In the field of electronic device manufacturing, underfill materials play a crucial role in enhancing the reliability of electronic components. Today, we will delve into the knowledge regarding the selection and application of underfill materials as outlined in the IPC J-STD-030A standard.

The Importance and Types of Underfill Materials

As electronic products continue to evolve towards miniaturization and high performance, the connections between chips and circuit boards face greater challenges. Underfill materials have emerged to address these issues primarily by alleviating the mismatch in the coefficient of thermal expansion (CTE) between electronic packaging and assembly substrates, as well as enhancing mechanical strength to improve the reliability of electronic devices. Additionally, they provide environmental protection, resist mechanical shocks or vibrations, and even prevent tampering.

Currently, there is a diverse range of underfill materials available in the market. Capillary flow underfill materials, as the name suggests, flow under components relying on capillary action and can quickly cure to form a strong seal, making them suitable for assembly-level flip chips, although components must be inspected for defects before curing. Non-flowing/soldering underfill materials integrate the attachment, soldering, and curing processes into one, improving production efficiency, but they have higher viscosity and differ in many characteristics from capillary flow materials. Removable/reworkable underfill materials provide repair options for faulty components discovered in the factory or on-site, preventing waste from discarding entire components due to component failure. There are also corner bond adhesives and corner fill materials, which play roles at different stages of the process to meet various reliability enhancement needs.

Characteristics of Uncured Underfill Materials

Understanding the characteristics of uncured underfill materials is crucial for their correct use in production.

Fillers, as an important component of underfill materials, influence the performance of the material. Common fillers include silica and alumina, while boron nitride and other thermally conductive fillers may be selected for high-power heat dissipation applications. The particle size of the filler must be smaller than the effective gap size, with the maximum particle size generally being one-third of the minimum gap; otherwise, it will affect flow. Additionally, the content, density, and interactions with other components of the filler will also impact the performance of the underfill material.

The viscosity of the prepolymer changes over time, affecting the material’s flow rate and dispensability. The viscosity data provided by suppliers is under standard conditions, and actual use should refer to supplier documentation and consider real-world conditions. Gel time refers to the time when the liquid begins to exhibit pseudo-elasticity, influenced by the curing system and preheating conditions. During operation, it is essential to ensure that the gel point does not occur prematurely during filling to avoid affecting the filling effect.

Underfill materials must also be compatible with solder paste or flux residues, circuit board surfaces, and component surfaces. Flux residues may hinder the wetting of underfill materials or react with epoxy chemicals; moisture on the circuit board surface or uncured solder mask layers can affect filling effectiveness; moisture on component surfaces may also lead to filling defects. Furthermore, the α-particle emissions from certain underfill materials may affect memory devices, although suppliers typically select low α-emission fillers.

Key Points for Packaging, Handling, and Storage of Materials

The packaging, handling, and storage of underfill materials directly relate to their performance and usability. They are typically packaged in sealed plastic syringes, with labels indicating key information such as product, batch, and expiration date. During storage, most underfill materials need to be kept at low temperatures, with high filler content materials even requiring storage in low-temperature refrigerators to prevent filler sedimentation, slow down the curing process, and extend shelf life. New formulation materials have improved temperature stability, allowing for more relaxed storage conditions.

Materials taken out of the refrigerator need to undergo preconditioning to reach room temperature, avoiding moisture condensation and bubble formation. During handling, it is essential to follow the correct thawing steps to prevent thermal shock that could create voids in the syringe. The usability period of the material is influenced by various factors and can be assessed through viscosity changes, flow rate variations, and sedimentation tests to ensure use within the applicable period, guaranteeing the material’s dispensability, flowability, and curing effectiveness.

Application Process of Underfill Materials

The application process is a key step in ensuring that underfill materials perform their intended function. Before use, it is necessary to ensure that the circuit board is dry to prevent moisture from causing voids in the underfill material. For capillary flow underfill materials, the device must first be connected to the circuit board, which can be done using printing, dipping, or spraying flux methods, while minimizing flux residues.

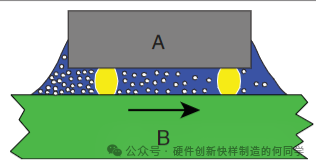

During dispensing, it is important to select the appropriate dispensing mode, such as dispensing from one, two, or three sides, as different modes vary in speed, corner width, and risk of air entrapment. The accuracy of dispensing parameters is also crucial, as the precision of the dispensing amount and gap tolerances will affect corner shape and filling effectiveness. Additionally, care must be taken to avoid issues such as air entrapment, gravity phase separation, dynamic phase separation, and filtration phase separation. The application of non-flowing/soldering underfill materials has different key points, with specific requirements for dispensing mode, dispensing amount, and component placement to ensure filling effectiveness and soldering yield.

Key Factors in the Curing Process

The curing process has a decisive impact on the final performance of underfill materials. After dispensing and flowing, the filling material should be cured as quickly as possible; if there is a long time interval, application life testing should be conducted to check for filler sedimentation and voids.

For capillary flow underfill materials, parameters such as heating rate, cooling rate, maximum temperature, and dwell time during the curing process will affect the final curing performance, such as glass transition temperature (Tg) and CTE. When formulating a curing plan, it is essential to consider the thermal mass of the components and circuit board to avoid under-curing. The curing of non-flowing underfill materials typically occurs in IR or convection surface mount reflow ovens, ensuring that solder joint reflow is completed before the filling material gels, and post-reflow baking may be necessary.

