Skip to content

A semiconductor laser is a device that generates laser light through the principle of PN junction stimulated emission. Its excitation methods include electrical injection, optical pumping, and high-energy electron beam excitation.

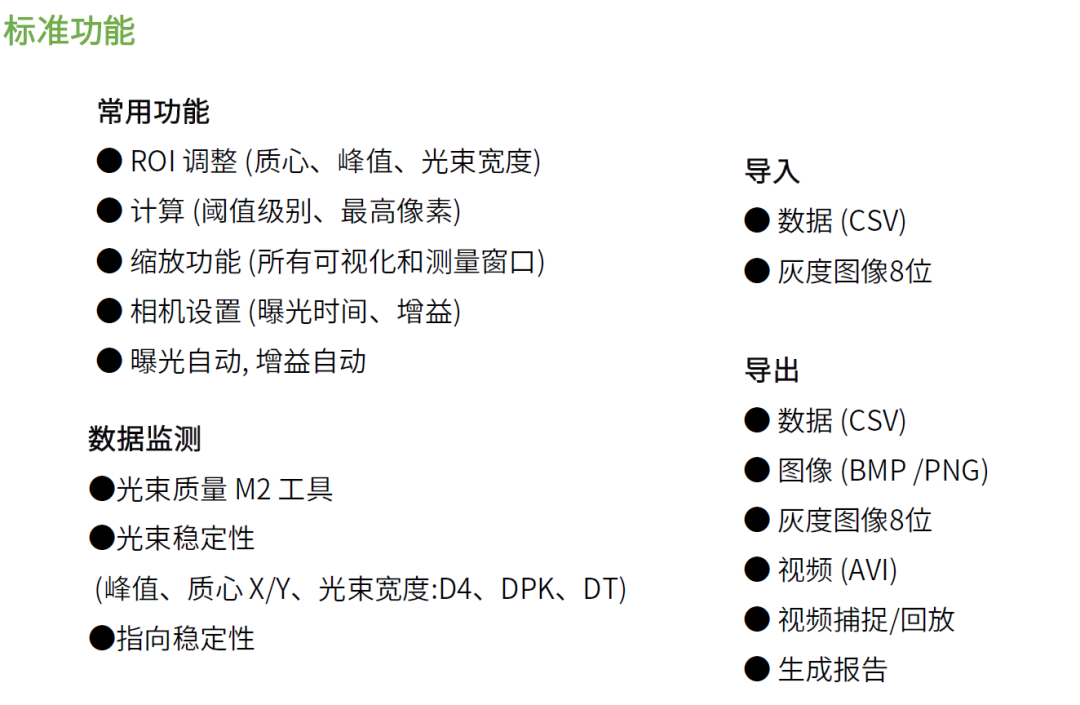

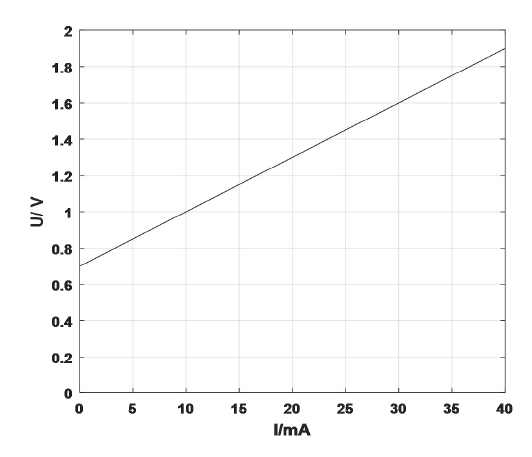

When designing the driving circuit for semiconductor lasers, it is essential to understand its working principle, but more importantly, to study its working characteristics. The main working characteristics of semiconductor lasers include U-I characteristics, P-I characteristics, threshold characteristics, and temperature characteristics.

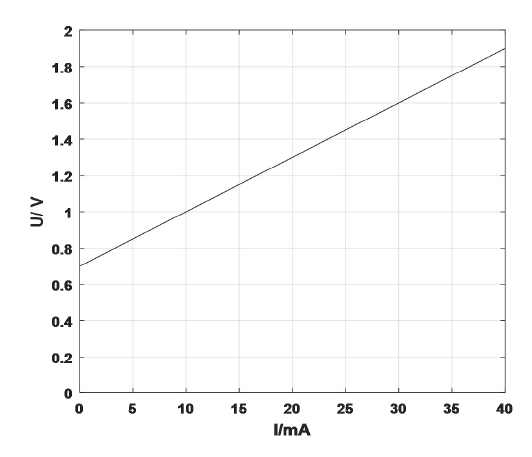

U-I Characteristics of Semiconductor Lasers

The volt-ampere characteristics of semiconductor lasers are similar to those of diodes. The following diagram shows the U-I characteristics of semiconductor lasers. The U-I characteristic curve reflects the quality of its PN junction and is used to estimate its equivalent resistance value. After the semiconductor laser is powered on, a forward voltage U is generated across its terminals. When the forward voltage U is small, the external electric field cannot overcome the resistance to the diffusion motion of majority carriers within the PN junction, resulting in a very small current. When the forward voltage U becomes sufficiently large, the internal electric field is significantly weakened, and the current gradually increases linearly.

