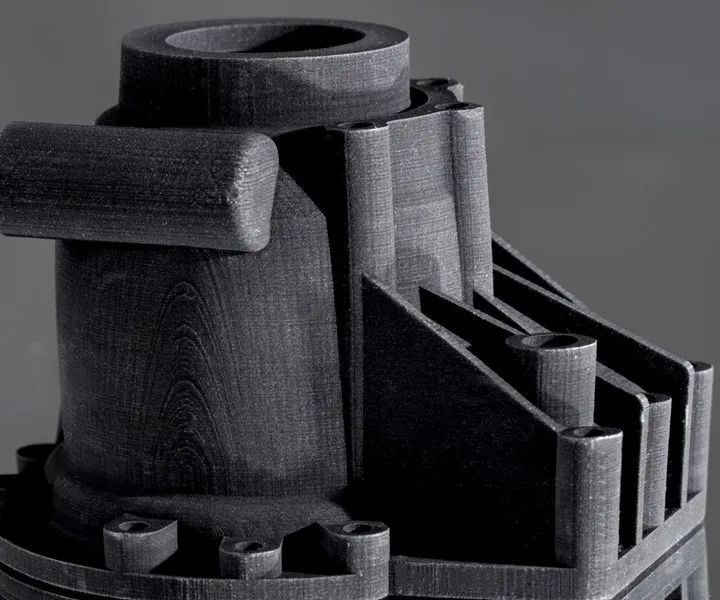

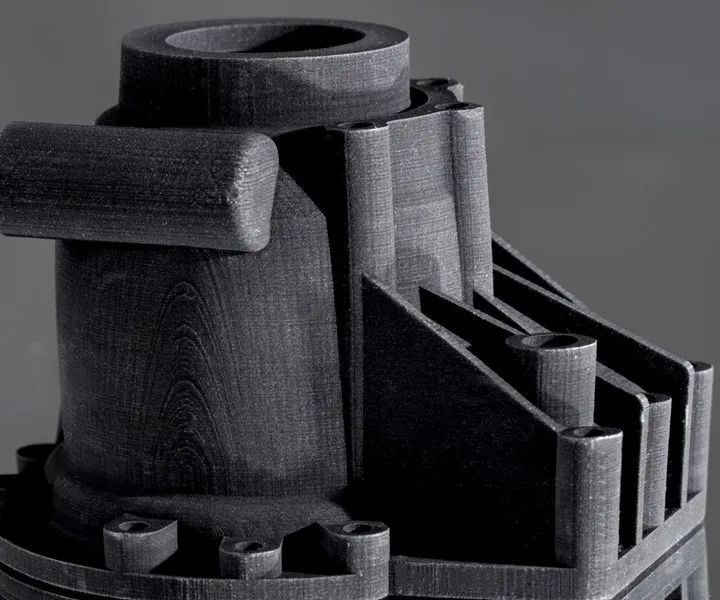

Additive Manufacturing (AM) refers to the process of creating parts or objects based on three-dimensional model data through material accumulation. 3D printing is the process of creating parts or objects through material accumulation using a print head, nozzle, or other printing technologies; this term is often used synonymously with additive manufacturing, hence it is also called ‘3D printing’.

