Today, I would like to share a practical case involving a water level control project using PLC, inverter, and touch screen. Let’s take a look at the entire process, which you can save for future reference!

● Project Description

● EM235 Module

● Project Implementation

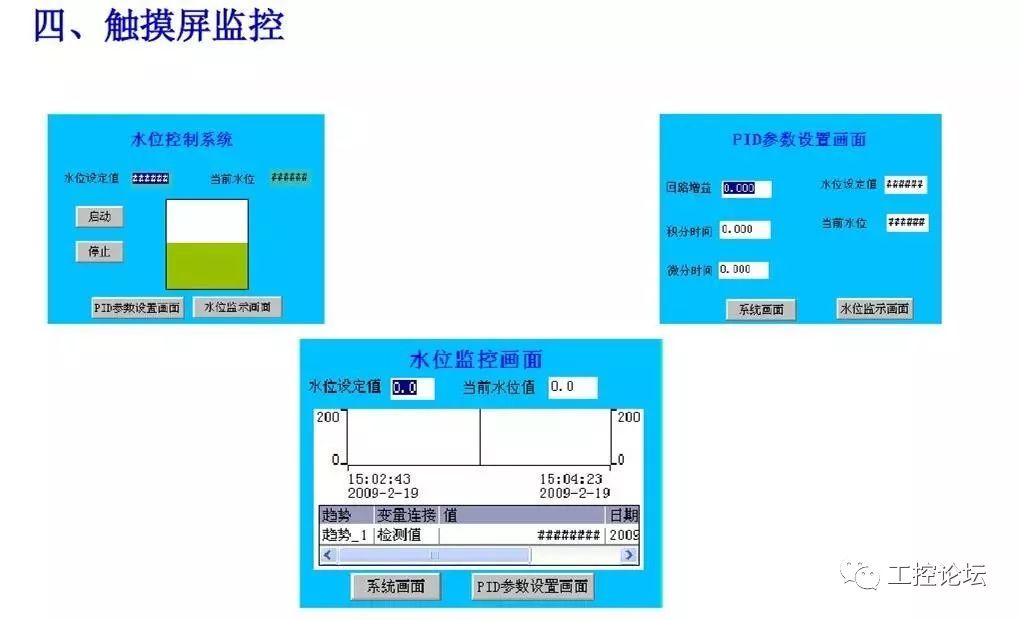

● Touch Screen Monitoring

1. Project Description

1. Project Control Requirements

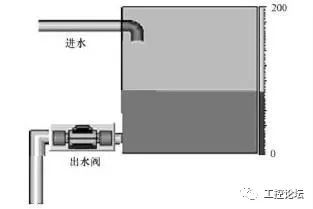

The water tank supplies water to external users, with water consumption being unstable, sometimes high and sometimes low. Water is pumped into the tank, and we need to maintain a constant water level control within a range of 0~200mm (the maximum value can be determined based on the height of the tank). For example, if the set water level is 100mm, regardless of the outflow, the inflow must be adjusted to keep the water level at 100mm. If the outflow is low, the inflow should also be controlled to be low; if the outflow is high, the inflow should be controlled to be high.

