Today, I would like to share with you the 8 common PCB markings.

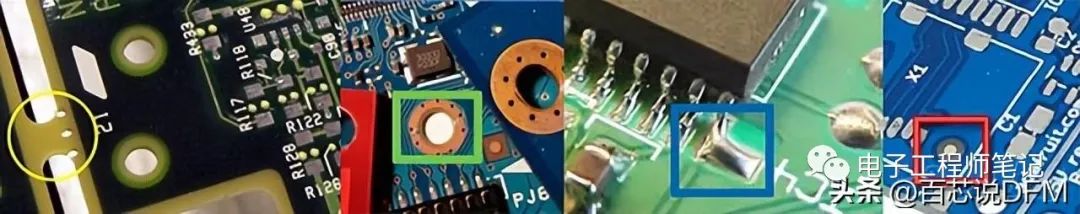

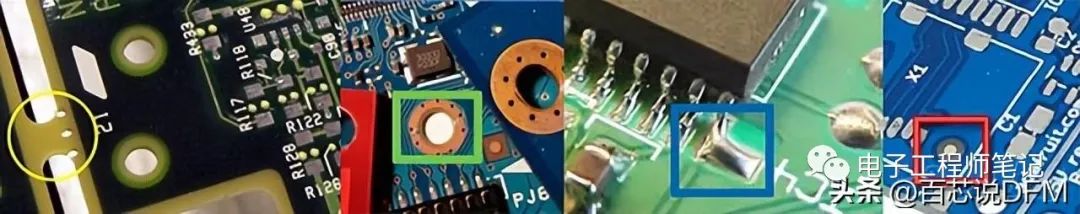

From left to right: Stamp hole – Via type – Solder mask pad – Reference mark

From left to right: Stamp hole – Mounting hole – Solder mask pad – Reference mark

