase full-bridge rectifier circuit to obtain the corresponding DC power. The rectified three-phase power or mains power is then converted through a three-phase sine PWM voltage inverter to drive the three-phase permanent magnet synchronous AC servo motor. The entire process of the power drive unit can be simply described as AC-DC-AC. The main topology circuit of the rectifier unit (AC-DC) is a three-phase full-bridge uncontrolled rectifier circuit.

3. Wiring Diagram of the Servo System

1. Driver Wiring

The servo driver mainly includes control loop power, main control loop power, servo output power, controller input CN1, encoder interface CN2, and connection port CN3. The control loop power is a single-phase AC power supply, and the input power can be single-phase or three-phase, but it must be 220V. This means that when using three-phase input, our three-phase power must be transformed to connect. For smaller power drivers, single-phase direct driving is possible, and the single-phase connection must connect to R, S terminals. The servo motor outputs U, V, W must not be connected to the main circuit power, as this may burn out the driver. The CN1 port is mainly used for connecting the upper-level controller, providing input, output, encoder ABZ three-phase output, and various monitoring signal analog outputs.

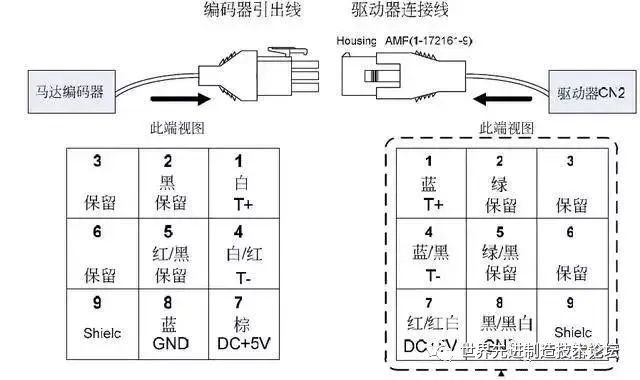

2. Encoder Wiring

From the above diagram, we see that out of nine terminals, we only use five: one shielded wire, two power wires, and two serial communication signals (+-), similar to our ordinary encoder wiring.

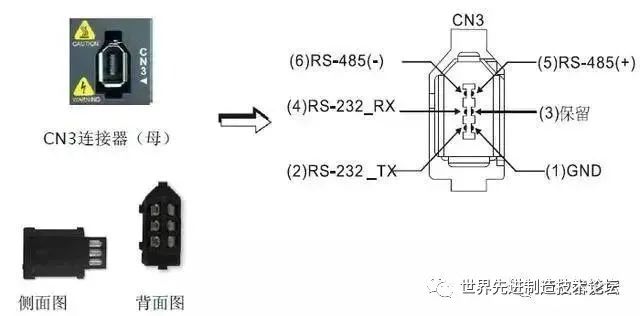

3. Communication Port

The driver connects to the computer PLC, HMI, and other upper-level machines through the CN3 port, using MODBUS communication to control the driver, which can use RS232 or RS485 for communication.

4. Servo Driver Market

Robots have strict requirements for joint drive motors, and AC servo motors are widely used in industrial robots. Currently, the high-end domestic market is mainly occupied by foreign brands, mainly from Japan and Europe and the United States, with significant potential for domestic replacement in the future. Currently, foreign brands hold nearly 80% of the Chinese AC servo market, mainly from Japan and Europe and the United States. Among them, Japanese products occupy the top position with about 50% market share, with famous brands including Panasonic, Mitsubishi Electric, Yaskawa, Sanyo, Fuji, etc. Their products meet the needs of Chinese users in terms of technology and performance, achieving stable and continuous customer sources with good cost-effectiveness and high reliability, particularly dominating the small and medium-sized OEM market.

Precision Reducers

Recently, I saw a news article stating that the robot industry must overcome the “bottleneck” problem, which resonated with me. With rising labor costs, replacing humans with industrial robots has become a trend. Industrial robots are the cornerstone of intelligent manufacturing, but core components restrict the development of China’s robot industry. According to relevant surveys, domestic robot reducers are generally dependent on imports. To develop the robot industry in China, we must decisively address the issues surrounding core components.

