3D printing—an innovative manufacturing technology—has permeated more complex and refined fields from its initial applications in manufacturing, such as the production of plastic, metal, and other materials, including biomedicine. This “additive manufacturing” method of 3D printing can layer by layer print any biological tissue or organ required for tissue engineering.

Among various 3D printing technologies, light-cured 3D printing technology has gradually attracted attention due to its main advantages of high precision and fast speed. The working principle of light-cured 3D printing technology is to use a light source (usually a laser or digital light processing projection) to irradiate photosensitive resin, which contains molecules that can be cross-linked and cured through light-induced reactions. When these molecules are exposed to the light source, they rapidly cross-link and solidify, forming a hardened layer; then, the printing platform descends by the thickness of one layer, and another layer of liquid resin is applied, which is again irradiated and cured by the light source. This process is repeated until a complete three-dimensional structure is formed.

High Resolution: For biomedical applications, accurately manufacturing complex microstructures, such as cells and tiny blood vessels, is crucial, and light-cured 3D printing technology precisely meets this need;

Printing Speed: Another advantage of light-cured 3D printing is its printing speed. For example, DLP light-cured 3D printing can cure an entire layer of resin at once, making this rapid printing method have broad application prospects within the medical system.

This issue of EFL provides a comprehensive interpretation of light-cured 3D printing technology, from the diversity and flexibility of material selection to controlling key factors in the printing process, to examples of tissue engineering applications full of future potential. We hope to provide a framework for a comprehensive understanding and application of this technology through systematic and in-depth discussions for your reference and learning!

1. Selection of Light-Cured Materials

In the light-cured 3D printing process,the chemical reaction of the photosensitive resin is a key step. Photosensitive resins typically contain a large number of compounds with double bonds, such as acrylates or methacrylates. When these resins are exposed to light of a specific wavelength (such as ultraviolet light), the double bonds absorb light energy and open up, forming active free radicals. These free radicals further trigger a chain reaction, causing other double bonds to open, forming a large three-dimensional network structure, which is referred to as the curing process.This speed and efficiency of this process determine the effectiveness and performance of 3D printing.

The following are common light-curing crosslinkers used in light-cured biological 3D printing:

1. Poly(ethylene glycol) diacrylate (PEGDA):PEGDA is a commonly used bio-light-curable material due to its good biocompatibility, adjustable mechanical properties (such as strength and flexibility), and adjustable curing speed. This makes PEGDA an ideal material suitable for many different types of biological applications, including 3D printing of biological tissues, drug delivery systems, and cell culture scaffolds. The molecular weight of PEGDA will affect several of its key properties, such as its water solubility, viscosity, crosslinking density, mechanical properties, and biocompatibility with cells. Therefore, selecting the appropriate molecular weight of PEGDA is an important factor in preparing biomedical products through light-cured 3D printing.

2. Gelatin methacryloyl (GelMA):GelMA is a biocompatible material synthesized from gelatin (a natural protein) and methacrylate (a commonly used light-sensitive monomer). In light-cured 3D printing, GelMA is often used to print various types of human tissue models and tissue engineering materials, such as blood vessels, myocardium, skin, bones, liver, etc. In addition, GelMA can also be mixed with other biomaterials to improve printing effects or meet specific application needs. Since GelMA is derived from natural materials, its properties may vary due to differences in sourcing; furthermore, its cured gel is highly sensitive to humidity and temperature, which may affect its stability in certain environments.

3. Hyaluronic acid methacrylate (HAMA):Hyaluronic acid is a naturally occurring polysaccharide present in the connective tissues of all mammals, as well as in the eye and synovial fluid. It has good compatibility with cells and can mimic the natural cellular environment. In HAMA, the carboxyl groups on the hyaluronic acid molecules react with methacrylic acid to form acrylate groups, allowing it to crosslink through light curing to form a stable three-dimensional network. Similar to materials like GelMA and PEGDA, the physicochemical properties of HAMA (such as mechanical properties and degradation rates) can be altered by controlling the degree of crosslinking, providing great flexibility for specific applications.

4. Hydroxyethyl methacrylate (HEMA):HEMA is a water-soluble acrylate with good biocompatibility, but unreacted HEMA monomers can be considered to have certain cytotoxicity. Therefore, when using HEMA for biomedical applications, it is essential to ensure its complete curing to reduce its toxicity.