△ 3D printed nozzle made of titanium

Its manufacturing form is generally based on layer-by-layer deposition to construct components. Meanwhile, internationally, ISO/ASTM recognizes seven different types of additive manufacturing technologies:1. Photopolymerization – UV light selectively cures liquid resin point by point or layer by layer;2. Powder Bed Fusion (PBF) – uses an energy source (usually a laser or electron beam) to fuse powdered metals or polymers together;3. Binder Jetting – a binder deposited on metal powder or sand forms geometries; for metals, sintering is usually required after printing to melt the powder;4. Material Jetting – droplets of material are precisely deposited to build a geometry;5. Sheet Lamination – materials are stacked and laminated together through ultrasonic welding, brazing, adhesives, or chemical means;6. Material Extrusion – materials such as polymer filaments or granules are heated and extruded through a nozzle;7. Directed Energy Deposition (DED) – metal powder or wire is fed into a melt pool created by a laser or electron beam, a process similar to welding.Additionally, ‘Hybrid Manufacturing’ describes a process that combines additive manufacturing with traditional subtractive techniques. For instance, a CNC machine can be equipped with a DED print head, allowing the same machine to both 3D print materials and perform milling.At the same time, it is particularly important to emphasize that each of these seven categories has different subcategories of 3D printing. For example, Directed Energy Deposition (DED) can use powder or wire for manufacturing metal parts. Photopolymerization includes categories such as Stereolithography (SLA) and Digital Light Processing (DLP), where SLA is point scanning while DLP cures a layer at once.Machine manufacturers may also have proprietary processes or use different terminologies; the following includes some special types of technology outside these 7 categories of 3D printing processes.

△ Digital Light Synthesis (DLS) is a resin-based 3D printing process

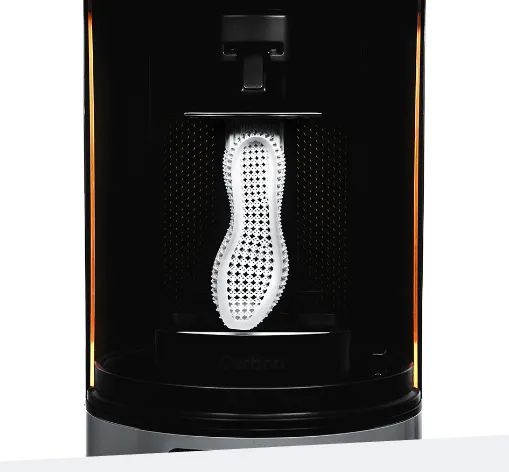

1. Digital Light Synthesis (DLS)Digital Light Synthesis (DLS) is a proprietary 3D printing process based on resin developed by Carbon.How does DLS work?Digital Light Synthesis is based on stereolithography. Both processes use UV light to cure resin. However, unlike stereolithography, Carbon’s process does not pause after each layer. The resin continuously flows over a ‘dead zone’ above an oxygen-permeable membrane, where a UV image of the part’s cross-section is projected onto the oxygen-permeable window to cure the resin. As the build platform rises from the resin vat, the part is inverted.What materials can be used?Carbon’s DLS resins include elastomers, flexible, rigid, and medical-grade polyurethanes, silicones, cyanate esters, epoxies, polyurethane methacrylates, and dental materials.

△ Carbon’s Digital Light Synthesis 3D printing process

What post-processing is required?After printing, the parts are removed from the build plate, and all supports are removed. Some materials also need to undergo thermal curing in an oven, which may take 4 to 13 hours to complete. The heat triggers secondary chemical reactions that enhance the strength of the parts, and no further post-processing is needed after cleaning and curing.Why use DLS?Carbon’s DLS 3D printing process’s continuity avoids the formation of layer lines in the parts, thereby providing a surface finish comparable to injection-molded parts. DLS parts are said to be waterproof and isotropic, having the same strength in all directions. Besides providing a method for prototyping, it can also serve as an alternative for manufacturing production parts.2. NanoParticle Jetting (NPJ)NanoParticle Jetting (NPJ) is a 3D printing process developed by XJet. It is a material jetting technology that uses a suspension of powdered materials to build parts.How does NPJ work?NPJ jets a liquid containing suspended metal or ceramic nanoparticles to build parts while simultaneously jetting a support material. The forming process occurs on a heated bed at 250°C, causing the liquid to evaporate during jetting, allowing the particles to adhere in all directions, with only a small amount of adhesive in the printed 3D object body and support.What materials can be used?Xjet supports the use of 316L stainless steel and two ceramic materials (zirconia and alumina) for NanoParticle Jetting. The materials are installed in the machine via cartridges and do not require processing or handling.