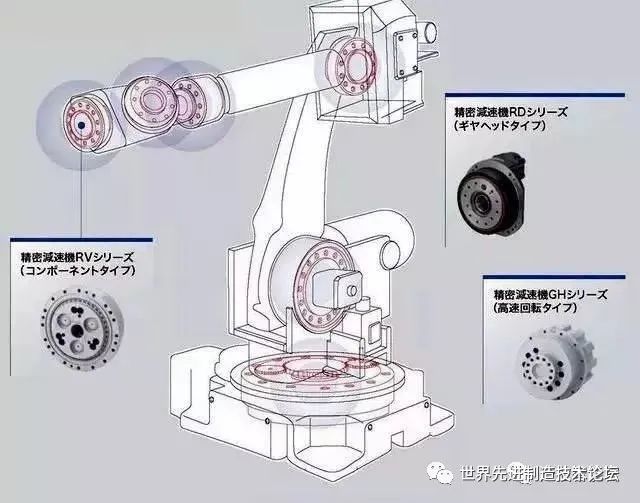

Below is an introduction to the core precision components of industrial robots: reducers. Compared to general reducers, robot reducers are required to have characteristics such as a short transmission chain, small size, high power, light weight, and ease of control. In the reducer industry, we must mention two giants: Nabtesco and Hamonica Drive, commonly referred to as RV reducers and harmonic reducers. They nearly monopolize the global market for robot reducers. Both types of reducers have micron-level processing accuracy, and achieving high reliability during mass production is challenging, not to mention high-speed operation at thousands of revolutions while maintaining long lifespans. Currently, the reducers widely used in industrial robots mainly fall into two categories: RV reducers and harmonic reducers.

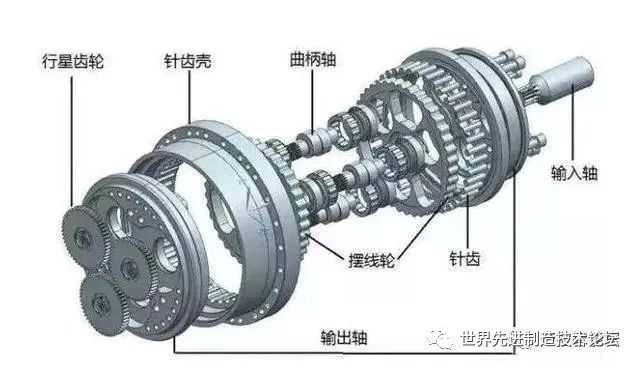

RV Reducers: These use low-tooth difference meshing, but compared to harmonic reducers, RV reducers typically use cycloidal pin gears, consisting of cycloidal pin gears and planetary brackets. The key to RV reducers lies in their processing and assembly technology, offering higher fatigue strength, stiffness, and lifespan compared to harmonic drives, which significantly reduce motion accuracy over time. Their disadvantage is that they are heavier and bulkier. RV reducers are used in the joints of robots with high torque requirements, such as the legs, waist, and elbows, and are used for the first three axes of heavy industrial robots.

They have much higher fatigue strength, stiffness, and lifespan than the commonly used harmonic drives in robots, and their backlash accuracy is stable, unlike harmonic drives, which suffer significant motion accuracy degradation over time. Therefore, many countries worldwide prefer RV reducers for high-precision robotic drives, and RV reducers are gradually replacing harmonic reducers in advanced robotic transmissions.

RV Reducer Disassembly Diagram

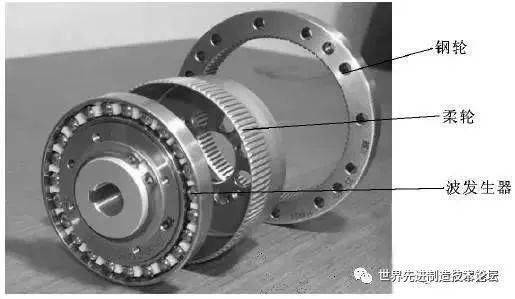

Harmonic Reducers: These also use low-tooth difference meshing, and a key gear in harmonic drives is flexible, requiring repeated high-speed deformation, making it relatively fragile with limited load capacity and lifespan.