5. Pluronic F127-Diacrylate (PF127-DA):PF127-DA is a widely used crosslinker in light-cured biological 3D printing, prepared from the commercially available block copolymer Pluronic F127 by grafting acrylate groups. Pluronic F127 is composed of polyethylene oxide and polypropylene oxide, and through modification, PF127-DA carries acrylate functional groups in its polyethylene oxide part. Due to the presence of acrylate, PF127-DA can crosslink through light curing to form a stable three-dimensional structure. This material can be stored in a liquid state at room temperature and cured upon exposure to light when a stable structure is needed, facilitating the printing of complex shapes of biomaterials.

Additionally, many molecules without double bonds can be converted into crosslinkers capable of light polymerization by introducing double bonds, such as acrylates or methacrylates. This method is often used to improve the properties of existing materials or create entirely new materials, such as enhancing their light curing efficiency, improving their biocompatibility, or adjusting their mechanical properties. This is also a commonly used strategy in biological light-cured 3D printing, enabling more customized designs and broader applications.

2. Factors in Light-Cured Printing

In addition to the selection of light-curable crosslinkers, the following key factors must also be considered when selecting light-cured materials:

1. Curing Speed:Determines printing efficiency. Ideal light-cured materials should have a sufficiently fast curing speed to form a stable three-dimensional structure in a short time. However, if the curing speed is too fast, it may lead to loss of detail (overexposure) or deformation. Therefore, selecting materials with appropriate curing speeds is a trade-off, and here are several methods to adjust curing speed:

(1) Adjusting the formulation of photosensitive resin:Photosensitive resins typically contain photoinitiators, which are chemicals that can absorb light energy and initiate curing reactions. The curing speed can be adjusted by increasing or decreasing the amount of photoinitiator or by replacing it with different types of photoinitiators; additionally, adding pigments or other light-absorbing agents can reduce the curing speed.

(2) Using different wavelengths of light:Different photoinitiators react differently to different wavelengths of light; some resins may be more sensitive to specific wavelengths of light, so choosing an appropriate wavelength light source can also affect curing speed.

(3) Changing the intensity of the light source:The greater the intensity of the light source irradiating the photosensitive resin, the faster the photoinitiated reaction usually occurs, and the faster the curing speed. Conversely, if the intensity of the light source is reduced, the curing speed will slow down. Thus, adjusting the intensity of the light source can control the curing speed to some extent.

(4) Changing the irradiation time of the light source:The longer the irradiation time, the deeper the curing extent, and vice versa. Adjusting the irradiation time can also affect the curing speed.

In practical operations, it may be necessary to consider and adjust multiple factors based on specific application requirements and actual conditions.

2. Strength:Determines the durability and functionality of the printed object. Different applications have different strength requirements for materials. For example, materials used for printing parts that must withstand heavy loads or high stress (such as bone or dental tissue engineering materials) need to select materials with high strength, while parts used for decorative or low-stress applications (such as skin) can choose materials with lower strength.

3. Flexibility:Flexibility determines the elasticity and toughness of the printed object. Specific needs must be analyzed; some applications require hard and brittle materials, while others may require flexible materials. For example, materials for manufacturing soft biological tissue models need to have a certain degree of flexibility.

4. Biocompatibility:For biomedical applications, such as 3D printing artificial tissues and organs, biocompatibility is an extremely important factor. The selected light-cured materials must be biocompatible, meaning they do not produce harmful reactions in biological tissues, do not induce adverse immune responses, are non-toxic to cells, and can support cell attachment and growth. Smaller molecules or molecular fragments are more likely to penetrate cell membranes and enter cells. If these small molecules or fragments are toxic or can induce cellular stress responses, they may trigger inflammation or other adverse reactions. Materials used in 3D printing or other biomedical applications typically require a certain degree of stability to prevent rapid decomposition or release of toxic small molecules under physiological conditions.

5. Other Factors:There are also other factors that may need to be considered, such as material cost, availability, photosensitivity, stability, and environmental impact.

Choosing appropriate light-cured materials is a complex task that requires comprehensive consideration of the above factors and the specific needs of particular applications. In some cases, it may be necessary to meet specific requirements by improving existing materials or developing new materials. Continuous research and development are driving advancements in light-cured material science to meet the demands of light-cured 3D printing in various applications.

