If you are interested in this report, please contact Engineer Fu at 15210591823, add WeChat “FuZoomWin”, or follow our official Bilibili account “Zhongfei Power”..

Part 01 Introduction

First, let’s introduce DJI’s in-vehicle business.

Shenzhen Zhuoyu Technology was initially launched in 2016 as an internal project of DJI, focusing on the research and development of autonomous driving technology. After years of development, DJI’s autonomous driving business was spun off as an independent company in 2023 for external financing, and after two rounds of financing, its valuation has reached 1.5 billion USD.

The company is committed to the research, manufacturing, and sales of intelligent driving systems and their core components. The goal is to achieve positive financial indicators by 2024.

The number of employees has grown from fewer than 10 to nearly 1,000, demonstrating the company’s rapid expansion and business growth.

Zhuoyu’s main products include intelligent driving solutions and smart components. Intelligent driving solutions cover L2+ to L3 level autonomous driving technology, including but not limited to intelligent driving D80/D80+, D130/D130+, intelligent parking P100/P1000, etc.

The “Chengxing” platform is Zhuoyu’s new generation intelligent driving solution. Its features include low computing power, pure visual configuration, not relying on high-precision maps or lidar, achieving urban memory driving and urban leading driving functions.

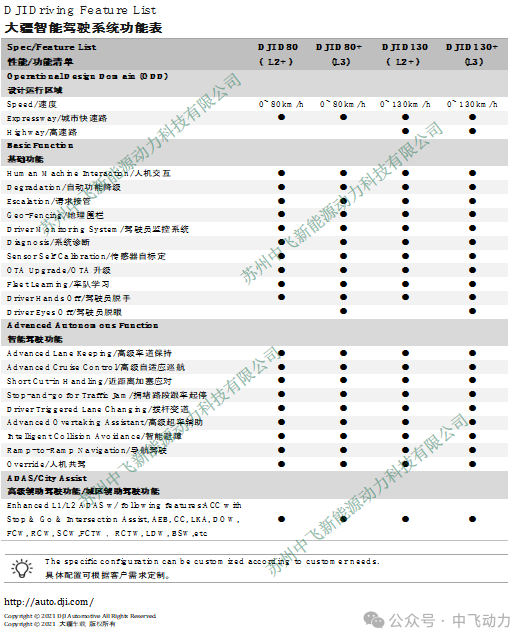

This table shows Zhuoyu’s current product line and product features. There are two L2+ products—D80 and D130, and two L3 products—D80+ and D130+.

As can be seen, the main differences between them lie in the speed range of autonomous driving, highway processing capability, and driver disengagement capability. To achieve driver disengagement, it is necessary to reach L3 (conditional autonomous control, driver attention does not need to focus on the road conditions) and above levels of autonomous driving.

To achieve low costs, Zhuoyu uses self-developed inertial dual-eye and laser systems as the core, providing high-precision ranging & high-resolution dense 3D point cloud information for the perception system, achieving safe and robust intelligent obstacle avoidance experiences. Upgrading the laser system can further enhance the performance experience in complex urban scenarios while meeting L3/L4 intelligent driving system redundancy architecture design requirements.

D130 supports a set of 8 million pixel inertial dual-eye cameras at the front, a 3 million pixel rear driving assistance monocular camera at the rear, 4 3 million pixel surround cameras, one millimeter wave radar at the front, and 12 ultrasonic radars at the front and rear of the vehicle.

Overall Appearance

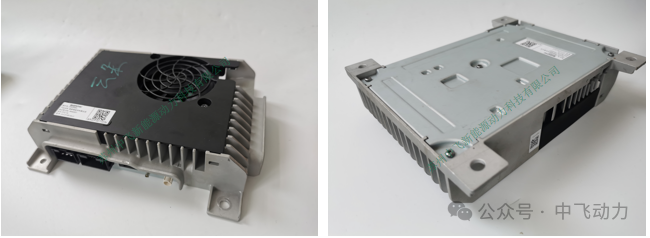

This image shows the appearance of the intelligent driving controller. Total weight 1.3kg.