Harmonic reducers are a type of harmonic drive system, which includes harmonic accelerators and harmonic reducers. A harmonic reducer mainly comprises a rigid wheel, flexible wheel, and a wave generator that undergoes radial deformation. It utilizes flexible gears to create controllable elastic deformation waves, causing the rigid and flexible wheels to misalign their teeth to transmit power and motion. This transmission method is fundamentally different from conventional gear transmissions, featuring special considerations in meshing theory, assembly calculation, and structural design. Harmonic gear reducers have advantages such as high precision and high load capacity. Compared to ordinary reducers, they use 50% less material, reducing their size and weight by at least one-third. Therefore, harmonic reducers are mainly used in small robots, characterized by small size, lightweight, high load capacity, and high motion precision, with large single-stage transmission ratios. They are generally used in small-load industrial robots or the end axes of large robots.

Harmonic Reducer Disassembly Diagram

Japan’s Nabtesco company made substantial breakthroughs in RV design from the early 1980s to 1986, taking 6-7 years; meanwhile, domestic companies like Nantong Zhenkang and Hengfengtai also spent 6-8 years achieving results. Does this mean that local companies have no opportunities? Fortunately, Chinese companies have made some breakthroughs after several years of layout. Major domestic producers include Nantong Zhenkang, Qin Chuan Machine Tool, Wuhan Jinghua, Zhejiang Hengfengtai, and Zhejiang Shuanghuan Drive. It is said that Nantong Zhenkang’s output has surpassed ten thousand units, and Qin Chuan Machine Tool’s production line is gradually ramping up. Qin Chuan Machine Tool’s project is a national import replacement initiative, with a total investment of 314 million yuan for its industrial robot joint reducer technology transformation project and production line.

Control System

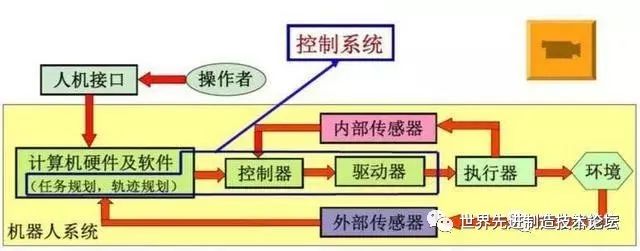

The robot control system is the brain of the robot, determining its functions and capabilities. The control system issues command signals to the drive system and execution mechanism based on the input program and manages the control. The following article mainly introduces the robot control system.

1. Robot Control System

The purpose of “control” is to ensure that the controlled object behaves as expected. The basic condition for “control” is to understand the characteristics of the controlled object.

The essence is the control of the torque output of the driver. The robot’s control system

2. Basic Working Principle of Robots

The working principle is teaching and reproducing; teaching, also known as guided teaching, involves manually guiding the robot through the required action process step by step. During the guiding process, the robot automatically memorizes each action’s posture, position, process parameters, and motion parameters, generating a continuous execution program. After teaching, giving the robot a start command will allow it to automatically complete the entire process according to the taught actions.

3. Classification of Robot Control

1) Divided into open-loop control and closed-loop control based on feedback

Open-loop precise control conditions: precisely knowing the model of the controlled object and maintaining this model unchanged during control.

2) Divided into force control, position control, and mixed control based on the expected control quantity.

Position control is divided into: single-joint position control (position feedback, position-speed feedback, position-speed-acceleration feedback), multi-joint position control.

Multi-joint position control is divided into decomposed motion control and centralized control; force control is divided into: direct force control, impedance control, and force-position mixed control.

3) Intelligent control methods

Fuzzy control, adaptive control, optimal control, neural network control, fuzzy neural network control, expert control.