3. Applications of Light-Cured 3D Printing in Tissue Engineering

Due to its high precision and flexibility, light-cured 3D printing has become an important technology in the field of tissue engineering. EFL summarizes some major applications of light-cured 3D printing in tissue engineering:

Application 1—Constructing Complex Biological Tissue and Organ Models:Biological tissues often have very complex micro and macro structures. Light-cured 3D printing technology can accurately replicate these structures, thus creating accurate biological tissue models.

Application 2—Customizing Personalized Grafts:By combining medical imaging data (such as CT or MRI scan results) with 3D printing technology, personalized grafts that perfectly match the specific anatomical structures of patients can be manufactured. This technology has been used to create personalized grafts for bones, teeth, and joints.

Application 3—Bioprinting:Bioprinting is a special 3D printing technology that uses biological materials (such as cells and biomolecules) as “ink” to print living biological tissues and organs. Light-cured 3D printing has great potential in this area because it can precisely control the distribution of materials at the cellular level.

Application 4—Constructing Drug Delivery Systems:Light-cured 3D printing can be used to manufacture precise drug delivery systems, such as the structural design of drug carriers. These systems can be used for targeted drug delivery, enhancing drug efficacy while reducing side effects.

Application 5—Printing Cell Scaffolds:This is a three-dimensional microstructure that can provide physical support for cell growth and differentiation. Cell scaffolds play a key role in tissue engineering as they can simulate the natural environment of cells in the body, promoting the formation of new tissues. Based on light-cured 3D printing, extremely fine extracellular matrix structures can be created with very high precision.

Application 6—Manufacturing Flexible Bio-Sensing Circuits:Flexible bio-sensing circuits are typically composed of bendable and stretchable electronic components that can closely integrate with biological tissues to continuously monitor physiological signals in real-time. For example, these devices can be used to monitor electrocardiogram signals, nerve electrical signals, electromyography signals, or physiological chemical parameters such as blood sugar levels and blood oxygen concentrations. Conductive polymers, metal nanowires, and carbon-based materials (such as carbon nanotubes and graphene) can all be designed as photosensitive resins and then accurately printed into the desired circuit structures using light-cured 3D printing technology.

Other Applications:Furthermore, light-cured 3D printing technology can also be used to manufacture flexible bio-batteries, energy harvesters, and bio-electronic skin, among other devices. These devices tightly integrate electronic technology and biotechnology, offering new possibilities for medical, health monitoring, and human-machine interface fields. However, achieving these applications requires solving many scientific and engineering problems, such as how to design and select suitable photosensitive materials, how to ensure the performance and stability of circuits, and how to guarantee biocompatibility and biological stability.

Related Research and Reviews

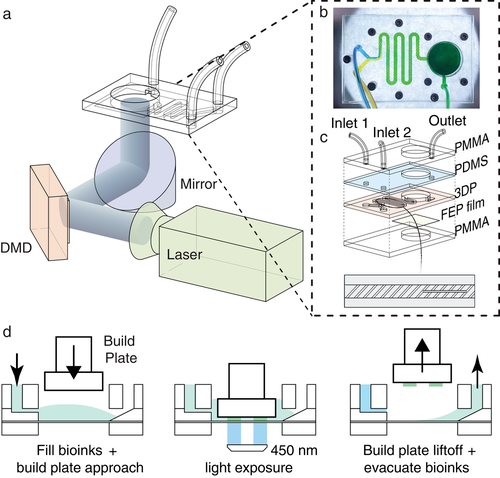

Literature 1: “Adv. Mater.” Bio-printing with Combinable Gradients Based on Digital Light Processing (2021)

Main Content:Reproducing complex tissues poses a huge challenge, and so far, only a few methods can effectively reconstruct the necessary gradients in 3D structures. This paper develops a printing system based on combinable gradient digital light processing, utilizing unprecedented integration of microfluidic mixers to generate continuous or discrete gradients of the required bio-inks in real-time. By adjusting the flow ratio of bio-inks, precise control of gradients can be easily and instantaneously combined. The authors demonstrate various planar and 3D structures exhibiting continuous gradients of materials, cell densities, growth factor concentrations, hydrogel stiffness, and porosity in horizontal and/or vertical directions.

