Wow, do you know where the water we flush goes? — The answer is the wastewater treatment plant! But you might not expect that behind these “stinky pools” lies a super intelligent control system.

As a veteran in industrial control with ten years of experience, today I will unveil the mystery of modern wastewater treatment plants and see how the quietly working “brain” — the Siemens PLC control system — commands this massive “washing machine” 24/7, turning our wastewater into clear, drinkable water.

Why does wastewater treatment need PLCs? Don’t joke!

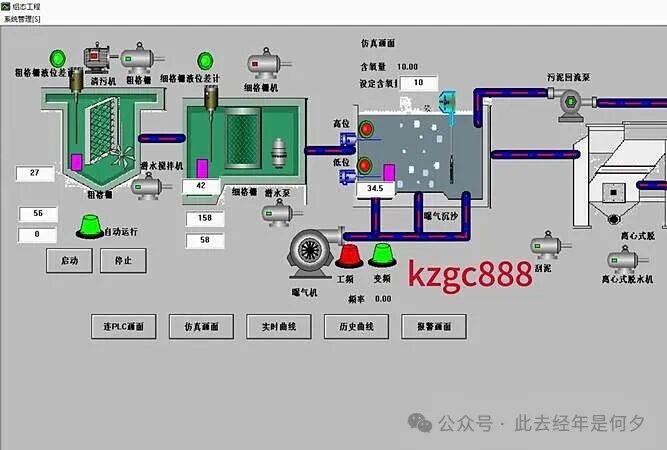

Imagine if we had to manually control a wastewater plant processing 100,000 tons/day… It would be as terrifying as letting a monkey fly a plane! Wastewater treatment involves hundreds of pumps, fans, valves, and dozens of water quality parameters monitored in real-time; how could we manage without an automation system?

The Siemens S7-1500 series PLC is the “perfect commander” — it can handle hundreds to thousands of I/O points simultaneously, execute complex control logic, and operate 24 hours a day without eating, drinking, or complaining. No wonder German industry is so strong!

Revealing: How PLC Monitors the Entire Wastewater Treatment Process

Let’s start with something interesting — did you know? A drop of wastewater takes an average of 8-12 hours to go from entering to exiting the plant. This process is divided into multiple treatment units, each precisely controlled by a PLC:

1. Inlet Pump Station Control (The “Welcoming Ceremony” for Domestic Wastewater)

The inlet pump station is like the “front door” of the wastewater plant, where the PLC is mainly responsible for:

-

Water level detection and pump station start/stop

-

Automatic control of the bar screen for debris removal

-

Flow balancing adjustment

Take a look at this control program for the bar screen; it’s simple but crucial:

armasm copy // Bar screen automatic control ladder diagram

LD “Water Level Sensor”

"Set Water Level Upper Limit"

AND “Bar Screen_Run Allowed”

S “Bar Screen_Start”

LD “Water Level Sensor”

< “Set Water Level Lower Limit”

OR “Bar Screen Blockage Detection”

R “Bar Screen_Start”

It’s that simple — when the water level exceeds the upper limit and running is allowed, the bar screen starts; when the water level drops below the lower limit or a blockage is detected, the bar screen stops.

2. Biochemical Treatment System (The “Spa Journey” for Wastewater)

This is the core of the entire treatment process and the most complex part controlled by the PLC. Modern wastewater plants often use the A²/O process (Anaerobic-Anoxic-Aerobic), which requires precise control of:

-

Dissolved Oxygen Concentration (DO)

-

Return Ratio

-

Aeration Fan Speed

-

Sludge Discharge Cycle

Let’s see how we achieve dissolved oxygen control through PLC:

Copy // DO closed-loop PID control FBD code

“Measured DO” -> IN1

“Target DO” -> IN2

“PID_Compact_1” (

Setpoint := IN2,

Input := IN1,

Output => "Fan Frequency Output"

)

This control step seems simple, but it is the soul of wastewater treatment! Too low DO leads to poor treatment effects, while too high wastes energy. I once saw a plant save over 300,000 in electricity costs annually by optimizing this program! Who says programmers can’t change the world?