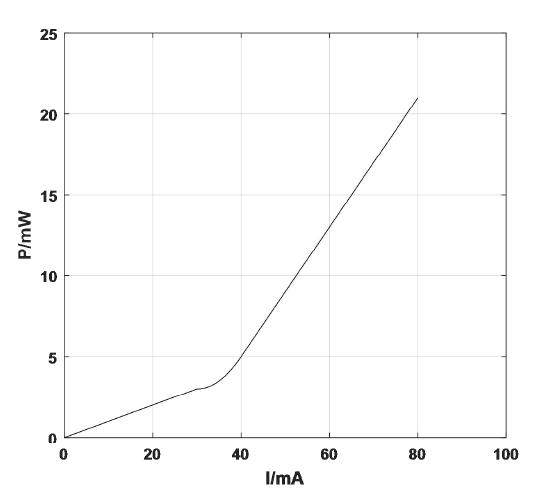

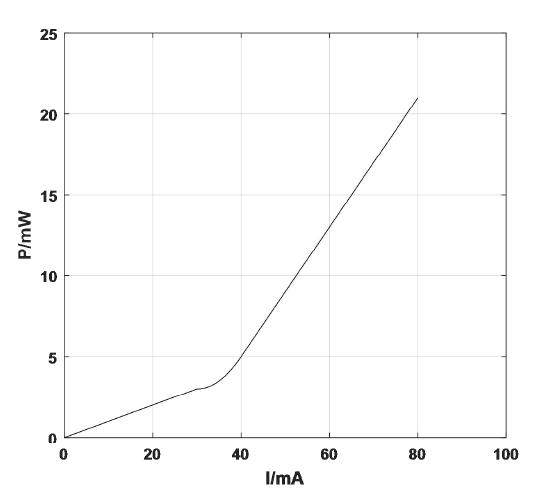

P-I Characteristics of Semiconductor Lasers

The ideal P-I characteristics of a semiconductor laser are shown in the figure. As the driving current I increases, the output optical power P continuously increases, but the relationship between them is not simply linear. Understanding and mastering the P-I characteristics is crucial when designing the driving system for semiconductor lasers.

Threshold Characteristics of Semiconductor Lasers

Analyzing the P-I characteristic curve of semiconductor lasers reveals three stages in the relationship between power and driving current.

The first stage occurs when the driving current is small, and the semiconductor’s ability to deliver carriers is insufficient. There are few electrons and holes in the PN junction region, and at this point, stimulated emission is less than absorption, so no light is emitted.

The second stage occurs as the driving current increases, leading to a gradual increase in the number of electrons and holes. At this point, light amplification occurs, although the emitted light is still fluorescence, it is stronger than in the first stage; however, the stimulated emission (optical gain) is still weaker than the cavity loss, so light oscillation cannot occur.

The third stage continues as the driving current increases, at which point the concentration of electrons and holes in the PN junction reaches a certain value, and the optical gain begins to exceed the cavity loss, allowing the semiconductor laser to emit laser light. At this stage, the output optical power of the laser is linearly related to the driving current. Given the above working characteristics of semiconductor lasers, the output optical power can be adjusted by regulating the driving current.

In the operation of semiconductor lasers, the critical driving current value at which laser emission begins is called the threshold current. Only when the driving current exceeds the threshold current can the semiconductor laser operate normally and emit laser light. Therefore, the threshold current is an important working characteristic of semiconductor lasers.

The size of the threshold current is influenced by various factors, mainly including the material characteristics, structural characteristics, and operating temperature of the semiconductor laser. Since the primary excitation method of semiconductor lasers is electrical injection, the output optical power of semiconductor lasers mainly depends on their driving current.

When the driving current exceeds the threshold current, the greater the driving current, the greater the output optical power, and the two exhibit a linear relationship. Unfortunately, as the driving current increases, the heat generated by the semiconductor laser also increases, and the temperature rise caused by this heat will increase the threshold current, directly affecting the stability of the output optical power. Therefore, to ensure the normal and stable operation of semiconductor lasers, it is necessary to address the stability issues of the driving current and operating temperature.