2. Control Strategy

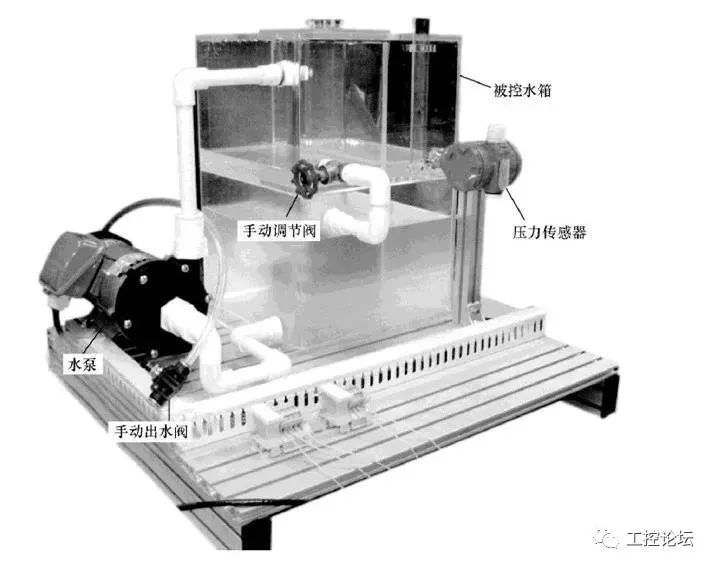

Since the liquid level height is proportional to the water pressure at the bottom of the tank, a pressure sensor can be used to detect the pressure at the bottom of the tank to determine the liquid level height. A PD algorithm is used for automatic adjustment of the water level. The water level signal detected by the pressure sensor (4~20mA) is sent to the PLC, where the PID calculation is performed on the deviation between the set value and the detected value. The calculation result is output to adjust the speed of the water pump motor, thereby regulating the inflow. The speed of the water pump motor can be controlled by the inverter.

3. Component Selection

1) PLC and Module Selection. The PLC can be selected as S7-200 CPU224. To receive the analog signal from the pressure sensor and adjust the water pump motor speed, an EM235 analog input/output module is chosen.

2) Inverter Selection. To adjust the inflow, a Siemens G110 inverter is selected.

3) Touch Screen Selection. A Siemens TP170B touch screen is selected.

4) Water Tank Equipment, as shown in the figure below.