3. Disinfection and Discharge Control (The “Graduation Ceremony” for Wastewater)

The treated water needs to be disinfected before discharge, and the PLC is responsible for:

-

Automatic adjustment of sodium hypochlorite dosage

-

Monitoring and recording of effluent flow

- Online water quality analysis and alarms

Intelligent Upgrade: How I Revitalized an Old Wastewater Plant

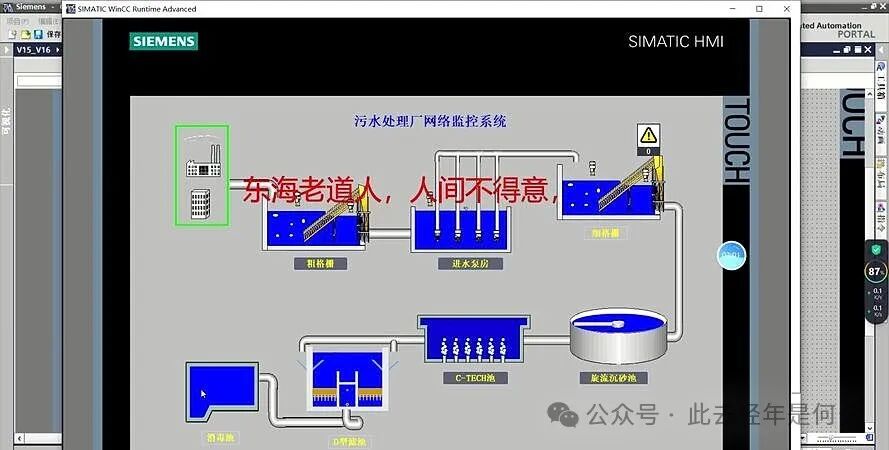

Three years ago, I took over a renovation project for an old wastewater plant built in 2005. The original control system was a Siemens S7-300, which had been running for 15 years — quite an old age in the PLC world!

What was the most troublesome? Those yellowed documents and incomprehensible comments…

After the renovation, we replaced the old controller with an S7-1500 and added the following features:

-

Energy Consumption Optimization Control: Automatically adjusts fan power based on influent water quality, saving over 30% on electricity

-

Remote Monitoring System: Allows viewing of plant operation status via a mobile app through the SCADA system

-

Fault Prediction: Uses motor current trend analysis to predict equipment failures for early maintenance

What’s the most interesting part? During the debugging phase, the system indicated an abnormal current for the No. 1 sludge pump in the secondary sedimentation tank. The maintenance personnel insisted that “the pump is fine,” but PLC data doesn’t lie — ultimately, when we opened the pump body, we found a… pair of underwear inside! Everyone was convinced after that.

From PLC Novice to Wastewater Treatment Expert: Skills You Need to Master

If you want to enter the field of wastewater treatment automation, you need to learn:

-

Siemens TIA Portal programming environment

-

SCL structured programming language (essential for handling complex algorithms)

-

Basic knowledge of wastewater treatment processes

-

PROFINET industrial Ethernet communication

Don’t be afraid! Starting from scratch, you can get the hang of basic control system development in three months. My first project was to control a small MBR system with S7-1200, and the result… I blew the membranes! What a painful lesson!

Final Words

PLC is like the “unsung hero” of the wastewater treatment plant, working silently yet determining the efficiency and stability of the entire system. Just think, every time you press the toilet flush button, behind it is a complex system controlled by Siemens PLC tirelessly working to protect our rivers and lakes.

I often tell my team — writing PLC programs is not for the boss, it’s for every one of us who drinks water. This might be the romance of industrial control people!

If you have any questions about wastewater treatment or PLC control, feel free to discuss in the comments, and I will do my best to answer every question!