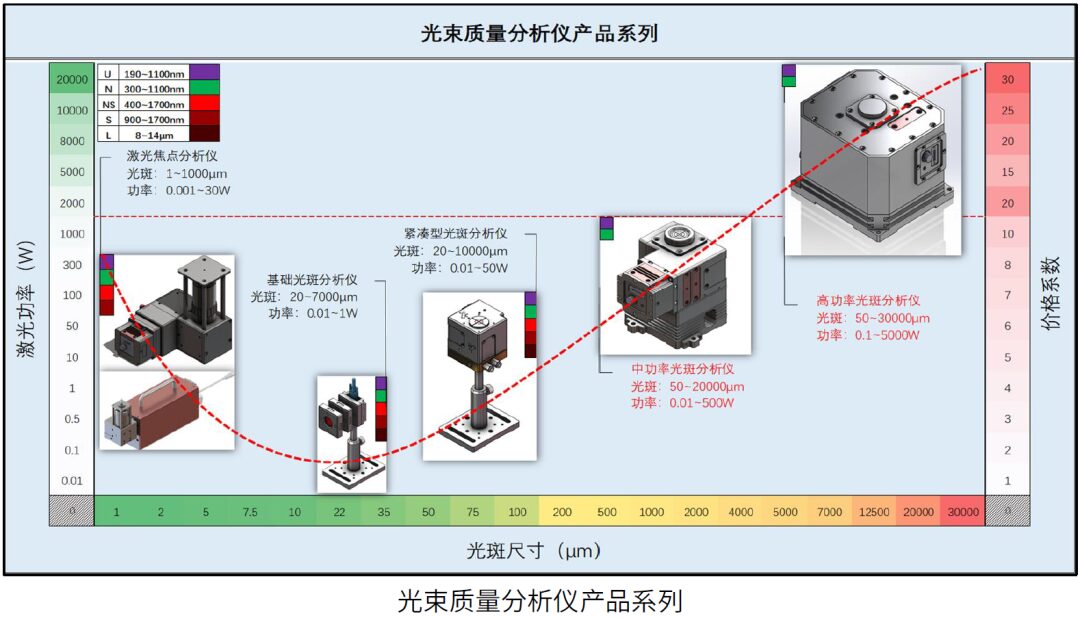

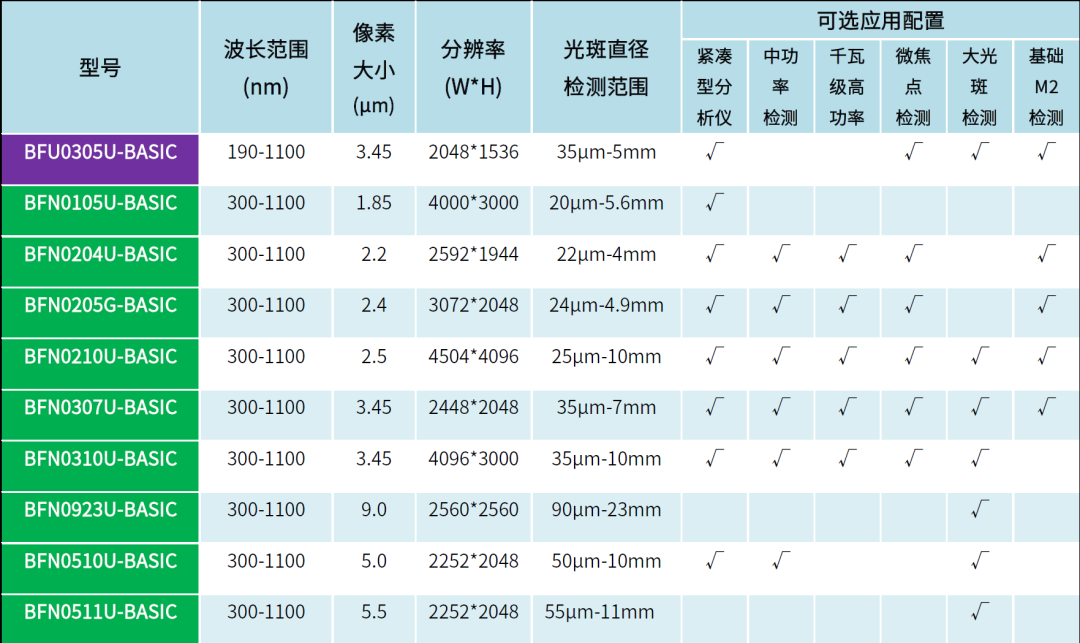

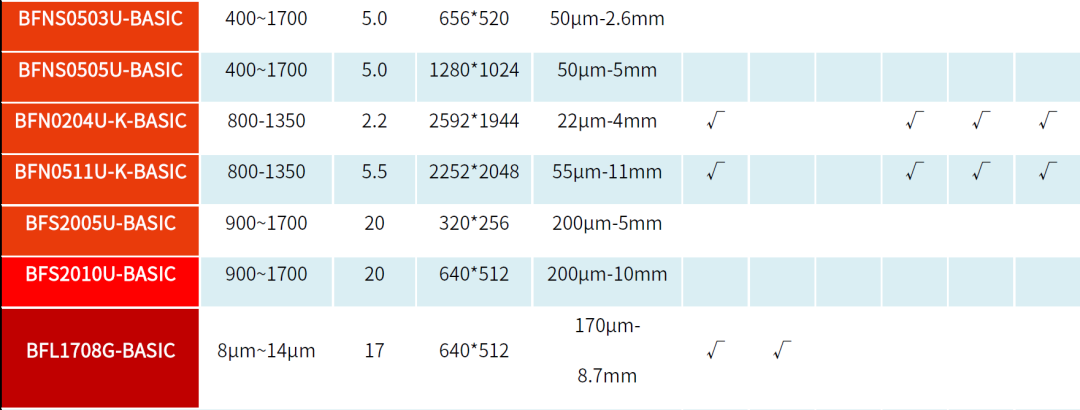

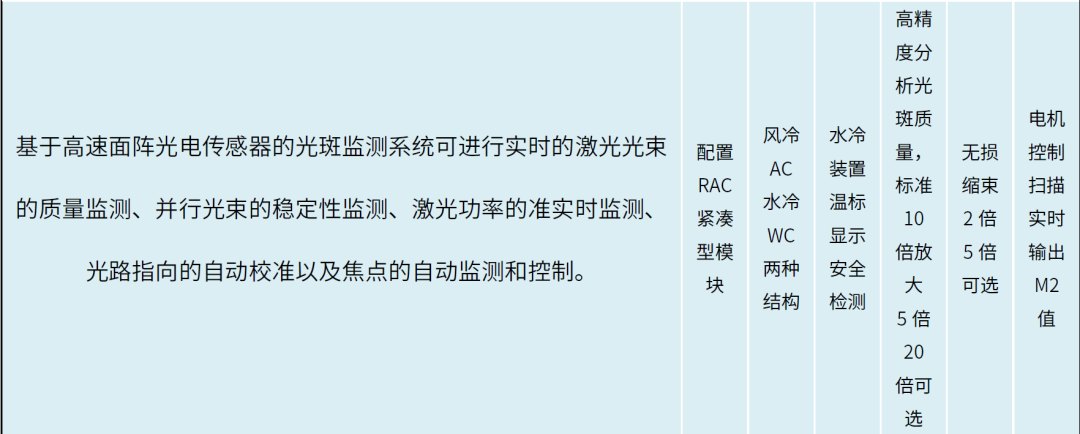

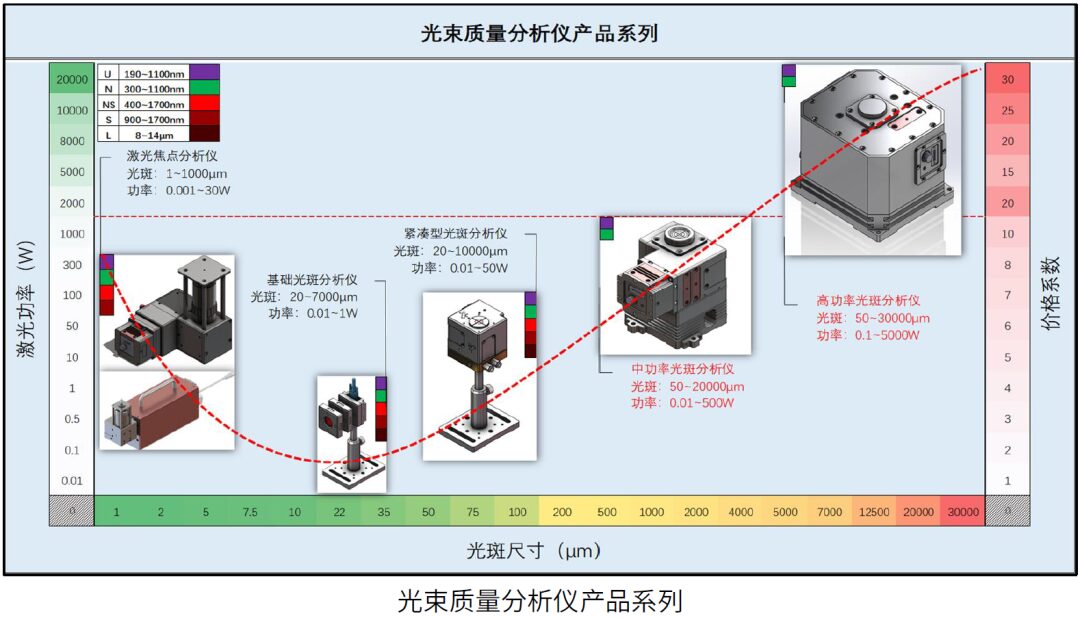

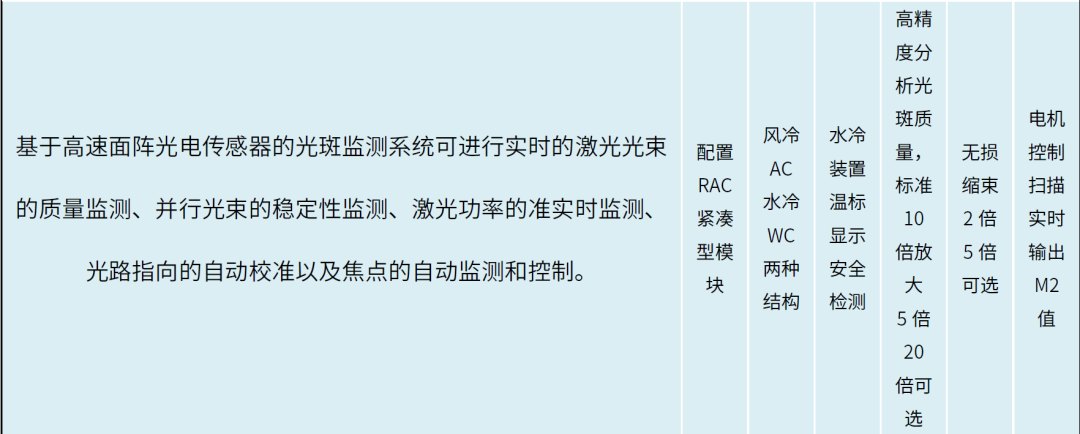

The beam quality analyzer independently developed by Guangyan Technology can achieve laser spot detection and testing applications, providing