CAN (Controller Area Network) and CANopen are communication protocols commonly used in the automotive and industrial automation fields, facilitating communication between various devices and components within a system.

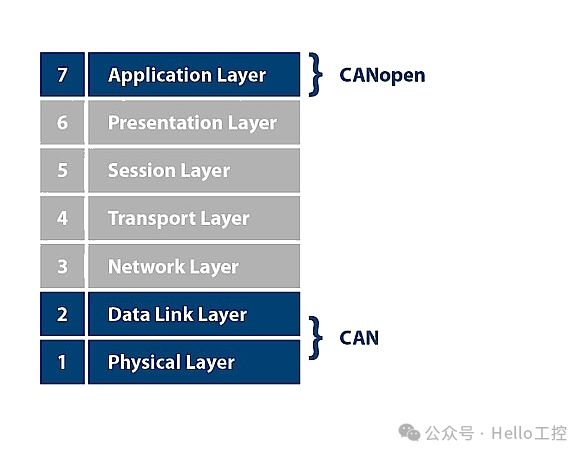

CAN is a serial communication standard that operates at the first two layers of the OSI model, namely the physical layer and the data link layer (functioning at the same level as Ethernet standards but with different functionalities). It defines the data encoding and electrical pulses on two communication lines.

On the other hand, CANopen is a high-level protocol based on CAN, designed for distributed industrial automation technology. It was developed as a standardized deterministic network with high flexibility for configuration, initially designed for motion control systems.

Next, we will compare CAN and CANopen in detail.

What is CAN?

CAN (Controller Area Network):

-

CAN is a robust and widely used communication protocol designed for real-time applications where devices need to communicate with each other over a shared bus.

-

It was originally developed by Robert Bosch GmbH in the 1980s and has since found applications in multiple industries beyond automotive, including industrial automation and aerospace.

-

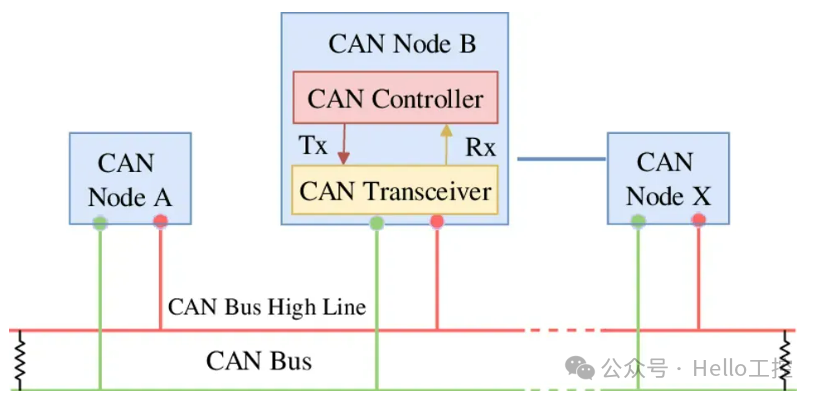

CAN is a two-wire serial communication protocol that uses a differential signaling scheme to transmit and receive data. It provides reliable communication even in noisy environments and is resistant to electrical interference.

-

CAN uses a message-based communication method where nodes (devices or controllers) on the network send messages to each other. These messages can contain data, control commands, or other information.

-

It is a multi-master protocol, meaning any node on the network can transmit data, and the protocol includes a built-in conflict resolution mechanism.

-

CAN is characterized by its high data transmission rate, deterministic communication (consistent and predictable timing), and error detection and correction mechanisms.

What is CANopen?

CANopen:

-

CANopen is a higher-level communication protocol and device configuration profile specification built on the CAN protocol.

-

It standardizes the communication and application layer protocols for devices and systems using CAN as the physical layer.