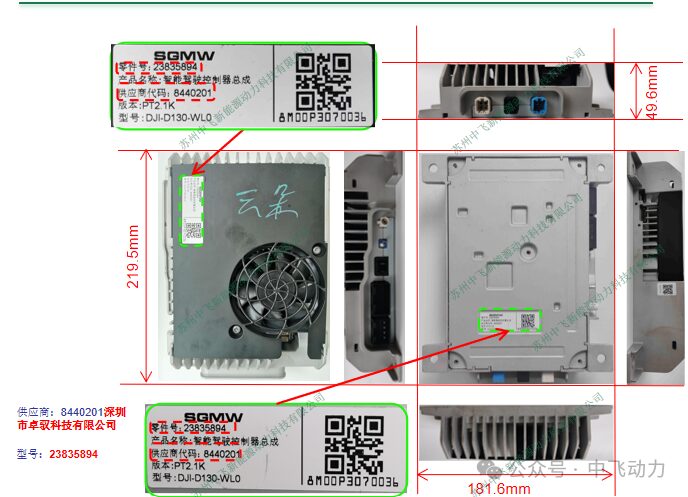

The size of the intelligent driving controller is as shown. Length 219.5mm, width 181.6mm, height 49.6mm. The company logo is SGMW SAIC General Wuling. Supplier code 8440201, i.e., Shenzhen Zhuoyu Technology Co., Ltd. It uses forced convection cooling.

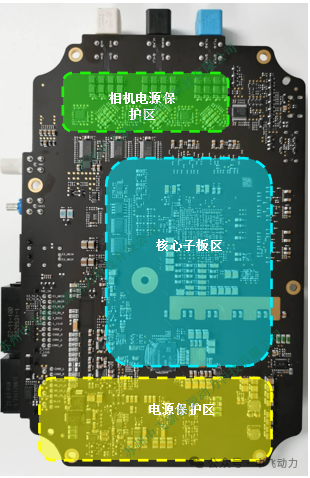

Opening the bottom cover, you can see the PCB and 6 thermal pads.

Flipping over the PCB, you can see the other side of the top cover and PCB. There are 15 thermal pads. Due to the large amount of thermal pad material used, it is difficult to open the PCB, and heating the central part is required before the PCB and top cover can be separated.

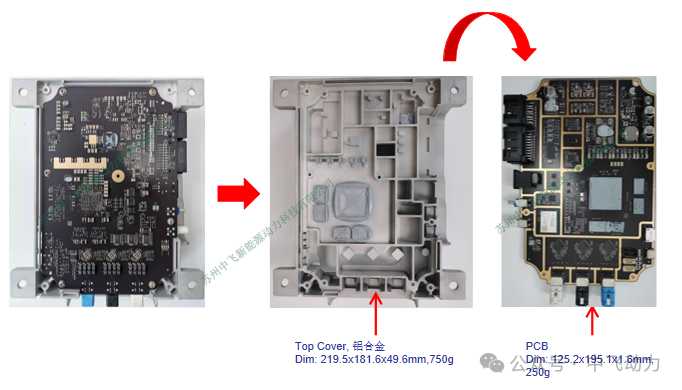

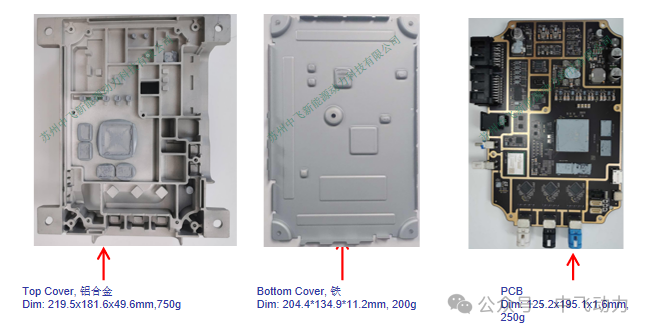

The main components are shown as unfolded, including the top cover, bottom cover, and PCB. The top cover material is aluminum alloy, 750g, accounting for 58% of the weight. The bottom cover material is iron, magnetic, 200g. PCB 250g.