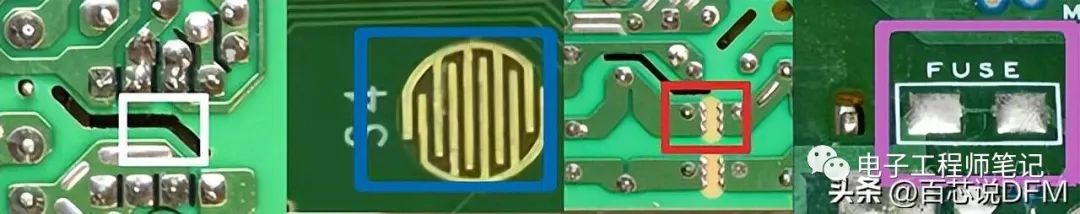

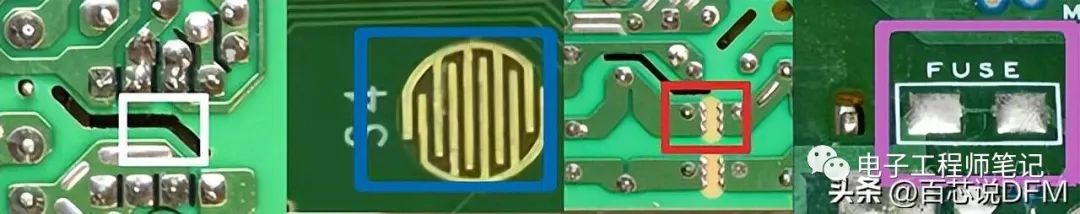

From left to right: PCB slot, PCB button, spark gap, and fuse trace

From left to right: PCB slot, PCB button, spark gap, and fuse trace

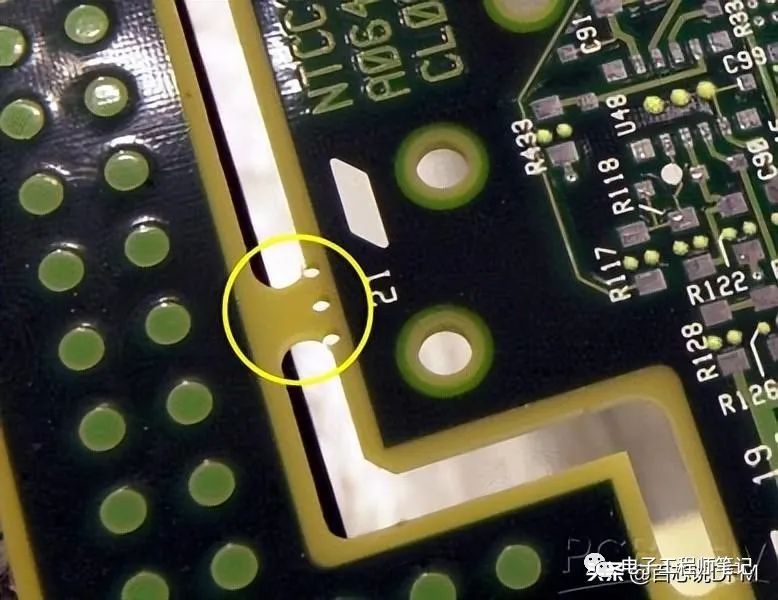

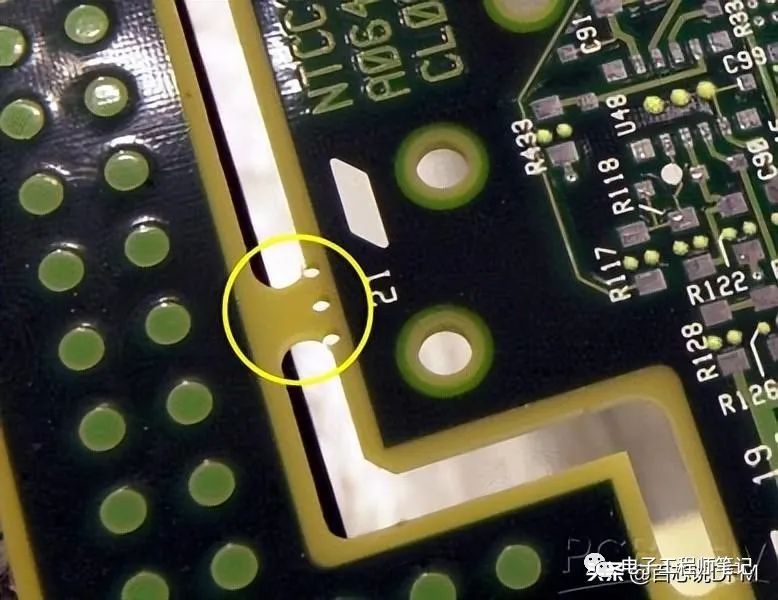

1. PCB Stamp Hole

Stamp hole

When assembling boards, a small contact area is reserved in the middle to facilitate the separation of PCBs, and the holes in that area are called stamp holes.