△ Digital Light Synthesis (DLS) is a resin-based 3D printing process

1. Digital Light Synthesis (DLS)Digital Light Synthesis (DLS) is a proprietary 3D printing process based on resin developed by Carbon.How does DLS work?Digital Light Synthesis is based on stereolithography. Both processes use UV light to cure resin. However, unlike stereolithography, Carbon’s process does not pause after each layer. The resin continuously flows over a ‘dead zone’ above an oxygen-permeable membrane, where a UV image of the part’s cross-section is projected onto the oxygen-permeable window to cure the resin. As the build platform rises from the resin vat, the part is inverted.What materials can be used?Carbon’s DLS resins include elastomers, flexible, rigid, and medical-grade polyurethanes, silicones, cyanate esters, epoxies, polyurethane methacrylates, and dental materials.

△ Carbon’s Digital Light Synthesis 3D printing process

What post-processing is required?After printing, the parts are removed from the build plate, and all supports are removed. Some materials also need to undergo thermal curing in an oven, which may take 4 to 13 hours to complete. The heat triggers secondary chemical reactions that enhance the strength of the parts, and no further post-processing is needed after cleaning and curing.Why use DLS?Carbon’s DLS 3D printing process’s continuity avoids the formation of layer lines in the parts, thereby providing a surface finish comparable to injection-molded parts. DLS parts are said to be waterproof and isotropic, having the same strength in all directions. Besides providing a method for prototyping, it can also serve as an alternative for manufacturing production parts.2. NanoParticle Jetting (NPJ)NanoParticle Jetting (NPJ) is a 3D printing process developed by XJet. It is a material jetting technology that uses a suspension of powdered materials to build parts.How does NPJ work?NPJ jets a liquid containing suspended metal or ceramic nanoparticles to build parts while simultaneously jetting a support material. The forming process occurs on a heated bed at 250°C, causing the liquid to evaporate during jetting, allowing the particles to adhere in all directions, with only a small amount of adhesive in the printed 3D object body and support.What materials can be used?Xjet supports the use of 316L stainless steel and two ceramic materials (zirconia and alumina) for NanoParticle Jetting. The materials are installed in the machine via cartridges and do not require processing or handling.

△ Ceramic components manufactured using NanoParticle Jetting technology

What post-processing is required?After printing, NPJ parts still retain a small amount of adhesive and may have support structures. The carrier material is water-soluble and can dissolve in a water bath. If necessary, machining or polishing can be done at this stage.

△ An example of a part manufactured through NPJ, with its soluble support material still intact

Why use NanoParticle Jetting?This process allows for the simultaneous manufacturing of many small parts. According to XJet, the material jetting process can be controlled drop by drop, with a range of ±25 microns for small parts and ±50 microns for larger MIM/CIM parts. The minimum feature size is 100 microns, and the layer height can be 8 to 10 microns, allowing for refined details.Since NPJ uses suspended materials, there is no need for screening and other steps required for powder processes. Materials can be printed in normal atmosphere without special gases, vacuum, or pressure, and they are easy to recycle.Applications of NanoParticle Jetting include hearing aids in the medical industry, surgical tools, dental crowns, dental bridges, and guide drills; high-temperature and wear-resistant parts for aerospace and automotive; and sensors for the electrical industry.3. Ultrasonic Additive Manufacturing (UAM)This process is developed by Fabrisonic and manufactures metal workpieces by fusing and stacking metal strips. This work is done on a hybrid machine tool capable of CNC milling of the workpiece as additive manufacturing proceeds. By stacking metal strips for construction, rapid build speeds can make large parts practical.

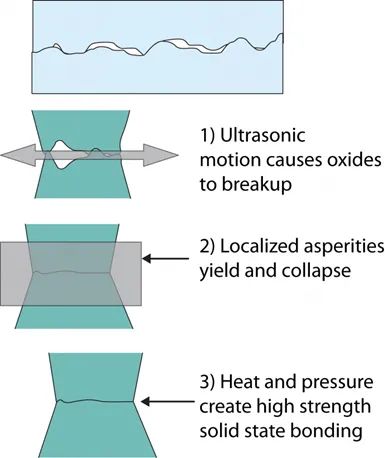

How does UAM work? In UAM, materials are not melted but are joined through ultrasonic welding. This welding uses high-frequency vibrations to connect surfaces while keeping the metal solid. By welding layer by layer in this manner, strong parts are constructed.