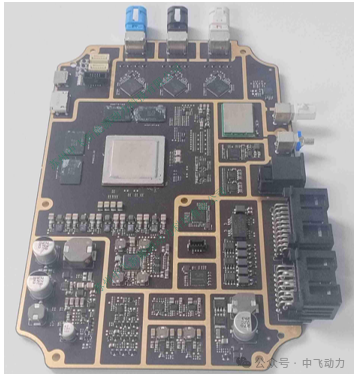

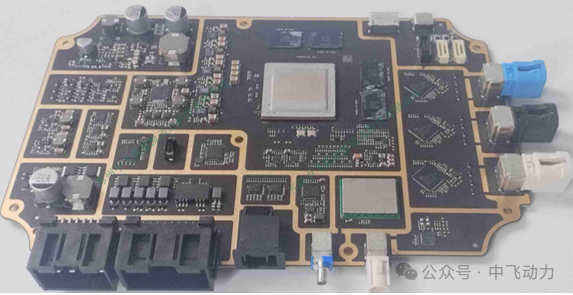

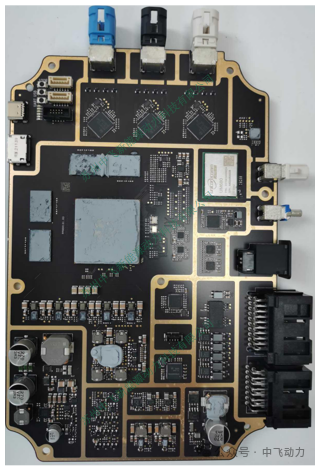

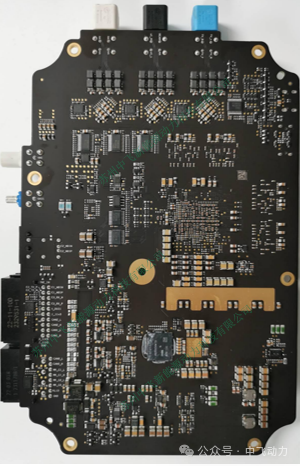

These two images are oblique views of the PCB.

This image shows the top view of the PCB

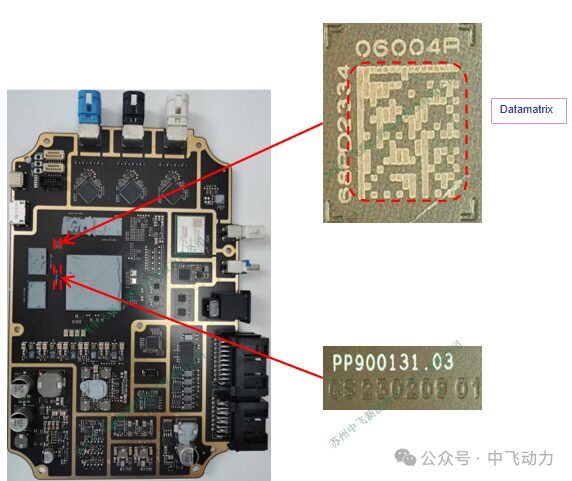

The PCB has silkscreen and QR codes for internal product management.

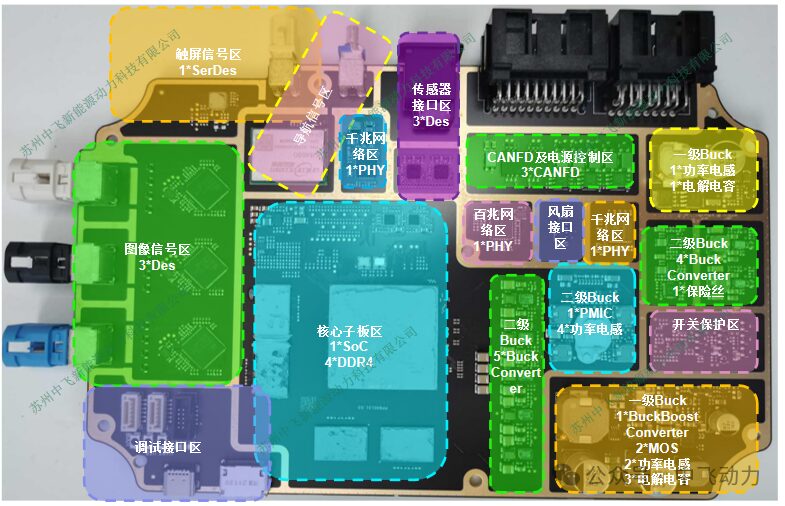

The main components are shown in the silkscreen diagram. The core components are in the center, including SoC and four DDR4 chips. The peripherals mainly consist of interface chips.