customers with customized integrated design solutions for beam quality analysis and supporting multi-application development.

It can be modularly customized according to different customer needs, applicable in the fields of semiconductor lasers, solid-state lasers, fiber lasers, ultrafast lasers, and laser ranging. It is currently a mature product promoted in the market, offering a high cost-performance ratio and has been widely recognized by customers in various industries.

(Click to view the full image)

Use Unique Strengths to Satisfy Users

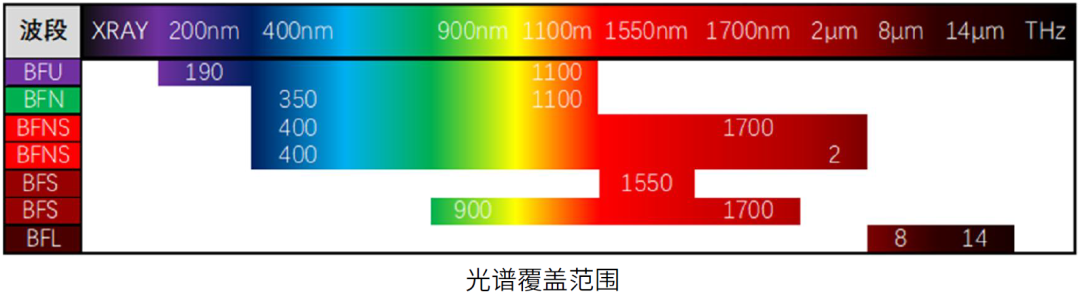

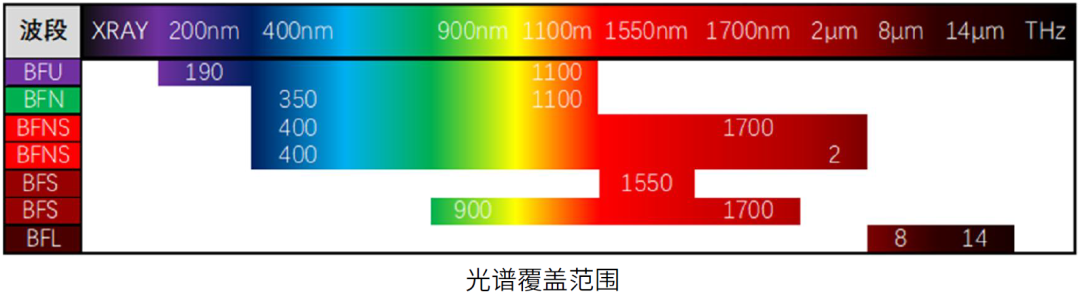

1. A series of ultra-wide spectrum multi-wavelength products are available, covering ultraviolet to long-wave infrared ranges.