△ This solid-state additive process allows parts to be produced from different metals

Under high-frequency ultrasonic vibrations and constant pressure, ultrasonic motion breaks down oxides, allowing direct contact between metals.

△ This process forms solid atomic bonds or welds between thin metal strips and substrates with minimal heating, welding multiple layers together to increase height

Repeat this process until a solid part is built. CNC contour milling can then be used to achieve the desired tolerances and optimal surface finish of the parts.Why use Ultrasonic Additive Manufacturing?Hard metal outer surfaces can be built on structures made of lighter metals to provide durability and lightweight parts. Alternatively, two distinctly different metals – such as titanium and aluminum can be combined into hybrid layers, forming a structure that combines the properties of both.This technology combines the practicality of additive and subtractive manufacturing, allowing for parts with complex geometries and internal channels to be manufactured. The fine dimensional accuracy and smooth surfaces of parts made using UAM and machining demonstrate the possibilities of hybrid manufacturing.4. Selective Thermoplastic Electrophotography (STEP)Developed by Evolve Additive Solutions, the Selective Thermoplastic Electrophotography (STEP) technology combines 2D imaging with proprietary IP to precisely align incoming layers and bond them into fully dense final parts, whose isotropic properties are said to equal or exceed those of injection molding.

△ Ceramic components manufactured using NanoParticle Jetting technology

What post-processing is required?After printing, NPJ parts still retain a small amount of adhesive and may have support structures. The carrier material is water-soluble and can dissolve in a water bath. If necessary, machining or polishing can be done at this stage.

△ An example of a part manufactured through NPJ, with its soluble support material still intact

Why use NanoParticle Jetting?This process allows for the simultaneous manufacturing of many small parts. According to XJet, the material jetting process can be controlled drop by drop, with a range of ±25 microns for small parts and ±50 microns for larger MIM/CIM parts. The minimum feature size is 100 microns, and the layer height can be 8 to 10 microns, allowing for refined details.Since NPJ uses suspended materials, there is no need for screening and other steps required for powder processes. Materials can be printed in normal atmosphere without special gases, vacuum, or pressure, and they are easy to recycle.Applications of NanoParticle Jetting include hearing aids in the medical industry, surgical tools, dental crowns, dental bridges, and guide drills; high-temperature and wear-resistant parts for aerospace and automotive; and sensors for the electrical industry.3. Ultrasonic Additive Manufacturing (UAM)This process is developed by Fabrisonic and manufactures metal workpieces by fusing and stacking metal strips. This work is done on a hybrid machine tool capable of CNC milling of the workpiece as additive manufacturing proceeds. By stacking metal strips for construction, rapid build speeds can make large parts practical.

How does UAM work? In UAM, materials are not melted but are joined through ultrasonic welding. This welding uses high-frequency vibrations to connect surfaces while keeping the metal solid. By welding layer by layer in this manner, strong parts are constructed.

△ This solid-state additive process allows parts to be produced from different metals

Under high-frequency ultrasonic vibrations and constant pressure, ultrasonic motion breaks down oxides, allowing direct contact between metals.

△ This process forms solid atomic bonds or welds between thin metal strips and substrates with minimal heating, welding multiple layers together to increase height

Repeat this process until a solid part is built. CNC contour milling can then be used to achieve the desired tolerances and optimal surface finish of the parts.Why use Ultrasonic Additive Manufacturing?Hard metal outer surfaces can be built on structures made of lighter metals to provide durability and lightweight parts. Alternatively, two distinctly different metals – such as titanium and aluminum can be combined into hybrid layers, forming a structure that combines the properties of both.This technology combines the practicality of additive and subtractive manufacturing, allowing for parts with complex geometries and internal channels to be manufactured. The fine dimensional accuracy and smooth surfaces of parts made using UAM and machining demonstrate the possibilities of hybrid manufacturing.4. Selective Thermoplastic Electrophotography (STEP)Developed by Evolve Additive Solutions, the Selective Thermoplastic Electrophotography (STEP) technology combines 2D imaging with proprietary IP to precisely align incoming layers and bond them into fully dense final parts, whose isotropic properties are said to equal or exceed those of injection molding.