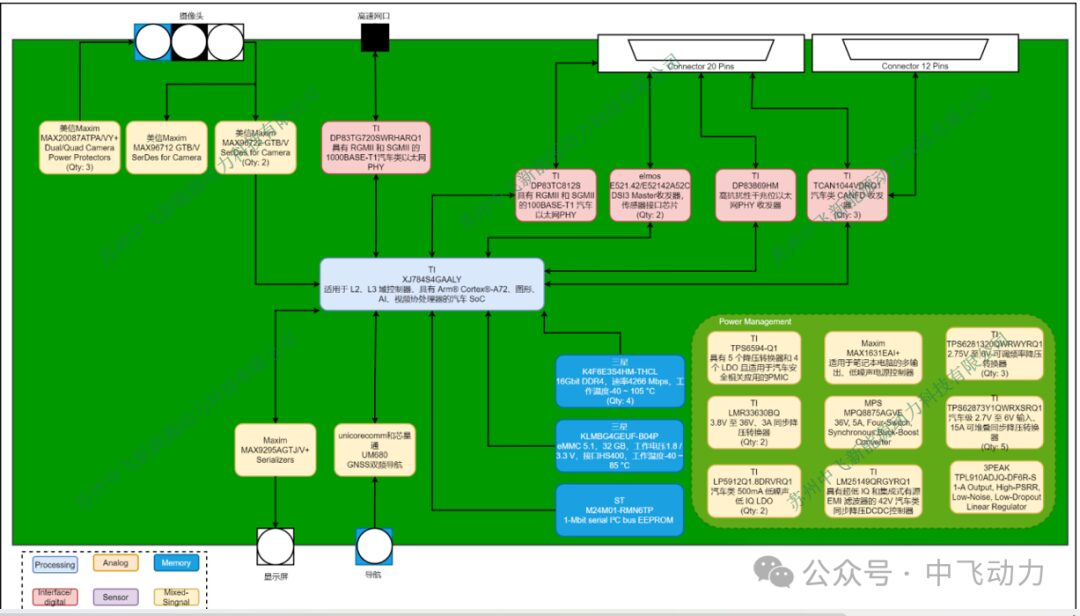

This image is the structural block diagram of the intelligent driving controller.

The core sub-board includes SoC and memory. The core of all intelligent driving controllers is SoC + high-performance memory + PMIC, with the importance of MCU being relatively low.

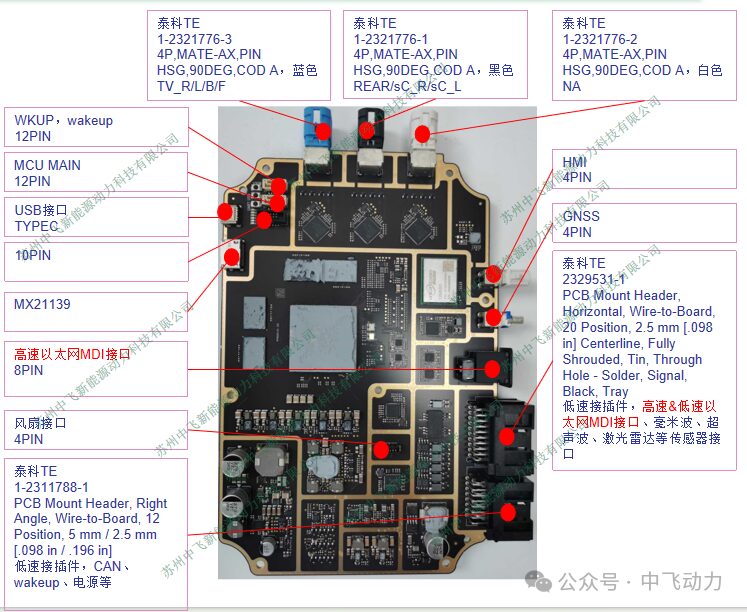

There are 20-pin and 12-pin connectors to achieve Ethernet, CANFD, sensor signal input/output, and power supply. These connectors belong to low-voltage low-speed connectors;

There are independent high-speed Ethernet interfaces, camera input interfaces, touch screen output interfaces, and navigation interfaces. These interfaces belong to high-speed connectors.