2. A wide measurement range for spot diameter: the spot diameter range can meet most of the current market’s spot product range and supports smaller spot expansion.

3. Integrated design of the beam quality analyzer, with matching attenuation scheme design: the device includes an attenuation device, capable of measuring milliwatt-level low-power lasers, and can provide optional attenuation schemes according to different power laser testing needs, allowing for quick measurements without needing additional accessories.

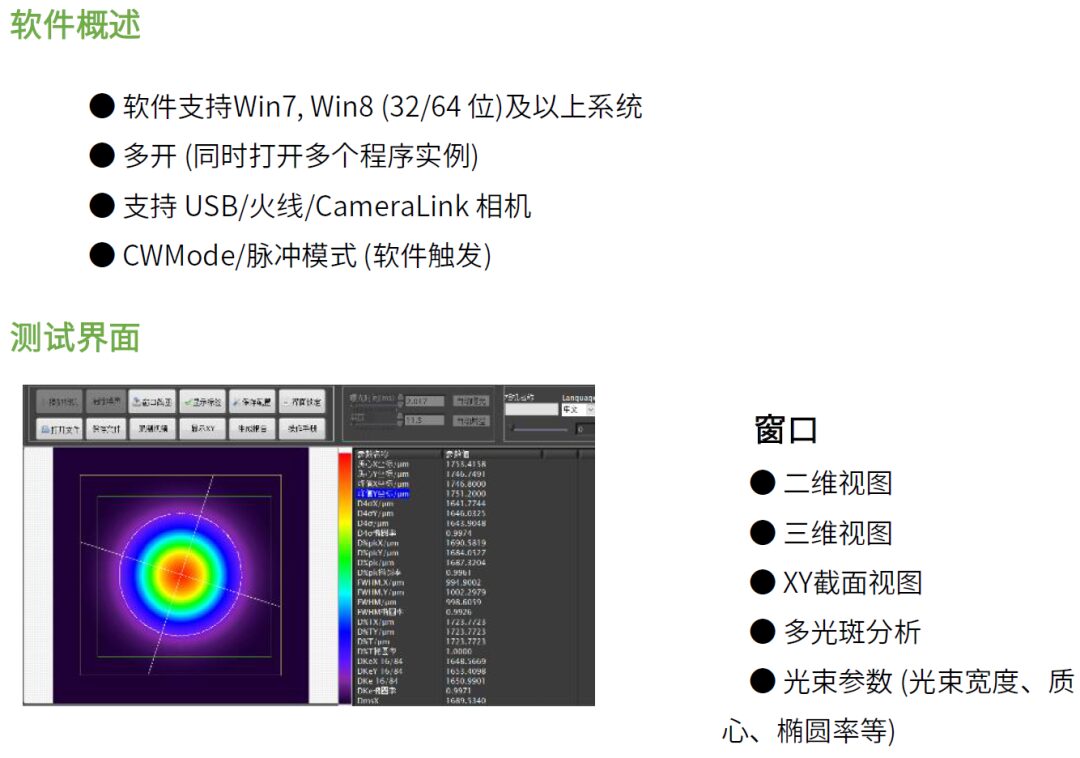

4. Software developed entirely in-house, capable of providing underlying communication protocols.

5. High cost-performance ratio, can replace imported laser beam quality analyzers, achieving laser spot detection and testing applications.

6. Customization on demand: can customize beam quality analyzers according to different customer needs, including different laser beam diameters, laser power, etc.

