From Principles to Programming: A Step-by-Step Guide to PLC Analog Input Temperature Measurement

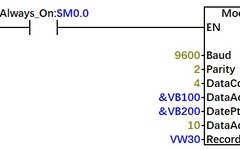

Click the blue text above to follow us Task Control A certain equipment manufacturer uses a temperature sensor to measure the workshop temperature, with a range of -30℃ to 150℃. When the measured workshop temperature is -30℃, the current output from the sensor is 0mA, corresponding to a PLC digital value of 0; when the … Read more