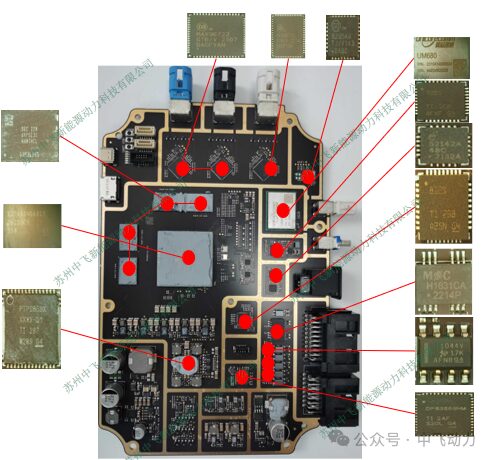

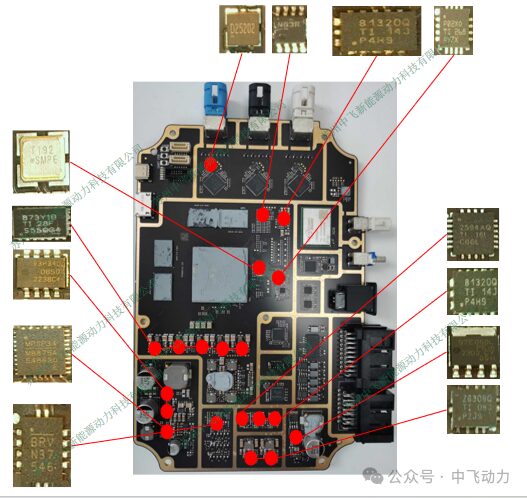

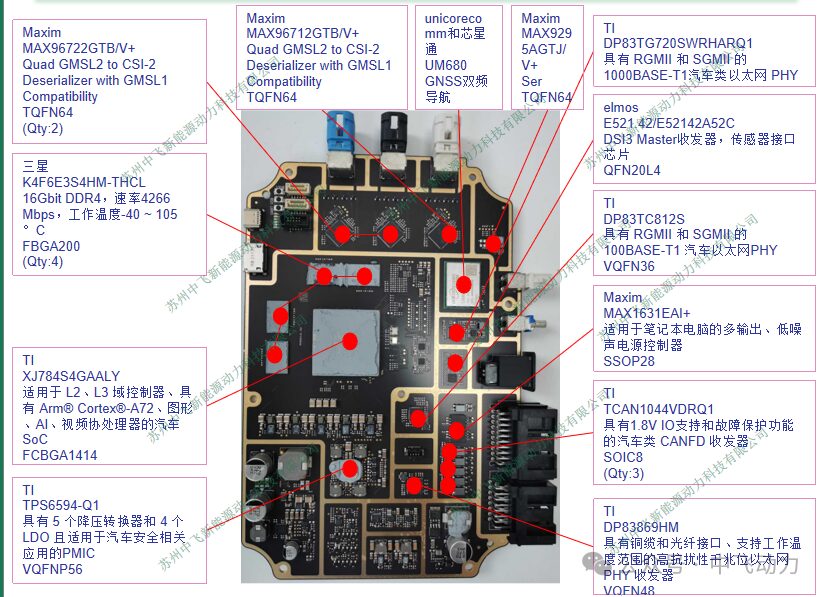

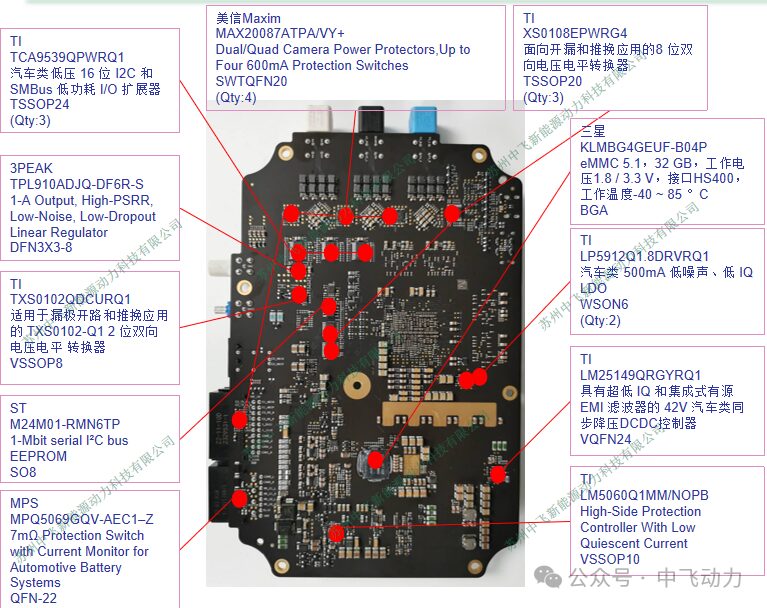

This is the model and other information of the main chips on the PCB front.

Samsung DDR4 (K4F6E3S4HM-THCL) is 16Gbit, with a rate of 4266 Mbps, working temperature -40~105 °C, FBGA200. A total of 4, totaling 64Gbit, or 16GBytes. Newer L4 intelligent driving controllers generally use DDR5 to achieve higher onboard RAM capacity and read/write speed.

2 Maxim MAX96722GTB/V+, 4-channel GMSL2 to CSI-2 Deserializer with GMSL1 Compatibility. TQFN64 package.

1 Maxim MAX96712GTB/V+, 4-channel GMSL2 to CSI-2 Deserializer with GMSL1 Compatibility. TQFN64 package.

GNSS dual-frequency navigation unicorecomm and chip star communication UM680.

1 MAX9295AGTJ/V+, GMSL2 plus serializer.

TI DP83TG720SWRHARQ1, is a 1000BASE-T1 automotive Ethernet PHY IC with RGMII and SGMII.

TI DP83869HM has copper and fiber interfaces, supports a wide temperature range and is a high-reliability gigabit Ethernet PHY transceiver, VQFN48 package.

TI DP83TC812S has RGMII and SGMII of 100BASE-T1 automotive Ethernet PHY, VQFN36 package.

The sensor interface chip is elmos E521.42/E52142A52C DSI3 Master transceiver.

There is also a Maxim MAX1631EAI+, suitable for laptops with multi-output, low-noise power controllers, SSOP28 package.

TI TPS6594-Q1 has 5 buck converters and 4 LDOs suitable for automotive safety-related applications, VQFNP56 package.