https://doi.org/10.1002/adma.202107038

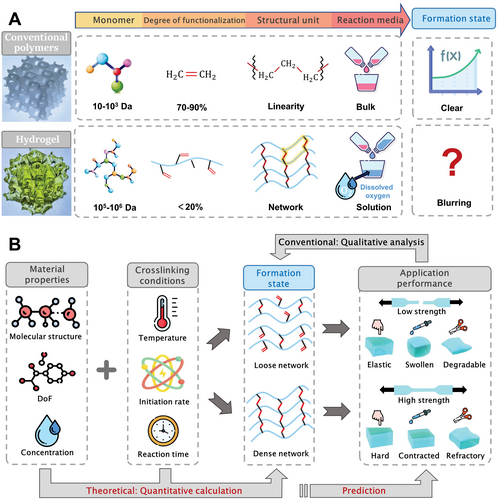

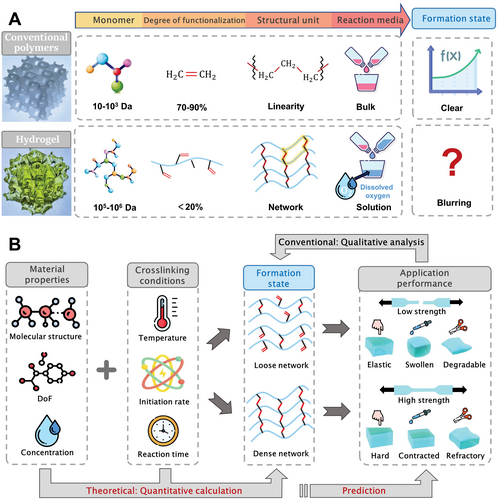

Literature 2: “Adv. Funct. Mater.”: Formation Theory and Printability of Light-Cured Hydrogels for 3D Bioprinting (2023)

Main Content:Due to the good formability and biocompatibility of light-cured biological hydrogels, bio-inks have gradually transitioned from ionic crosslinking to light crosslinking. Understanding and quantifying the crosslinking process of light-cured hydrogels is crucial; otherwise, bioprinting cannot be standardized and scaled. However, few studies on the formation process of hydrogels and their light crosslinking behaviors can accurately predict them. This paper establishes a formation theory using light-induced free radical polymerization of biological hydrogels as an example. The authors propose the concept of Effective Double Bond Conversion (EDBC) and define several important formation indices. According to theoretical predictions, slow crosslinking can enhance crosslinking density. Additionally, based on the slow crosslinking effect, a new strategy for projection-based 3D printing (PBP) is proposed, significantly improving printing quality and efficiency.

https://doi.org/10.1002/adfm.202301209

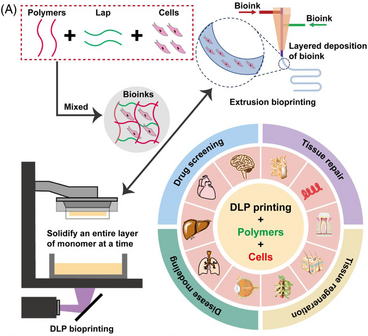

Literature 3: “Aggregate”: (Bio)Printing Strategies for Tissue Modeling and Regeneration Using Digital Light Processing (2022)

Main Content:3D bioprinting can precisely manufacture various 3D high-resolution objects, widely used to create 3D tissue models that simulate human microphysiological environments. Among them, DLP 3D printing technology can design and develop complex tissue scaffolds, encapsulating various stem cells in materials with different stiffness. This paper briefly introduces DLP bioprinting and further discusses the design and manufacturing of DLP (bio) printers with various bio-inks and their biomedical applications in drug screening, disease modeling, tissue repair, and regenerative medicine. Finally, it details the advantages, challenges, and prospects of DLP printing platforms.

https://doi.org/10.1002/agt2.270

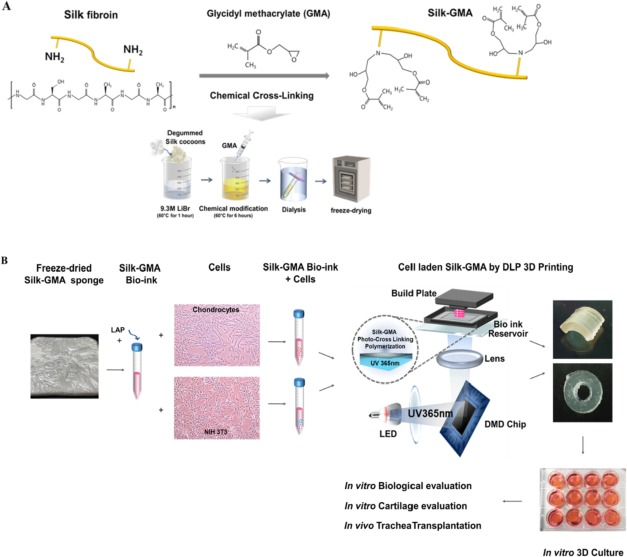

Literature 4: “Biomaterials”: Digital Light Processing 3D Printing Silk Protein Hydrogels for Cartilage Tissue Engineering (2020)