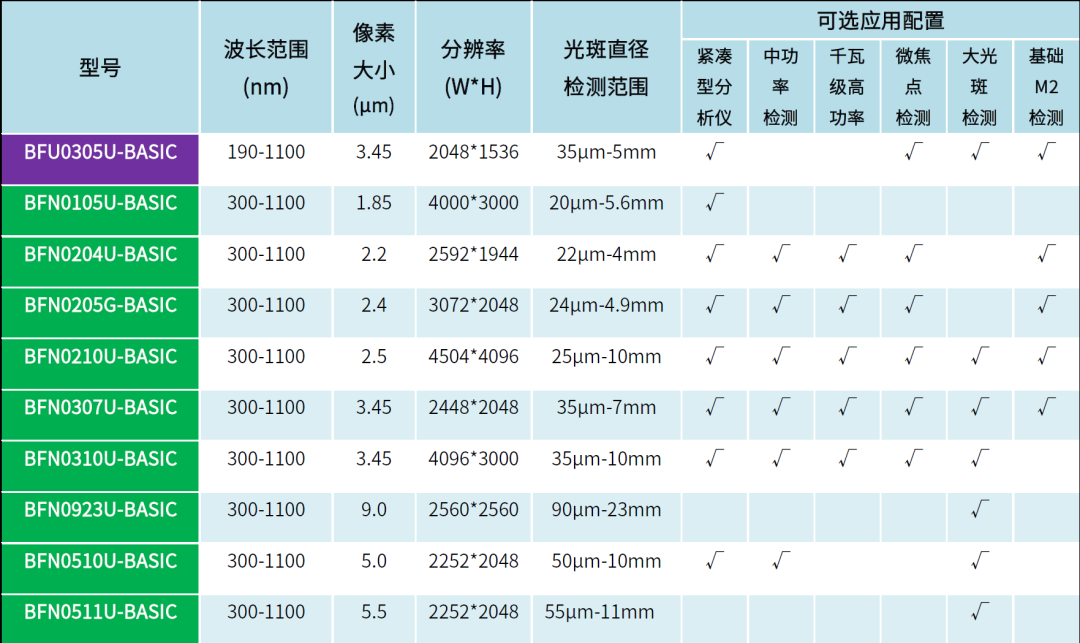

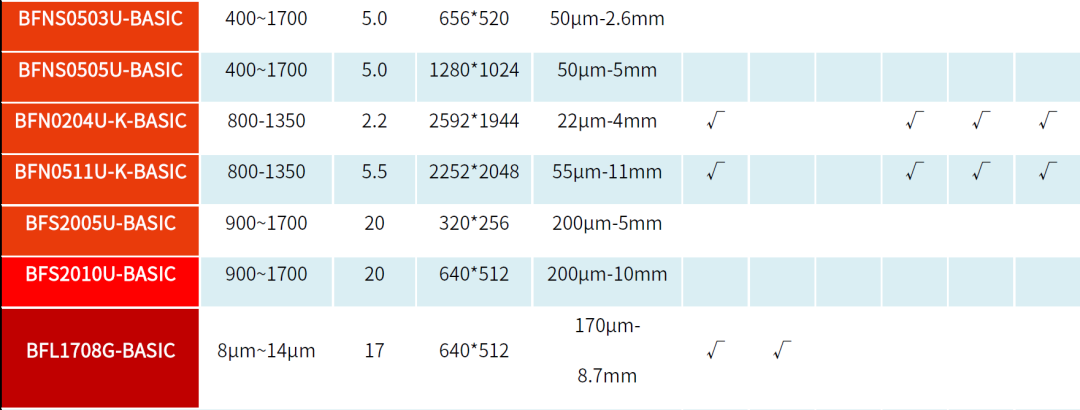

Multiple Models for You to Choose From

(Click to view the full image)