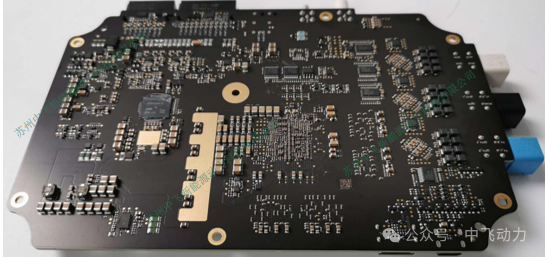

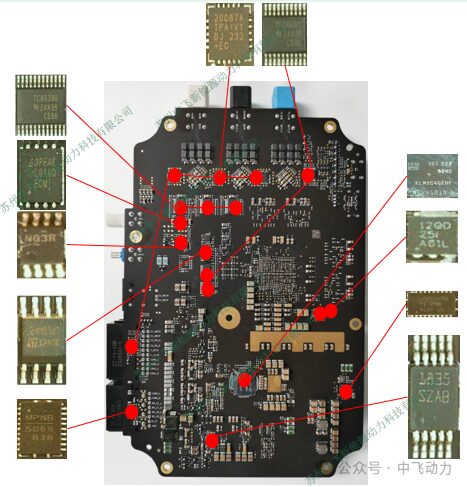

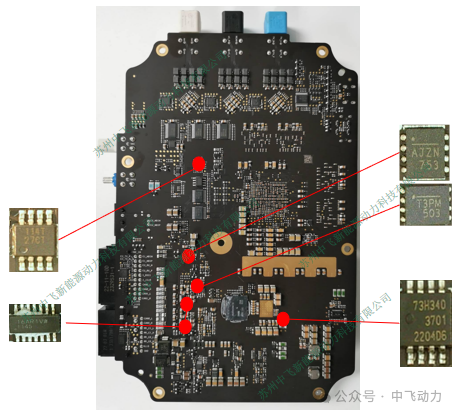

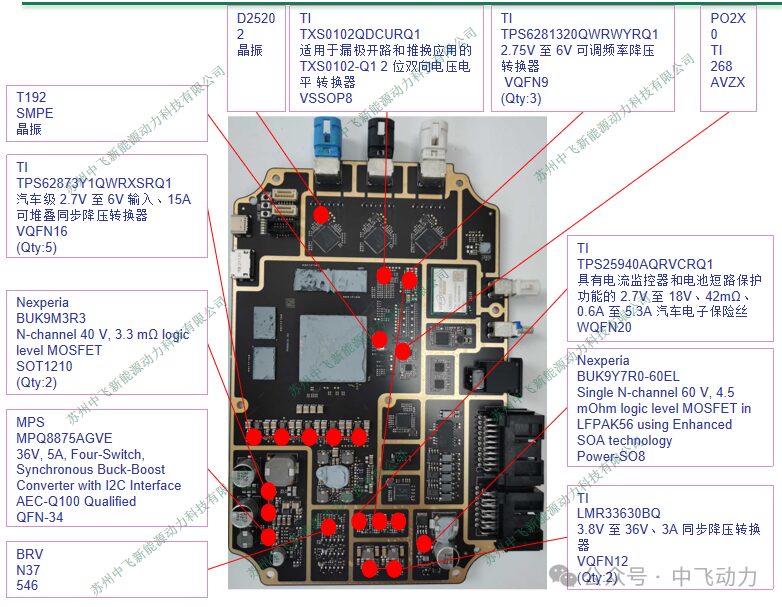

This image summarizes the models of the main chips on the PCB back. Besides EMMC5.1 and EEPROM memory chips, the majority are power and IO class chips.

EMMC5.1 has a capacity of 32GBytes, which is relatively abundant.

EEPROM is 1Mbit.

The power class ICs include MAX20087ATPA/VY+ Camera Power Protectors, LP5912Q1.8DRVRQ1 LDO, LM25149QRGYRQ1 DCDC controllers, TPL910ADJQ-DF6R-S linear rectifiers.