△ STEP is designed for high-speed, large-scale additive manufacturing and factory workshop integration

What materials can be used?The company states that the candidate materials for STEP are the same as those used for injection molding polymers. However, providing materials as carbon powder requires Evolve’s proprietary material engineering technology.STEP machines have multiple print heads, allowing for multiple colors in parts, but another possibility is the potential for multiple materials. Various different polymers applied at the voxel level can achieve performance combinations not obtainable in any single material.Why use STEP?STEP provides a method to obtain thousands of plastic parts within days, whereas waiting for mold processing can take weeks for delivery. Moreover, since there are no molds, the unit cost of new technologies at this quantity level is also lower than molding.This process can produce parts without layer lines, as STEP matches heated layers with heated components, resulting in a more complete fusion than processes like FDM.5. Multi Jet Fusion (MJF)This process is a powder bed 3D printing process developed by HP, which binds reagents and powders together in a manner similar to binder jetting. Unlike powder bed fusion systems based on point-to-point lasers, MJF selectively distributes fusion agents and detailing agents across the powder bed and uses infrared light to fuse the layers together.

△ STEP is designed for high-speed, large-scale additive manufacturing and factory workshop integration

What materials can be used?The company states that the candidate materials for STEP are the same as those used for injection molding polymers. However, providing materials as carbon powder requires Evolve’s proprietary material engineering technology.STEP machines have multiple print heads, allowing for multiple colors in parts, but another possibility is the potential for multiple materials. Various different polymers applied at the voxel level can achieve performance combinations not obtainable in any single material.Why use STEP?STEP provides a method to obtain thousands of plastic parts within days, whereas waiting for mold processing can take weeks for delivery. Moreover, since there are no molds, the unit cost of new technologies at this quantity level is also lower than molding.This process can produce parts without layer lines, as STEP matches heated layers with heated components, resulting in a more complete fusion than processes like FDM.5. Multi Jet Fusion (MJF)This process is a powder bed 3D printing process developed by HP, which binds reagents and powders together in a manner similar to binder jetting. Unlike powder bed fusion systems based on point-to-point lasers, MJF selectively distributes fusion agents and detailing agents across the powder bed and uses infrared light to fuse the layers together.

△ These sample parts manufactured through Multi Jet Fusion illustrate the design freedom of the process and the potential variety of parts that can constitute a single build. As the printing process does not require support structures, parts can be nested and stacked to fill the entire build volume

The Multi Jet Fusion system consists of replaceable build units that can be moved between MJF 3D printers and separate post-processing stations for rapid cooling and powder removal. This modular system allows printers and post-processing stations to run continuously while build units circulate through, speeding up part production.

