Easy Introduction to CANopen Part Five

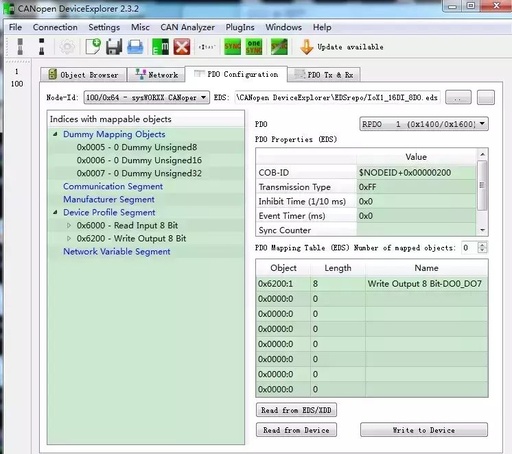

1、Process Data ObjectPDO(Process Data Object) As mentioned earlier PDO belongs to process data used to transmit real-time data, that is, one-way transmission without the need for a response from the receiving nodeCAN message to confirm, from a communication terminology perspective, it belongs to the “producer-consumer” model PDO, as shown in the figure, it is like … Read more