The image below summarizes the types of connectors used. Intelligent driving controllers generally have many types of connectors to meet different requirements for high-speed/low-speed, high current/low current, reliability, etc.

The core connectors include 3 video signal connectors, HMI display connectors, GNSS navigation connectors, high-speed Ethernet connectors, and 2 low-speed connectors.

In addition, there is a set of debugging connector combinations.

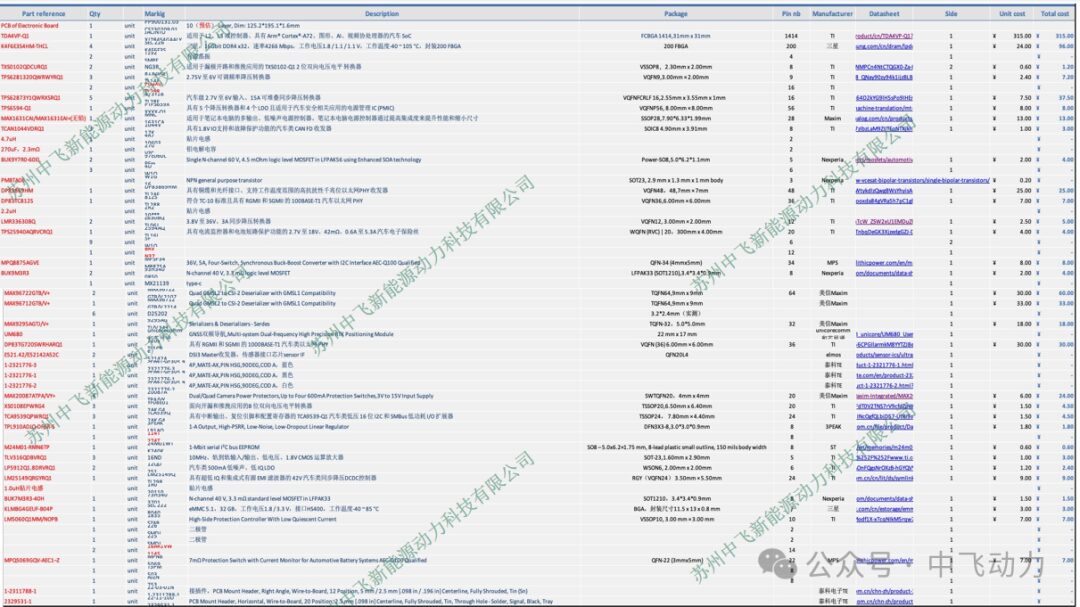

This table shows the BOM and price list of key chips.