△ Periscope housing manufactured on HP’s Multi Jet Fusion 3D printing platform

What post-processing is required?After the build is complete, the build unit (the entire powder bed with encapsulated parts) is removed from the printer and placed in a post-processing unit for rapid cooling. The build unit is then moved to a processing station, where loose powder is removed by vacuum.Compared to laser-based powder bed processes like Selective Laser Sintering (SLS), the final parts are said to have high-quality surface finishes, fine feature resolutions, and more consistent mechanical properties. Additionally, since heating occurs layer by layer, with powder filling under the parts, MJF has a lower warpage rate than SLS.To improve surface finish, parts can be sandblasted and then primed or painted. If applications require, printed parts can be dyed or further processed.What materials can be used?Multi Jet Fusion is compatible with a range of thermoplastics from HP, including High Reusability (HR) PA 12 nylon, HR PA 12 GB (glass bead reinforced nylon), and HR PA 11.HP also supports a 3D materials certification program and collaborates with polymer 3D printing material suppliers to develop new materials. Material partners include Arkema, BASF, Dreisler Group, Evonik, Henkel, Lehmann & Voss & Co., Lubrizol, and Sigma Design.Why use Multi Jet Fusion?This process can quickly produce functional prototypes and end-use production parts within a day. If the build unit is swapped out for post-processing after each print is completed, a single MJF printer can virtually run continuously. Used powder can be recycled.MJF’s layer-by-layer fusion is faster than point-by-point 3D printing systems and is said to require the same time for fusion per layer, regardless of complexity. Using MJF, parts can be nested vertically and horizontally, filling the entire build volume with separate individual parts. Multi Jet Fusion does not require mold investments or minimum order quantities; these factors, coupled with its speed, make this process competitive with injection molding in mass production.

△ These sample parts manufactured through Multi Jet Fusion illustrate the design freedom of the process and the potential variety of parts that can constitute a single build. As the printing process does not require support structures, parts can be nested and stacked to fill the entire build volume

The Multi Jet Fusion system consists of replaceable build units that can be moved between MJF 3D printers and separate post-processing stations for rapid cooling and powder removal. This modular system allows printers and post-processing stations to run continuously while build units circulate through, speeding up part production.

△ Periscope housing manufactured on HP’s Multi Jet Fusion 3D printing platform

What post-processing is required?After the build is complete, the build unit (the entire powder bed with encapsulated parts) is removed from the printer and placed in a post-processing unit for rapid cooling. The build unit is then moved to a processing station, where loose powder is removed by vacuum.Compared to laser-based powder bed processes like Selective Laser Sintering (SLS), the final parts are said to have high-quality surface finishes, fine feature resolutions, and more consistent mechanical properties. Additionally, since heating occurs layer by layer, with powder filling under the parts, MJF has a lower warpage rate than SLS.To improve surface finish, parts can be sandblasted and then primed or painted. If applications require, printed parts can be dyed or further processed.What materials can be used?Multi Jet Fusion is compatible with a range of thermoplastics from HP, including High Reusability (HR) PA 12 nylon, HR PA 12 GB (glass bead reinforced nylon), and HR PA 11.HP also supports a 3D materials certification program and collaborates with polymer 3D printing material suppliers to develop new materials. Material partners include Arkema, BASF, Dreisler Group, Evonik, Henkel, Lehmann & Voss & Co., Lubrizol, and Sigma Design.Why use Multi Jet Fusion?This process can quickly produce functional prototypes and end-use production parts within a day. If the build unit is swapped out for post-processing after each print is completed, a single MJF printer can virtually run continuously. Used powder can be recycled.MJF’s layer-by-layer fusion is faster than point-by-point 3D printing systems and is said to require the same time for fusion per layer, regardless of complexity. Using MJF, parts can be nested vertically and horizontally, filling the entire build volume with separate individual parts. Multi Jet Fusion does not require mold investments or minimum order quantities; these factors, coupled with its speed, make this process competitive with injection molding in mass production.

Note from Xiao Ai:

The Swiss Army Knife event has ended! Stay tuned for the new round of Swiss Army Knife giveaways from AMT!

After following this public account, send the keyword “Army Knife” to get event details!

Content source: Internet

This issue edited by: Xiao Ai Advertising and business cooperation: 021-37709287 Phone: 199 4615 0668 WeChat: amtforumSubmissions and interviews: [email protected] (Accepted submissions will be compensated as agreed; for details, follow the public account and send: submission)

Copyright statement: AMT respects copyright and appreciates the hard work and creation of every author; except for articles that cannot be traced, we have noted the source at the end of the text; if there are copyright issues with articles, videos, images, or text, please contact us immediately, and we will confirm copyright based on the proof provided and pay compensation according to national standards or delete the content immediately!