-

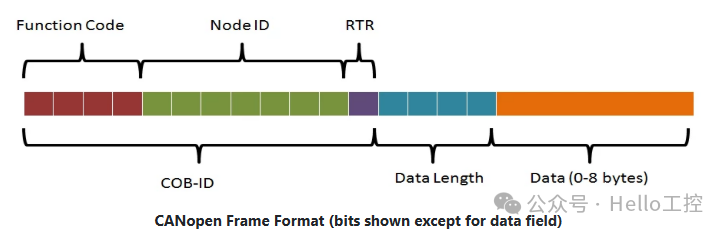

CANopen defines a set of communication services and objects with specific functionalities. These services and objects enable devices on the CANopen network to exchange data and commands seamlessly.

-

CANopen is widely used in industrial automation, machine control, and other applications requiring interoperability and standardization. It simplifies device integration and system development.

-

CANopen allows a wide range of devices to interconnect within the network, including sensors, actuators, and motor controllers. Each device follows a specific device configuration profile, ensuring they understand and respond to the same set of messages and commands.

Differences Between CAN and CANopen

The table below highlights the fundamental differences between CAN and CANopen, with CAN providing a lower-level communication framework, while CANopen standardizes higher-level communication and device interoperability on top of CAN.

| Parameter | CAN | CANopen |

|---|---|---|

| Operating Protocol Layer | Layer 1 (Physical Layer), Layer 2 (Data Link Layer) | Layer 7, Application Layer |

| Communication Type | Low-level Message Protocol | Higher-level Device Communication |

| Standardization | Only defines Physical and Data Link Layers | Defines Application and Communication Services on top of CAN |

| Purpose | Provides a robust and real-time communication bus | Defines a set of device configuration profiles and services for seamless device integration |

| Message Types | Data Frames and Remote Frames | Object Dictionary, PDOs, SDOs, etc. |

| Message Format | Mainly composed of data and control bits | Composed of objects with data, indexes, and attributes |

| Interoperability | Devices need to follow the CAN protocol for Physical and Data Link Layers | Devices communicate following specific CANopen device configuration profiles |

| References | ISO 11898-1, 11898-2, ISO 16845, ISO 16840 | CiA 303-1, 303-2, 303-3 |

| Device Integration | Requires more custom configuration for each application | Simplifies device integration and ensures consistent communication between devices |

| Applications | Used across various industries including automotive, aerospace, and industrial automation | Mainly used for device interoperability in industrial automation |

Conclusion: CAN provides the lower-level communication protocol for the physical and data link layers, while CANopen is a higher-level protocol that standardizes the way devices communicate on the CAN network. CANopen is particularly valuable in complex systems where various devices and components need to work together seamlessly, providing a standardized way to ensure interoperability.

Reference Links:

-

https://www.ni.com/en/shop/seamlessly-connect-to-third-party-devices-and-supervisory-system/the-basics-of-canopen.html

-

https://devicebase.net/en/can-in-automation-canopen/questions/what-is-the-difference-between-can-and-canopen/5hd

-

https://www.rfwireless-world.com/Terminology/Difference-between-CAN-and-CANopen.html

-

[Video Course] Codesys V3.5 Series Introduction Course(134 people have learned) -

[Video Course] Codesys SoftMotion Basic Course(39 people have learned) -

[Video Course] Codesys SoftMotion Electronic Gear Course(12 people have learned) -

[Video Course] Codesys SoftMotion Electronic Cam Course(9 people have learned) -

[Video Course] Codesys Library Custom Library Creation(22 people have learned) -

Comprehensive Free Resource Compilation for Codesys V3.5 Series

-

Top Ten Common Filtering Algorithms (ST Language)

-

What Does a PLC Integrated with Chat GPT Look Like?

-

2023 Annual Top 10 PLC Programming Books Sharing

-

Customize Your Own CODESYS Motion Controller

-

MC_Power.status = FALSE, Can the Axis Move?

-

ST Language Learning Resource Compilation

——–END——–

If you like this article, please share and “like” it below.