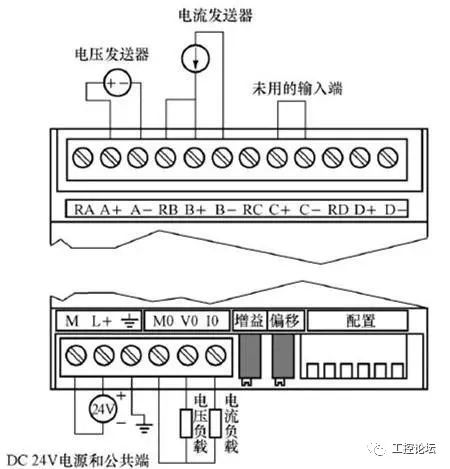

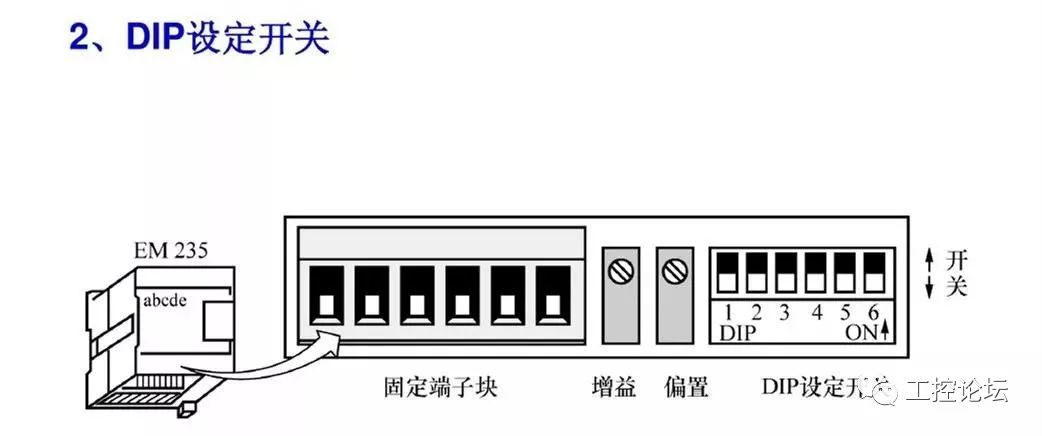

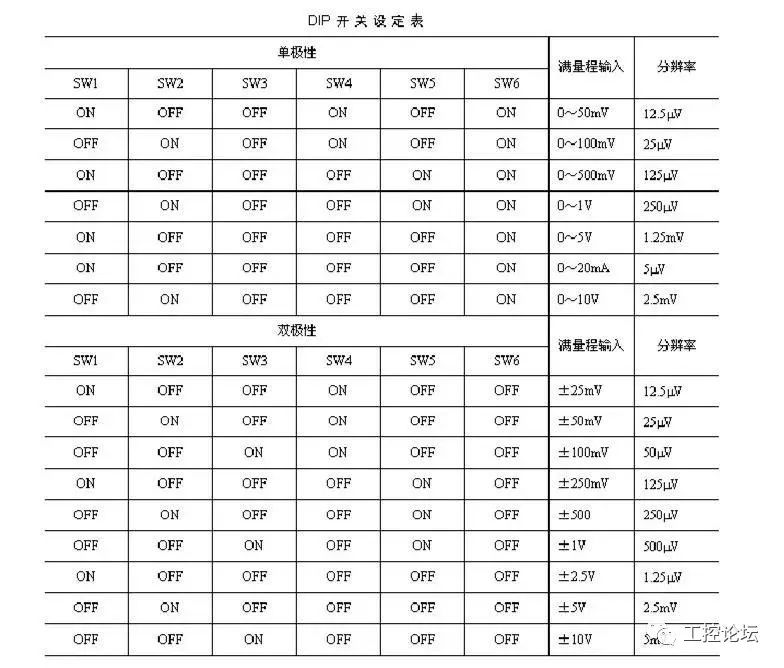

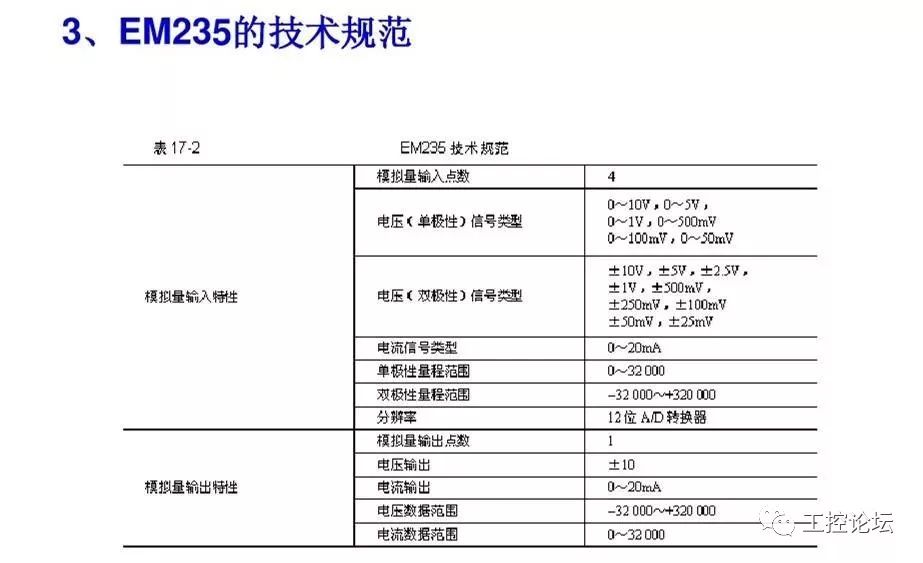

2. EM235 Module

1. EM235 Terminals and Wiring

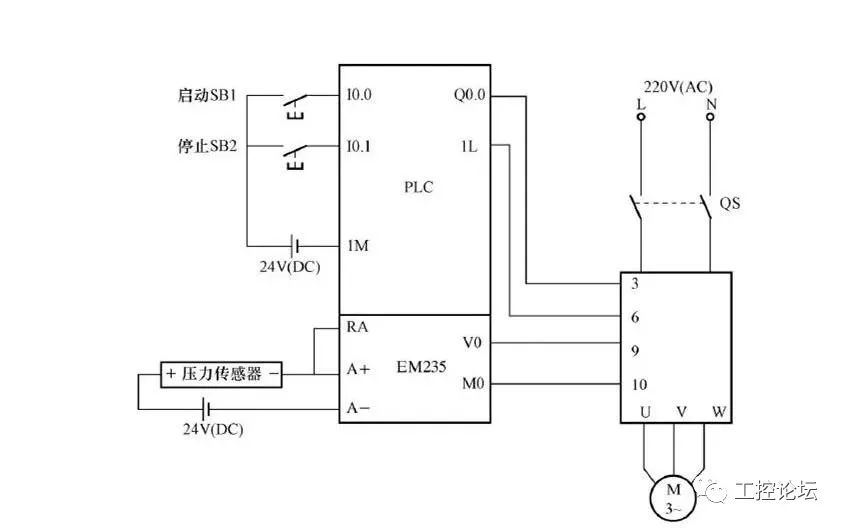

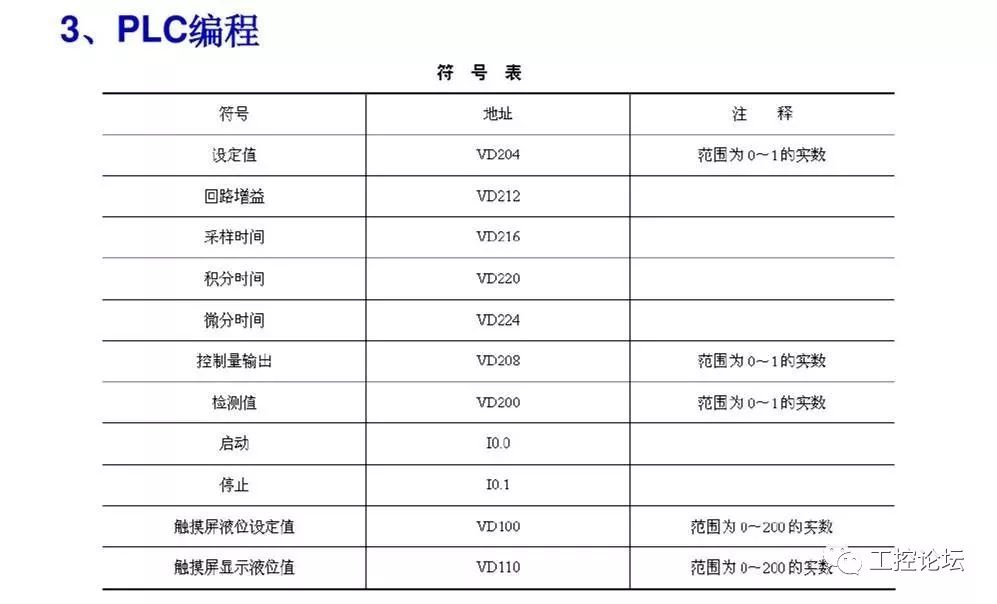