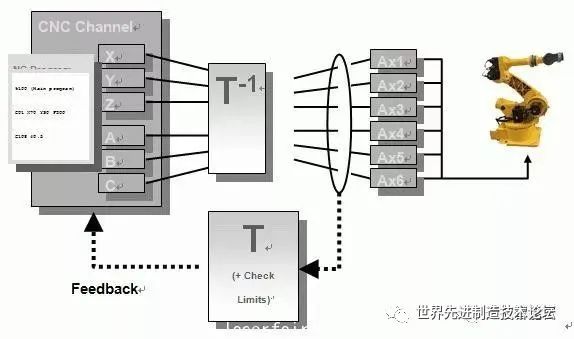

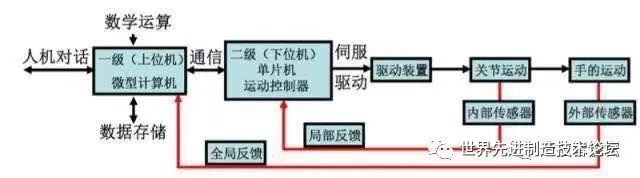

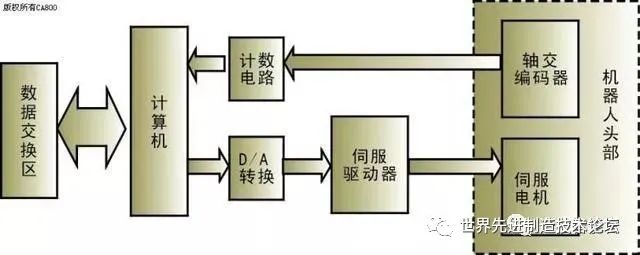

4. Hardware Configuration and Structure of the Control System .Electrical Hardware .Software Architecture

Due to the involvement of numerous coordinate transformations and interpolation calculations, as well as low-level real-time control in the robot’s control process, most robot control systems on the market adopt a layered structure using microcomputer control systems, typically employing a two-level computer servo control system.

1) Specific Process:

The main control computer receives the job instructions input by the staff, first analyzes and interprets the instructions, and determines the motion parameters of the hand. Then, kinematics, dynamics, and interpolation calculations are performed to derive the coordinated motion parameters for each joint of the robot. These parameters are output to the servo control level via communication lines as the set signals for each joint’s servo control system. The servo drivers on the joints convert this signal from D/A to drive each joint to produce coordinated motion.

Sensors feed back the motion output signals of each joint to the servo control level computer, forming a local closed-loop control to achieve precise control of the robot’s motion in space.

2) Motion Control Based on PLC – Two Control Methods:

① Using the output ports of the PLC to generate pulse instructions to drive the motor while using general I/O or counting components to achieve closed-loop position control of the servo motor.

② Using external position control modules to achieve closed-loop position control of the motor. This method mainly generates high-speed pulses for control, belonging to position control methods, which are mostly point-to-point position control.

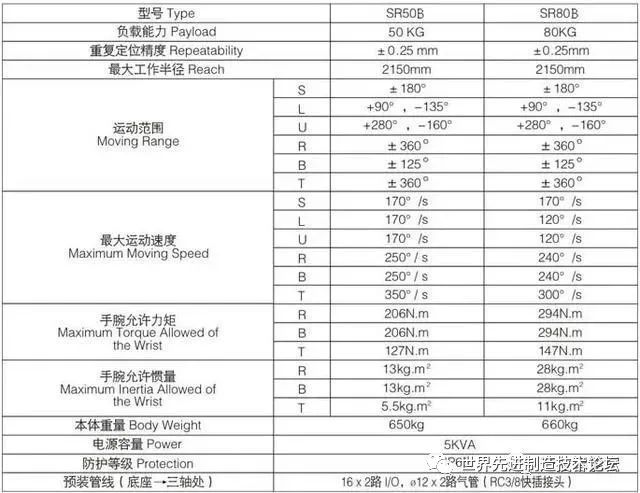

Important Parameters of Robots

This article focuses on the technical parameters of industrial robots, with detailed illustrations and descriptions, hoping to be helpful to everyone!

The technical parameters of robots reflect the work they can perform and their highest operational performance, which are essential considerations in designing and applying robots. The main technical parameters of robots include degrees of freedom, resolution, working space, working speed, and working load.

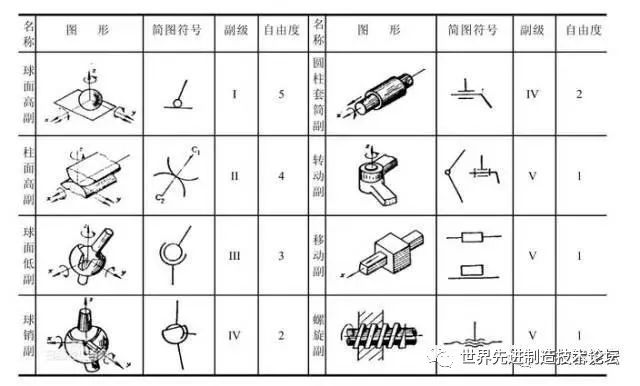

1. Degrees of Freedom

This refers to the number of independent motion axes the robot has.

