In today’s rapidly advancing technology, 3D printers have begun to appear across various industries due to their powerful functionality and wide applicability, providing great convenience for our lives or manufacturing. You are likely to see 3D printers in makerspaces, design studios, and even in school classrooms. One day, your child might come home asking for a 3D printer. So, what exactly is a 3D printer? Some friends who are new to this may not fully understand, so today I will share some knowledge about 3D printers.

A 3D printer (3D Printers), abbreviated as (3DP), is a magical printer designed by an inventor named Enrico Dini, which can not only “print” a complete building but also print other required objects in the shape needed by astronauts in a spacecraft.

3D printers are a type of Rapid Prototyping (RP) technology that creates three-dimensional models layer by layer. The operation process is similar to that of traditional printers, except that traditional printers print ink onto paper to form two-dimensional drawings, while3D printers use materials like liquid photopolymer resin, molten plastic filament, and gypsum powder, which are layered and stacked to form three-dimensional entities through methods such as binder jetting or extrusion.

Classification of 3D Printers

3D printers can be classified intoindustrial 3D printers and desktop 3D printers.

Industrial 3D Printers

Industrial 3D Printers primarily process polymer and metal materials, offering high printing precision and come at a high cost, generally ranging from hundreds of thousands to millions, and even over ten million. Each type of consumable requires a different printer; for instance, to print metal parts, a metal 3D printer must be used.

Desktop 3D Printers

Desktop 3D Printers are compact and can be placed on a desk to print three-dimensional objects. Their prices generally range from a few thousand to tens of thousands, and compared to industrial 3D printers, they have average printing precision and are used for simple mold or model production, mainly for everyday use.

There are many materials for 3D printing today, with the most common beingPLA, ABS, SLA.

PLA Material

PLA is a new type of material made from corn starch, which is a biodegradable and environmentally friendly material, essentially an eco-friendly plastic.

ABS is the common plastic we see, which has a strong odor when printed but is very sturdy.

SLA Liquid Material

SLA is a liquid material that uses the laser head of an SLA 3D printer for printing, offering high precision.

nylon powder

ceramic powder

In addition to the common materials mentioned above, there are also various other consumables such asnylon powder and ceramic powder.

Main Features of 3D Printers

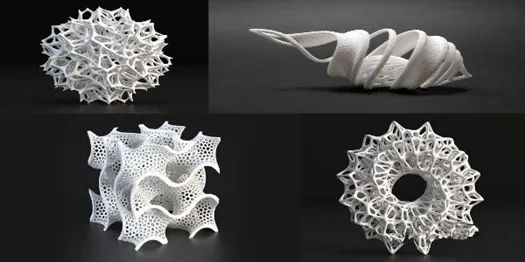

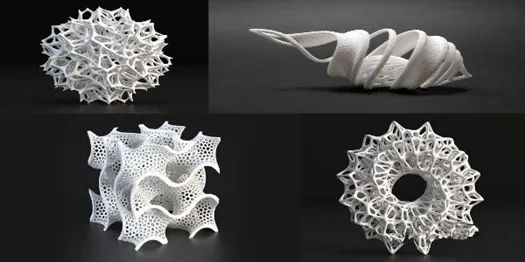

1. Unlimited Design Space

Traditional manufacturing technologies and artisan-made products have limited shapes, and the ability to manufacture shapes is constrained by the tools used. For example, traditional wooden lathes can only produce circular items, rolling mills can only process components assembled with milling cutters, and molding machines can only produce cast shapes. In contrast, 3D printers can break through these limitations, opening up vast design spaces and producing products that are difficult or even impossible to process with traditional methods.

2. Space-Saving and Portable Manufacturing

3D printers can be moved freely and can produce items larger than their own size. For example, injection molding machines can only produce much smaller items, while some 3D printers can produce items much larger than themselves. Additionally, consumer-grade 3D printing devices can be moved freely, and due to their high portability, a number of home or desktop 3D printers have emerged, all thanks to the advantage of requiring less physical space.

3. Material Savings

Traditional metal processing has a significant amount of waste, with some refined productions causing up to 90% of raw materials to be discarded. In contrast, the waste generated by 3D printers will be significantly reduced, and with advances in printing materials, 3D printing “net shaping” manufacturing will become a more environmentally friendly processing method.

4. Shortened Production Time

3D printing can produce items based on people’s needs, and this instant production will greatly reduce inventory levels for companies, allowing them to start 3D printers based on user demand to manufacture customized products to meet customer needs. This new business model will become possible. If the items people need can be produced on-demand and nearby, this production method of zero inventory and zero delivery time can also reduce long-distance transportation costs.