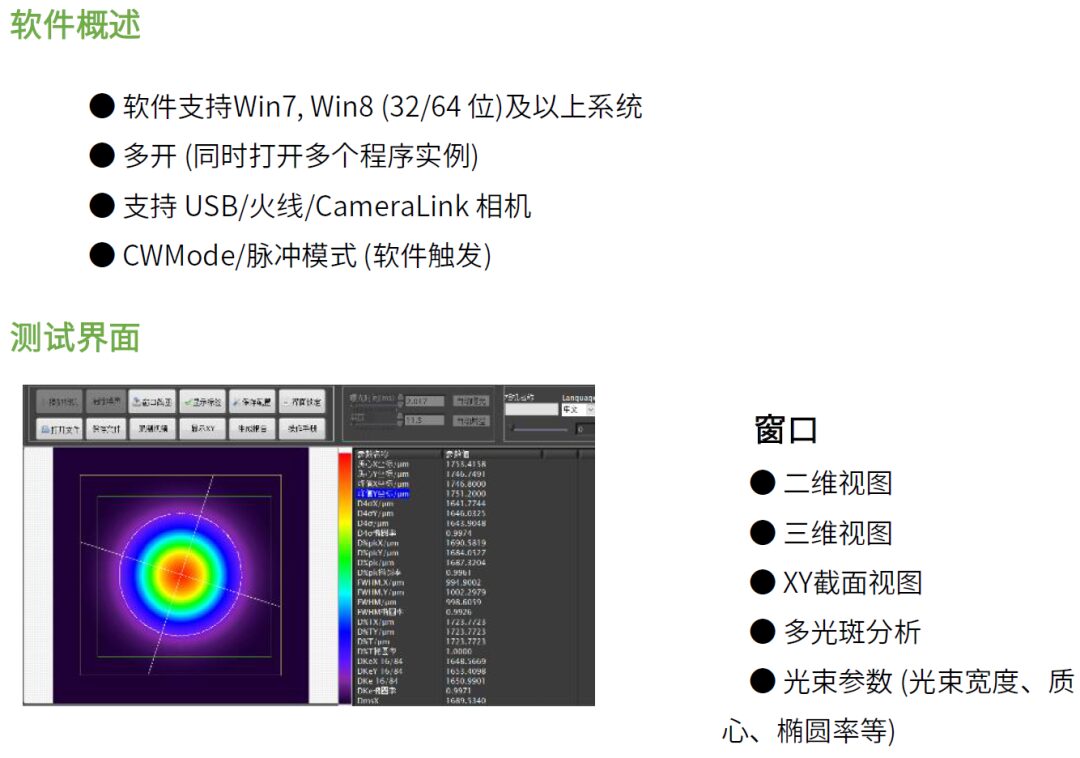

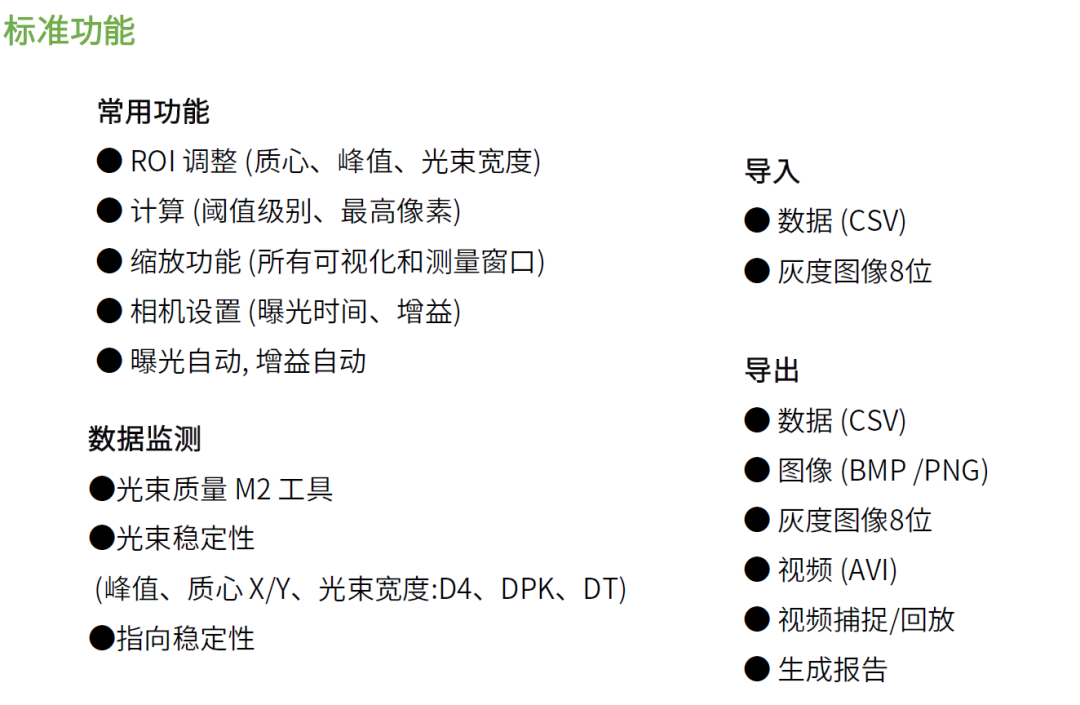

Convenient and Practical Software Design

What are your needs regardingthe Beam Quality Analyzer?Please scan the QR code below

for detailed answers on functions and pricing

Consultation and Ordering Hotline:

15172359028(WeChat same number)

—If you like it, share it with your friends—

Click the “Looking” button in the lower right corner to let more people see it!

Disclaimer: The writing or reprinting of this article is intended to convey more information and contribute to the optoelectronic industry. If any text or images in the article inadvertently infringe upon your legitimate rights or have other improper issues, please contact the author within 20 working days, and we will coordinate to handle it. Friends are welcome to supervise and provide valuable opinions on the content above on the public account!

Contact email: [email protected], industry friends are welcome to invite us to write. Thank you.