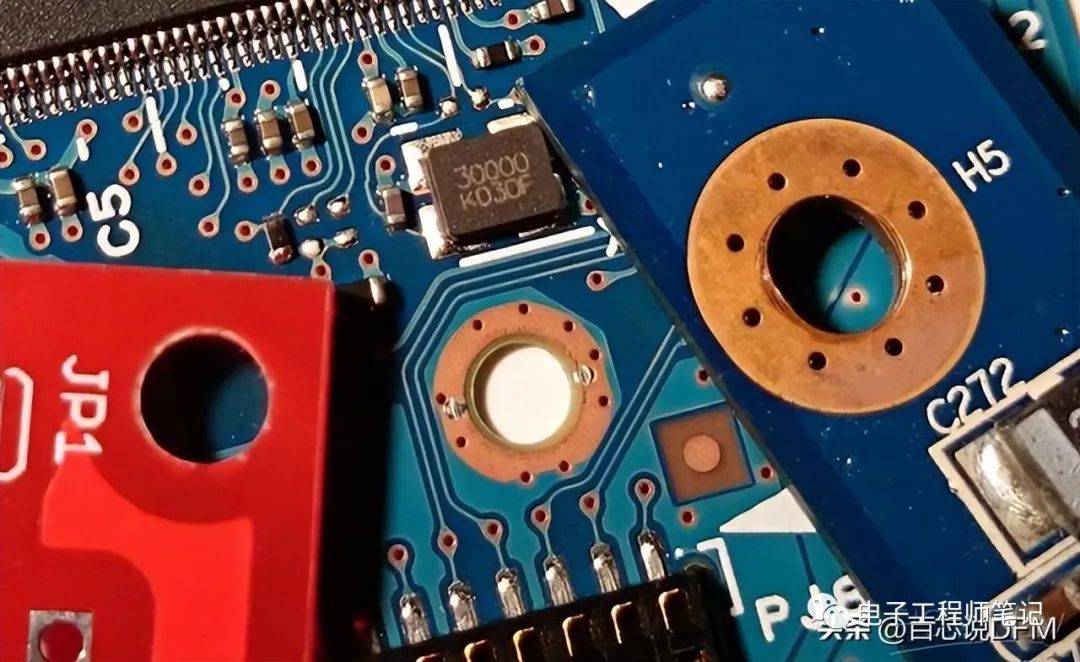

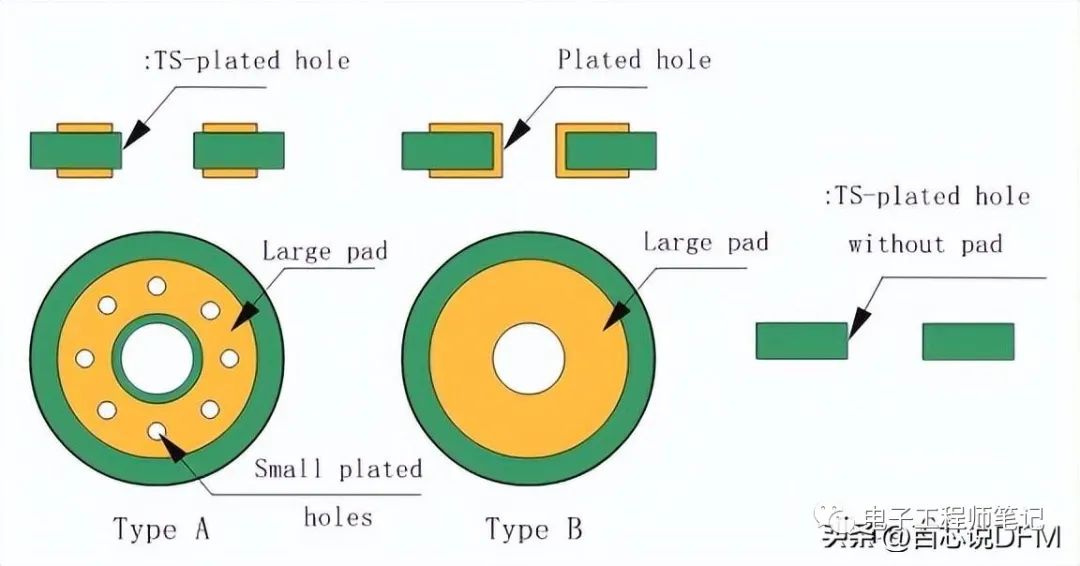

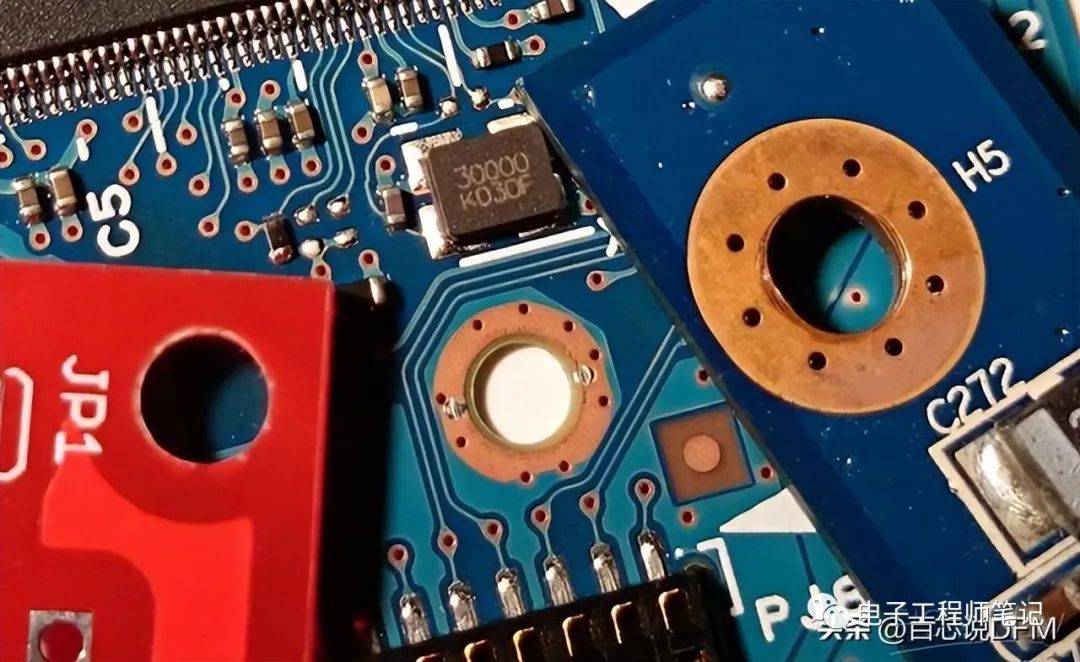

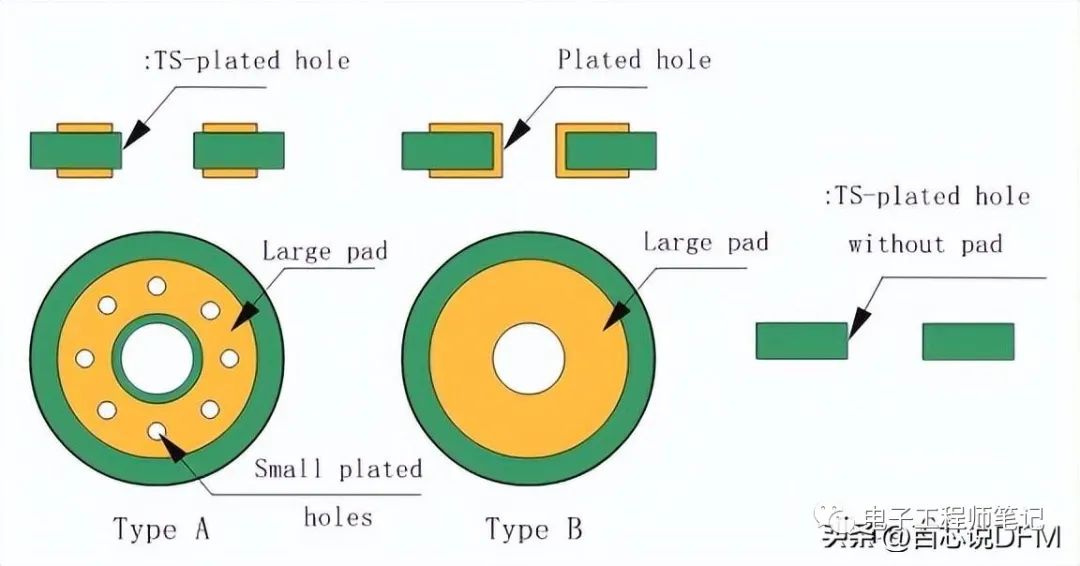

2. PCB Via Types

PCB via types

In many cases, you will see that the mounting holes are surrounded by small vias. There are mainly 2 types of mounting holes: plated and non-plated. There may be 2 reasons for using the surrounding vias:

-

When we want to connect the hole to the inner layer (such as GND in a multilayer PCB)