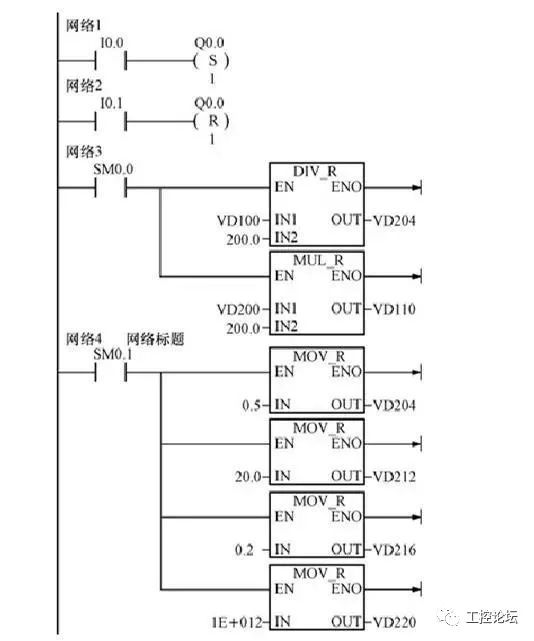

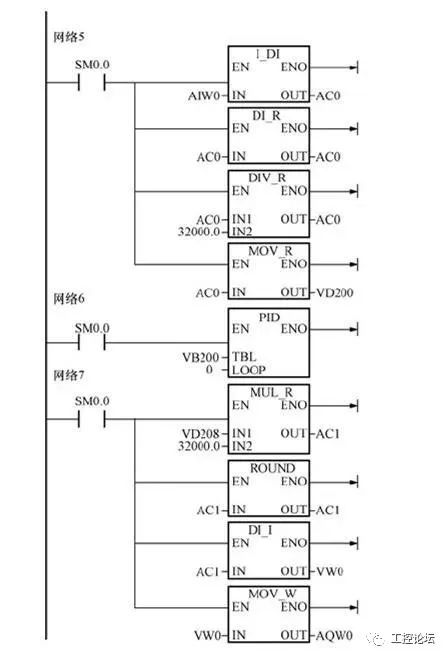

3. Project Implementation

1. PLC IO Allocation and Circuit Diagram

PLC IO Allocation

Start Button, 10.0;

Stop Button, 10.1;

Q0.0, controls the operation of the water pump motor.