Technical Analysis

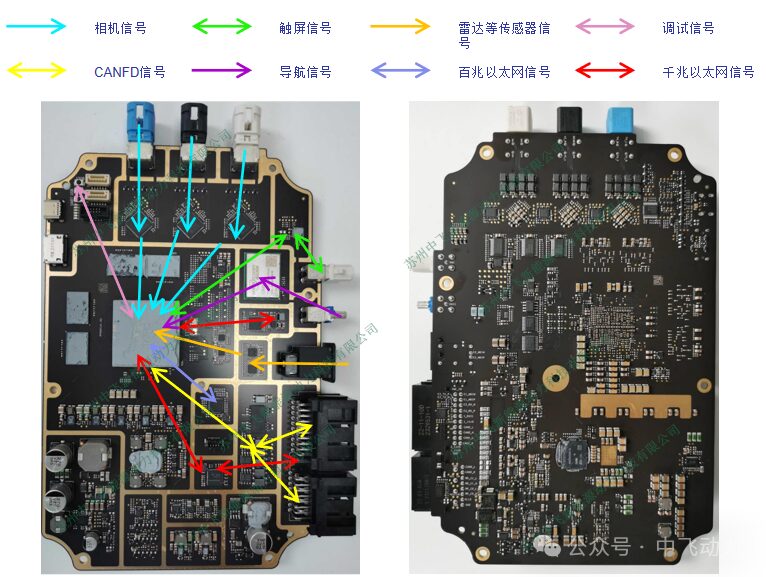

This image shows the control flow of the PCB. Control signals for wake-up, debugging, fans, etc., are transmitted through these pathways. In high-level intelligent driving controllers, synchronization signals are the most important control flow data, used for clock synchronization in the driving domain to improve the real-time and determinism of key data transmission such as images.

This image shows the data flow of the PCB. Image data, Ethernet data, radar data, navigation data, and CANFD data are all very important. The data interaction capability greatly affects the performance ceiling of the intelligent driving controller.

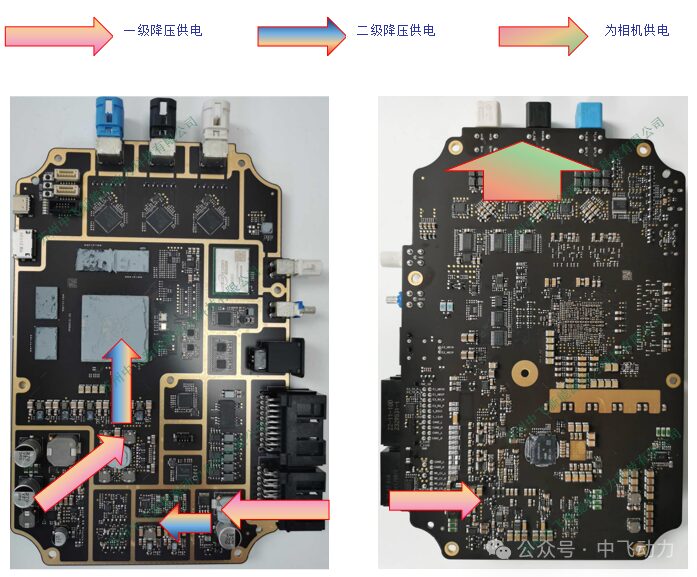

This image shows the power flow of the PCB. The power flow mainly comprises the power supply. This controller has one level of buck and two levels of buck. The first level of buck is mainly achieved through a combination of power inductors, aluminum electrolytic capacitors, DCDC controllers, etc., characterized by high power and high efficiency. The second level of buck is more dispersed, realized at multiple points, with each power point being small and diverse in implementation methods.

END