The degrees of freedom of the robot refer to the number of independent motion parameters required to determine the position and posture of the robot’s hand in space. The number of degrees of freedom generally equals the number of joints.

Common robots typically have 5 to 6 degrees of freedom. Some robots also have external axes.

2. Joint

Also known as a motion pair, it allows relative motion between the components of the robot’s arm.

3. Working Range

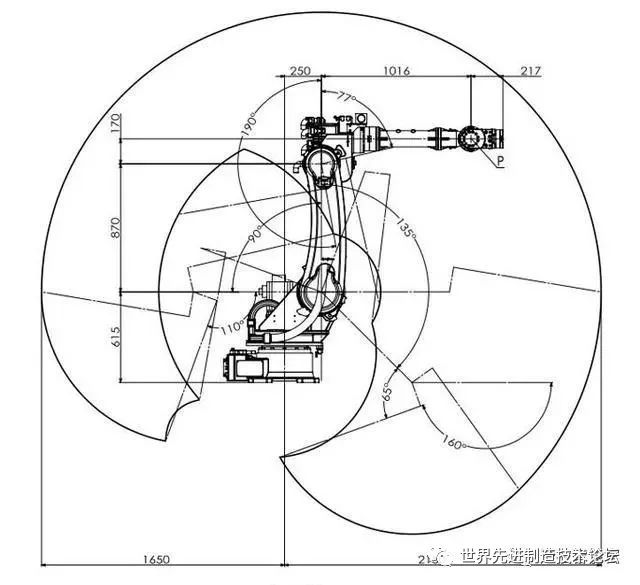

This refers to the entire spatial range that the robotic arm or hand mounting point can reach.

The shape of the working range depends on the number of degrees of freedom and the types and configurations of each motion joint. The working range of robots can generally be represented using graphical or analytical methods.

4. Speed

This refers to the distance moved or angle rotated by the center of the mechanical interface or tool center point within a unit time during uniform motion under load.

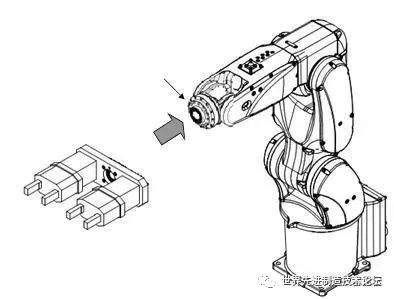

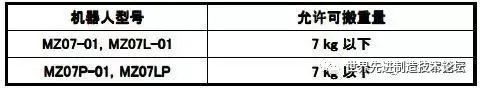

5. Working Load

This refers to the maximum weight that the load installed at the front end of the robot’s wrist can bear at any position within the working range, generally expressed in terms of mass, torque, and inertia. It is also related to parameters such as operating speed and acceleration. The working load is generally indicated by the weight of the workpiece that the robot can grasp during high-speed operation.

For handling robots, the total weight of the gripper and workpiece must be considered.

6. Resolution

This refers to the minimum movement distance or minimum rotation angle that the robot can achieve.

7. Accuracy

Repeatability or repeat positioning accuracy: This refers to the difference in reaching a specific target position multiple times. For example, if you require an axis to move 100 mm and it actually moved 100.01 mm the first time, and then moved 99.99 mm during a repeated action, the difference of 0.02 mm is the repeat positioning accuracy. It measures the concentration of a set of error values, indicating repeatability. The accuracy of the robot is not only determined by the joint reducers and transmission devices but also significantly related to mechanical assembly processes, as many inaccuracies in assembly lead to reduced repeat positioning accuracy.

Disclaimer: This article is a network reprint, and the copyright belongs to the original author. However, due to numerous reprints, it is impossible to confirm the true original author, so only the source of reprint is indicated. If the videos, images, and texts used in this article involve copyright issues, please inform us immediately, and we will confirm the copyright based on the proof materials you provide and pay remuneration according to national standards or delete the content immediately! The content of this article reflects the original author’s views and does not represent the stance of this public account or its authenticity.