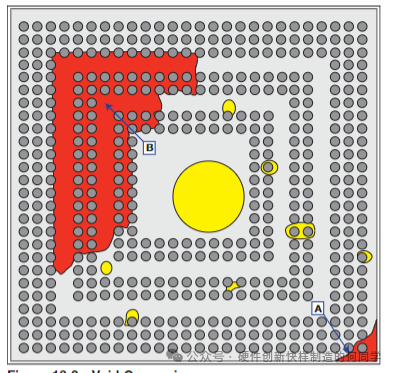

During the curing process, attention should be paid to void formation and degassing issues, with appropriate testing methods used to assess void formation. Additionally, the curing effect can be verified by comparing corners with known cured samples, using needle probe tests for hardness, and observing color changes; the most accurate method is to employ thermal analysis techniques such as differential scanning calorimetry (DSC) and thermomechanical analysis (TMA).

Evaluation of Properties of Cured Underfill Materials

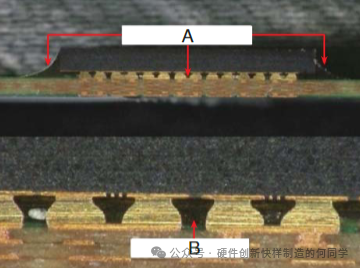

The properties of cured underfill materials directly relate to the performance and reliability of electronic devices. In terms of appearance, the formation of corners plays an important role in stress dispersion and reliability enhancement, with their height, volume, and expansion needing to meet certain standards and not cover the top of components. Most underfill materials are colored for visibility, with non-conductive dyes being a better choice.

Adhesion is an important indicator for evaluating the performance of underfill materials. Although directly measuring the bond strength with the solder mask is challenging, comparative assessments can be conducted using testing methods such as ASTM D1002. Shrinkage and induced stress can affect the stress state of components and can be measured using interferometry and other methods. Properties such as Young’s modulus, CTE, and Tg are also closely related to the performance of underfill materials, with different requirements in various application scenarios.

Furthermore, characteristics such as chemical stability, solvent resistance, moisture absorption, hydrolysis stability, non-nutritional properties, surface insulation resistance, electrochemical migration resistance, volume resistivity, and dielectric constant must be evaluated through appropriate testing methods to ensure that underfill materials can operate stably in various environments.

Process Reliability Assessment and Other Considerations

During production, process reliability assessment is indispensable. The ionic content of underfill materials should meet standards to prevent corrosion. Chemical resistance and mechanical integrity must also be tested to ensure that materials can protect components and solder joints in harsh environments while maintaining a strong mechanical connection between components and circuit boards.

Thermal cycling tests and drop tests are common reliability testing methods that simulate actual usage environments to assess the enhancement effect of underfill materials on device reliability under different stress conditions. For capillary underfill materials, the impact of post-soldering processes must also be considered, selecting materials that can withstand high temperatures to avoid issues in subsequent processes.

In other considerations, reworkability is an important factor. When rework costs are reasonable, reworkable underfill materials can provide manufacturing flexibility. The best way to determine the degree of curing is through DSC analysis to ensure that the filling material is fully cured. For heat dissipation needs, underfill materials with better thermal conductivity can be selected, but the commonly used spherical silica fillers have limited thermal conductivity. Additionally, there are process standards for BGA and CSP board-level underfill materials, destructive testing, and process guidelines for corner or edge bonding underfill materials that must be strictly followed during production.

Common Issues Troubleshooting and Solutions

During the use of underfill materials, various issues may arise that need to be promptly identified and resolved.

If there is insufficient flow, it may be due to abnormal viscosity, poor wettability, or mechanical blockage. In this case, viscosity should be measured, and the surface checked for contaminants, while investigating whether there are mechanical hindrances such as excessively small gaps or excessive flux residues.

Phase separation issues may arise from blockages or the properties of the material itself; for low-viscosity systems, consider changing materials or adjusting processes. Voids are a common issue, with pre-curing voids possibly stemming from poor flow patterns, bubbles in material packaging, or improper dispensing parameters; post-curing voids may result from air entrapment, moisture evaporation, filler evaporation, or insufficient reaction of flux residues, requiring targeted measures such as optimizing flow patterns, pre-drying components, or adjusting curing curves.

Under-curing issues are typically caused by insufficient temperature and time, which can be resolved by inserting thermocouples to test actual temperatures or assessing the compatibility of materials with other components. Poor adhesion may result from contaminants, moisture on the substrate, or material mismatches, which can be improved by increasing curing temperatures, pre-baking, or changing materials. Thermal cycling failures are caused by a combination of factors, requiring analysis of failed units to identify specific causes and take targeted measures.

Underfill materials are of great significance in electronic manufacturing. By adhering to the IPC J-STD-030A standard and rigorously controlling every aspect from material selection, storage, application to curing, and promptly identifying and resolving issues, we can fully leverage the role of underfill materials, enhance the reliability of electronic devices, and drive the continuous advancement of the electronic manufacturing industry. We hope today’s sharing provides a deeper understanding of underfill materials, enabling you to apply this knowledge in your work to solve encountered problems.

References:IPC J-STD-030A (with illustrations), standards may not be absolute, but they are certainly a comprehensive summary of valuable experiences.