Main Content:Using digital light processing (DLP) printers for 3D printing has become a new wave in regenerative medicine tissue engineering, especially for clinical applications. This study utilizes glycerol-based methacrylate (Silk-GMA) for DLP 3D printing. In vitro culture systems evaluate the cartilage-forming ability of Silk-GMA containing chondrocytes and its in vivo application. Up to 4 weeks of in vitro culture of Silk-GMA hydrogels can ensure cell viability, proliferation, and differentiation into cartilage formation. Animal experiments show that new cartilage-like tissue and epithelium were found around the transplanted Silk-GMA hydrogel.

https://doi.org/10.1016/j.biomaterials.2019.119679

Literature 5: “Biomaterials”: Rapid Printing of Biomimetic 3D Tissue Structures for Skin Regeneration (2020)

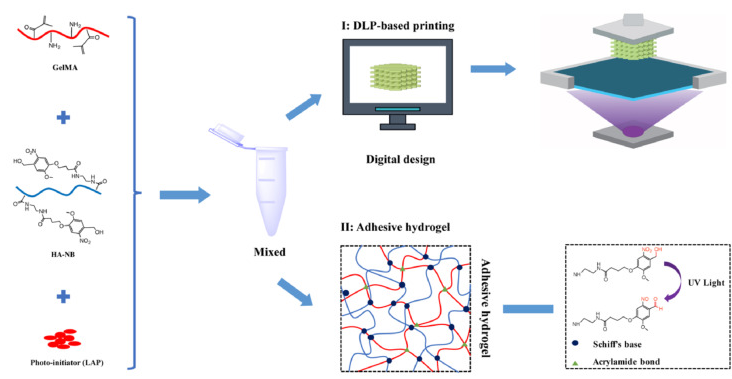

Main Content:For existing bioprinting technologies, manufacturing suitable implanted organs remains a challenge, mainly due to the inability to generalize the complex anatomical structures, mechanical properties, and biological functions of organs. To this end, this study develops a new method for printing functional living skin (FLS) using newly designed biomimetic bio-inks (GelMA/HA-NB/LAP) and DLP-based 3D printing technology. FLS features interconnected microchannels that promote cell migration, proliferation, and new tissue formation. The bio-inks demonstrate rapid gelation kinetics, adjustable mechanical properties, and tissue adhesion. FLS promotes skin regeneration and effective neovascularization by mimicking the physiological structure of natural skin, providing a method for rapid, large-scale production of functional living organs for future clinical applications.

https://doi.org/10.1016/j.biomaterials.2020.120287

Light-cured 3D printing, as a new type of biological manufacturing technology, is changing the future of the tissue engineering field. The core of this technology lies in the rapid transition of light-cured materials from liquid to solid shapes under light irradiation, allowing us to construct complex biological tissue structures with unprecedented precision and speed. This article provides a detailed introduction to commonly used light-cured materials, such as PEGDA, GelMA, HAMA, HEMA, and PF127-DA, which offer a wide range of choices for tissue engineering due to their good biocompatibility, adjustable mechanical properties, and flexible chemical modification possibilities. Additionally, we introduce how to select and optimize these materials based on different biological application needs.

Although light-cured 3D printing shows great potential in tissue engineering, its development still faces many challenges. First, how to further improve printing precision to better replicate the microstructures of biological tissues is an important technical challenge. Second, maintaining and enhancing the biological activity of printed tissues to ensure their functional performance after implantation requires more in-depth research in material design, printing processes, and post-processing. Furthermore, potential byproducts generated during the light curing process, such as unreacted monomers and photoinitiators, as well as temperature increases and dehydration issues that may occur during curing, also need to be further addressed.