-

In the case of non-plated holes, when we want to connect the upper and lower pads

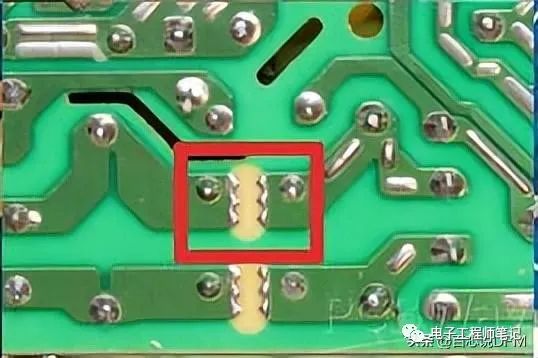

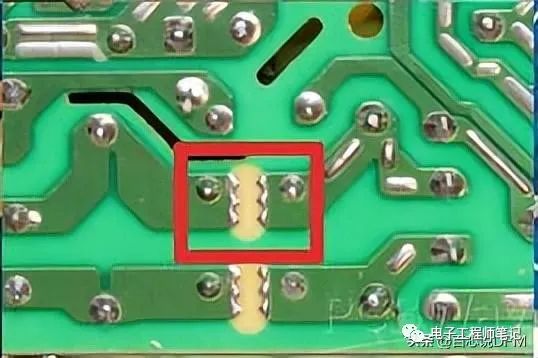

3. Solder Mask Pad (Solder Paste Theft)

One of the defects of wave soldering is that solder bridges easily occur during the SMD soldering process. As a solution, it was found that using an additional pad at the end of the original pin can resolve this issue. The width of the additional pad is 2-3 times that of a regular pad.