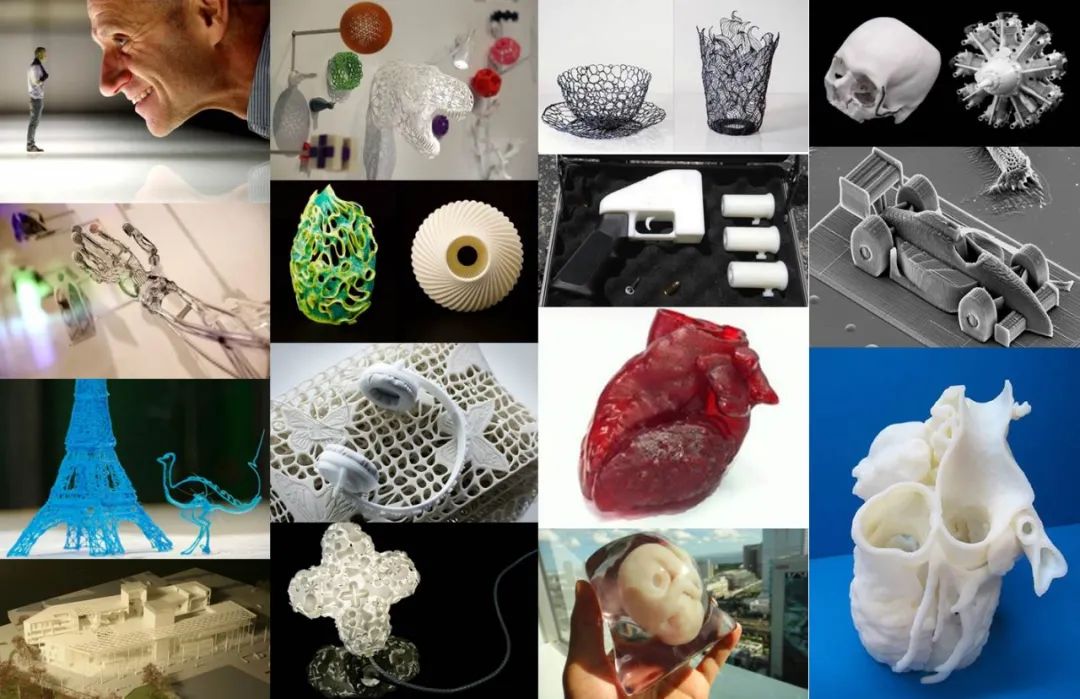

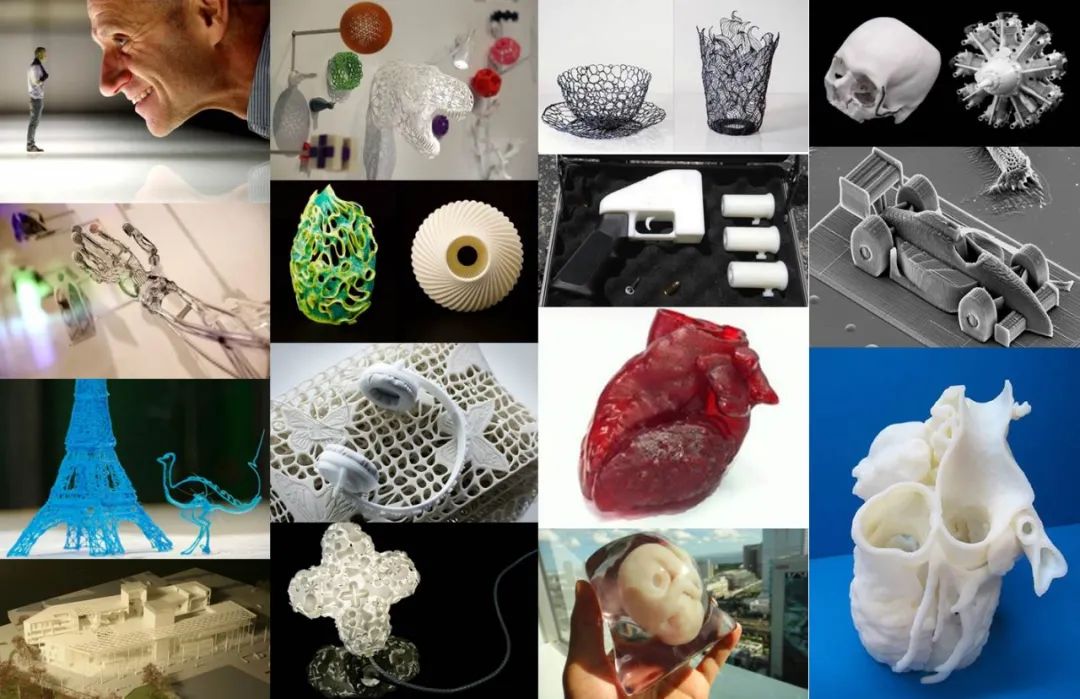

3D printers have a wide range of uses and have been integrated into multiple industries.

(1)Industrial Manufacturing: Product concept design, prototype production, product evaluation, functionality verification; making mold prototypes or directly printing molds, directly printing products.

(2)Cultural Creativity and Digital Entertainment: Complex shapes and structures, special materials for artistic expression carriers. 3D printing is used to shape some characters and props.

(3)Aerospace, Defense, and Military Industry: Direct manufacturing of complex shapes, finely sized parts, and special performance components.

(4)Biomedical: Artificial bones, teeth, hearing aids, prosthetics, etc.

(5)Consumer Goods: Design and manufacture of jewelry, clothing, shoes, toys, and creative DIY works.