Source / Network

Previous Highlights ▼

Original Contributions in Industrial Control

Learn to Easily Understand Control Circuits!

Recommended | Starting with Modbus to Discuss Fieldbus!

Essentials | Starting with Modbus to Discuss Fieldbus!

Thorough Explanation of Gear Knowledge from Shallow to Deep, Recommended for Collection!

76 Typical Violations of Electricity Use on Construction Sites | Pictures Speak the Truth

Classic 24 Q&A of Mitsubishi FX5U Series, Which One Do You Want to Know?

Why Should Motors Use 50HZ AC? You Will Know After Reading!

How Does PLC Control Servo Motors? How to Design a Servo System?

Connection, Examples, and Programming of Siemens PLC with Absolute Encoders

How Much Do You Know About Electrical Knowledge? It Is Said That Only Electrical Engineers Can Guess It

Trial Activity | You Must Have Never Used Such an Advanced Multimeter!

Understand the Superheroes in Motor Control and Protection!

Dynamic Diagram of Mold Structure, Very Comprehensive!

15 Interesting 555 Circuits, Collection!

Various Starting Methods of Motors, Performance, Advantages, and Disadvantages Comparison!

[Industrial Dream Chaser] My Unwavering Dream Pursuit

Organized | Master the Working Principles of Encoders in One Article!

Working Principles and Precautions of PLC Timers (T)

Popular Science on Modbus Protocol

Understand the Working Principles of Solenoid Valves After Reading This!

The Most Comprehensive Summary of Motor Control, Save It!

Understand the Latest Manufacturing Network Technologies, This Meeting in Dongguan Is Just Right!

What Is the Difference Between RS232 and RS485?

Recommended for Collection | Understand Servo Motion Controllers in One Article!

[Group Chat Invitation] Join This Circle of Friends to Experience a Different Industrial Expo

Share a Wave of Basic Mechanical Dynamic Diagrams, If You Don’t Understand, You Shouldn’t Be in Mechanics…

First Time Seeing Such an Explanation of Self-throwing, Surprisingly Understood!

Recommended for Collection | Understand Servo Motion Controllers in One Article!

Principles of Reactive Power Compensation Devices, Full of Essentials!

Recommended | Programming Methods for Logic Control Sequential Control

Master Electrical Main Wiring Knowledge in One Article~

Prize Survey: Six Practical IoT End-to-End Solutions, Which One Do You Want to Know?

Electrical Personnel Interview Case: An Electrical Engineer Actually Doesn’t Know Star-Delta Starting?

Comprehensive Collection of Electrical Fault Diagnosis Mnemonics, 98 Mnemonics for Electrical Engineers, 109 Practical Mnemonics for Electricians, Save It First!

Communication and Programming of Mitsubishi PLC, with Practical Cases

Four Wiring Methods of Current Transformers, Very Simple, Right?

One Article to Understand the Automotive Sensor Industry, So This Is How the Car’s “Facial Features” Look!

Essentials Sharing | Modbus Communication Programming Examples, Exciting Serialization Rhythm!

64 Hydraulic and Pneumatic Animations, Those Who Understand Are Amazing!

How to Achieve Encoder Positioning Function with PLC Control?

New Wave of Drawing Teaching Animations Released!

[New Discoveries in Sinan] This Meter Actually Looks Like This, Popular Female Anchor’s Wonderful Demonstration!

Detailed Explanation of High Voltage Switchgear Power-On and Power-Off Operations, Fault Judgment and Handling

Workshop Maintenance Essentials, Usable Anytime!

Newcomers Come Here! Common Problems of S7-1500T~

Example | Mitsubishi PLC Using RS485 to Control Inverter

Uncommon Engines, All Seen Are Experts!

Recommended for Collection | Common Electrical Formulas and Application Examples!

Super Comprehensive Electrical Engineering Formula Algorithms and Electrical Diagrams, Recommended for Collection!

Understand Motor Wiring Methods in Three Minutes, So Simple!

To some extent, the shortest distance between industrial control personnel is just a small secretary apart. Follow me to gain more resources and information. The little secretary will take you to explore a broader new world of industrial intelligence!

—— Information Secretary

Click “Read the Original” for more.