It is foreseeable that light-cured 3D printing has the potential to enable the manufacturing of a broader range of biological tissues, including complex multicellular tissues, pathological models, and even complete organs. This not only requires continuous improvement and development of new light-cured materials but also necessitates in-depth exploration in printing equipment, control strategies, and interdisciplinary research related to biology and medicine.

https://doi.org/10.1002/adfm.202301209

Literature 3: “Aggregate”: (Bio)Printing Strategies for Tissue Modeling and Regeneration Using Digital Light Processing (2022)

Main Content:3D bioprinting can precisely manufacture various 3D high-resolution objects, widely used to create 3D tissue models that simulate human microphysiological environments. Among them, DLP 3D printing technology can design and develop complex tissue scaffolds, encapsulating various stem cells in materials with different stiffness. This paper briefly introduces DLP bioprinting and further discusses the design and manufacturing of DLP (bio) printers with various bio-inks and their biomedical applications in drug screening, disease modeling, tissue repair, and regenerative medicine. Finally, it details the advantages, challenges, and prospects of DLP printing platforms.

https://doi.org/10.1002/agt2.270

Literature 4: “Biomaterials”: Digital Light Processing 3D Printing Silk Protein Hydrogels for Cartilage Tissue Engineering (2020)

Main Content:Using digital light processing (DLP) printers for 3D printing has become a new wave in regenerative medicine tissue engineering, especially for clinical applications. This study utilizes glycerol-based methacrylate (Silk-GMA) for DLP 3D printing. In vitro culture systems evaluate the cartilage-forming ability of Silk-GMA containing chondrocytes and its in vivo application. Up to 4 weeks of in vitro culture of Silk-GMA hydrogels can ensure cell viability, proliferation, and differentiation into cartilage formation. Animal experiments show that new cartilage-like tissue and epithelium were found around the transplanted Silk-GMA hydrogel.

https://doi.org/10.1016/j.biomaterials.2019.119679

Literature 5: “Biomaterials”: Rapid Printing of Biomimetic 3D Tissue Structures for Skin Regeneration (2020)

Main Content:For existing bioprinting technologies, manufacturing suitable implanted organs remains a challenge, mainly due to the inability to generalize the complex anatomical structures, mechanical properties, and biological functions of organs. To this end, this study develops a new method for printing functional living skin (FLS) using newly designed biomimetic bio-inks (GelMA/HA-NB/LAP) and DLP-based 3D printing technology. FLS features interconnected microchannels that promote cell migration, proliferation, and new tissue formation. The bio-inks demonstrate rapid gelation kinetics, adjustable mechanical properties, and tissue adhesion. FLS promotes skin regeneration and effective neovascularization by mimicking the physiological structure of natural skin, providing a method for rapid, large-scale production of functional living organs for future clinical applications.

https://doi.org/10.1016/j.biomaterials.2020.120287

Light-cured 3D printing, as a new type of biological manufacturing technology, is changing the future of the tissue engineering field. The core of this technology lies in the rapid transition of light-cured materials from liquid to solid shapes under light irradiation, allowing us to construct complex biological tissue structures with unprecedented precision and speed. This article provides a detailed introduction to commonly used light-cured materials, such as PEGDA, GelMA, HAMA, HEMA, and PF127-DA, which offer a wide range of choices for tissue engineering due to their good biocompatibility, adjustable mechanical properties, and flexible chemical modification possibilities. Additionally, we introduce how to select and optimize these materials based on different biological application needs.

Although light-cured 3D printing shows great potential in tissue engineering, its development still faces many challenges. First, how to further improve printing precision to better replicate the microstructures of biological tissues is an important technical challenge. Second, maintaining and enhancing the biological activity of printed tissues to ensure their functional performance after implantation requires more in-depth research in material design, printing processes, and post-processing. Furthermore, potential byproducts generated during the light curing process, such as unreacted monomers and photoinitiators, as well as temperature increases and dehydration issues that may occur during curing, also need to be further addressed.

It is foreseeable that light-cured 3D printing has the potential to enable the manufacturing of a broader range of biological tissues, including complex multicellular tissues, pathological models, and even complete organs. This not only requires continuous improvement and development of new light-cured materials but also necessitates in-depth exploration in printing equipment, control strategies, and interdisciplinary research related to biology and medicine.

Join the Discussion

Regarding the research direction of regenerative medicine, EFL has established an “Academic Exchange Group” on its official account. Scan the QR code below to add the editor’s WeChat to join the group for discussions~