It is also known as solder paste theft, as it absorbs excess solder and prevents solder bridges.

Solder mask pad

4. Reference Mark (Mark Point Marking)

Reference mark

A larger bare circle contains a bare copper circle. This reference mark serves as a reference point for pick-and-place (PnP) machines. The reference mark is located in three positions:

-

In the panel.

-

Next to small pitch components like QFN, TQFP, etc.

-

At the corners of the PCB.

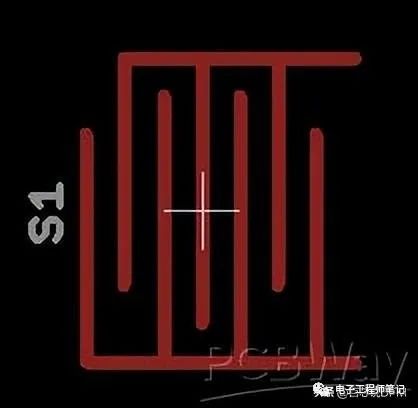

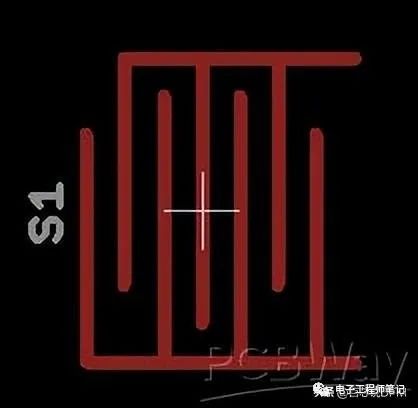

5. Spark Gap

The spark gap is used for ESD, current surge, and overvoltage protection. High voltage can ionize the air between two terminals, forming a spark between them before damaging the rest of the circuit. This protection method is not recommended, but it is better than having none, with the main drawback being that performance can change over time.

The breakdown voltage can be calculated using the following formula: V=((3000×p×d)+1350)

Where “p” is atmospheric pressure and “d” is the distance in millimeters.

Spark gap

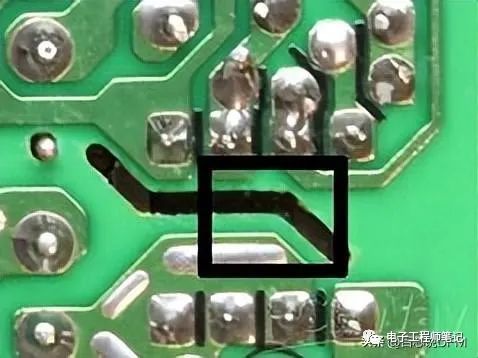

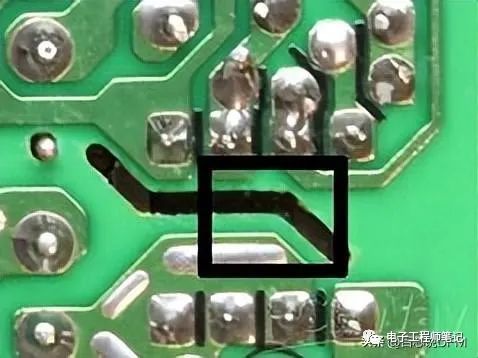

6. PCB Conductive Button

PCB conductive button

If you have disassembled a remote control or a calculator, you should have seen this marking. The conductive button consists of 2 interleaved terminals (but not connected). When the rubber button on the keyboard is pressed, the two terminals connect because the bottom of the rubber button is conductive.

PCB conductive button

7. Fuse Trace

Similar to the spark gap, this is another cheap technique used in PCBs. The fuse trace is a necked trace on the power line, acting as a one-time fuse. The same configuration can also be used as a PCB jumper by simply etching the necked trace to remove a specific connection (PCB jumpers can be found on the reset line of some Arduino UNO boards).

Fuse trace

8. PCB Slot

If you look at the PCBs of high voltage devices such as power supplies, you may notice air slots between certain traces.

Temporary arcs that repeatedly occur in PCBs can cause carbonization, leading to short circuits. To address this, routing slots can be added in suspected areas, which will still experience arcing but will not carbonize.

PCB slot

Source: Electronic Circuit

Disclaimer: This article is copyrighted by the original author and does not represent the views of the association. The articles promoted by the “Jiangxi Province Electronic Circuit Industry Association” are for sharing purposes only and do not represent the stance of this account. If there are copyright issues, please contact us for deletion.