What is 3D Printing Technology

3D printing, in English, is referred to as Three-Dimensional printing. This technology is a rapid prototyping process that uses techniques such as photopolymerization and paper layering to manufacture components and structures. It operates similarly to the conventional printers we are familiar with; however, traditional printing is a two-dimensional (flat) printing process that uses paper and ink, known as 2D printing. In contrast, a 3D printer contains ‘printing materials’ such as liquids or powders, which are controlled by a computer to layer the ‘printing materials’ one after another, ultimately transforming the blueprint on the computer into tangible objects, machine parts, structural components, and everyday items.Today, this technology is applied in various fields, including the production of clothing, architectural models, automobiles, chocolate, mechanical parts, and aerospace structures.

In simple terms, 3D printing consists of two steps. First, a special adhesive is sprayed in the area to be formed, followed by an even spray of powder. The powder solidifies and bonds where it encounters the adhesive, while areas without adhesive remain loose. This process is repeated until the physical model is ‘printed’ out exactly, indistinguishable from the original. Due to its layer-by-layer processing, which is very similar to conventional inkjet printing, it is referred to as a ‘printer.’

3D printing technology is also known as additive manufacturing or additive processes. The American ASTM International equates additive manufacturing with 3D printing in its materials, stating that ‘additive manufacturing is also known as 3D printing, which uses computer-aided design to prepare layer by layer.’ According to Wikipedia, the precision, repeatability, and range of materials have increased to the point where 3D printing is regarded as an industrial production technology, termed additive manufacturing. Some believe that additive manufacturing is the industrial version of 3D printing.

In contrast to additive manufacturing is subtractive manufacturing, where the conventional manufacturing process of components is based on subtractive techniques. For instance, finished castings and die castings are typically 10% to 20% lighter than the raw materials used, or even more. However, in additive manufacturing, the mass of the workpiece is always increasing, with only a small amount (less than 10%) of cutting processing occurring during part fabrication.

Recently Manufactured Large Structural Components

Using 3D Printing Technology

3D printing technology is a new cutting-edge manufacturing technology currently in the industry. In recent years, the annual average growth rate of sales of 3D printed components has been greater than or equal to 25%. It has gained considerable application in the manufacture of structural components made from aluminum, magnesium, titanium, and stainless steel. The emergence of this process has posed a significant shock and challenge to traditional thinking and design concepts in the industrial manufacturing field, allowing designers’ thoughts and ideas to be released more profoundly and thoroughly. Product design is no longer limited by traditional processing techniques, which is why it is considered one of the typical representatives of the ‘Third Industrial Revolution.’ 3D printing technology can successfully realize designs that traditional subtractive manufacturing techniques find difficult or impossible to achieve, not to mention produce. As a cutting-edge manufacturing technology, the application range of 3D printing has rapidly expanded in just a few years to include dozens of fields and industries, such as aerospace, transportation equipment, shipbuilding, medical devices, sports goods, daily necessities, cultural creativity, high-end clothing, and innovative education.

3D Printed Titanium Alloy Components for Aircraft Landing Gear

It is well known that aircraft landing gear is a very important structural component, which experiences significant impact forces during landing. Some of its parts were previously forged from high-strength aluminum alloys (such as 2024 and 7075 alloys) or titanium alloys. In early 2021, Safran Group’s Safran Landing Systems used Direct Metal Laser Sintering (SLM) technology to print the landing gear housing for a business jet, with dimensions of 455mm × 295mm × 805mm. This is a large component for 3D printing, made from Ti-6Al-4V powder alloy. Compared to aluminum alloy components forged using traditional processes, its weight decreased by 15%, while also possessing higher mechanical properties to withstand greater stress. The project’s R&D platform leader stated: ‘This is a component that bears significant pressure and must be able to rotate on its pivot so that the landing gear can retract under the aircraft, and it must absorb the mechanical stresses from the aircraft wheels. This is the first time in the world that a critical part of this nature and size has been produced using additive manufacturing.’

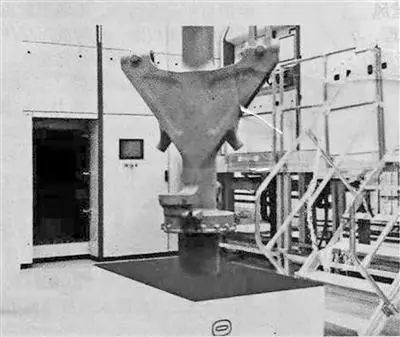

3D Printed Titanium Alloy Housing for Landing Gear

The titanium alloy housing for the landing gear was printed on the SLM 800 additive manufacturing machine, renowned for its four-laser technology and reliability. The engineers did not use a 6-axis machine to produce the housing component in three separate parts, but instead manufactured it in one piece, eliminating costly and time-consuming assembly. By adapting the new design scheme for additive manufacturing, the housing’s weight was reduced by 15%, and the printing time was significantly shortened, achieving a win-win situation, allowing Safran Group to reach its long-sought two goals.

Traditionally, this housing is forged from high-strength, high-toughness aluminum alloy, but Safran Landing Systems considered that the strength and corrosion resistance of the Ti-6Al-4V alloy surpass those of aluminum alloys, so they opted for the proven titanium alloy. The company stated that 70% of the surface of the printed titanium alloy housing did not undergo any machining, with only a slight machining performed on a few functional surfaces to extend its service life. Currently, the company plans to conduct certification tests on the printed housing in 2022, as aircraft components must be certified by relevant authorities, which is a crucial step.

Integrated Printing of 10m-Class High-Strength Aluminum Alloy Heavy-Lift Rocket Connecting Ring Prototype

In January 2021, the National Additive Manufacturing Innovation Center and Academician Lu Bingheng’s team from Xi’an Jiaotong University utilized additive manufacturing technology to produce the world’s first 10m-class high-strength aluminum alloy heavy-lift rocket connecting ring prototype. They achieved significant technological breakthroughs in stability, precision control, deformation, and stress control through the integrated additive manufacturing process, reaching unprecedented new heights and realms globally.

The 10m-class super-large aluminum alloy ring component is a critical structural part connecting the storage tank sections, front and rear bottoms, and the rocket box sections of the heavy-lift rocket. It is typically made from 2219 aluminum alloy, weighing about 1 ton. Academician Lu’s team innovatively used a multi-wire collaborative process equipment, greatly simplifying the process, significantly reducing production costs, and notably shortening the printing cycle, completing it in just one month.

Academician Lu’s team has successfully completed the production of super-large ring components using integrated additive manufacturing technology, marking an international first. This achievement will help additive manufacturing elevate China’s aerospace endeavors to greater heights, providing robust technical support for the rapid manufacturing of significant structural components in the country’s aerospace industry.

10m-Class Aluminum Alloy Ring Component for Rockets Produced by Southwest Aluminum Group, Identical to the One Printed Using Integrated Additive Manufacturing Method by Academician Lu’s Team.

10m-Class Aluminum Alloy Ring Component for Rockets Produced by Southwest Aluminum Group, Identical to the One Printed Using Integrated Additive Manufacturing Method by Academician Lu’s Team.

Titanium Micro Media ∣Using Titanium as a Medium.

Focusing on the top-level wisdom of the titanium industry; delivering the latest news in the titanium industry;

Salons facilitate discussions in the titanium community; academic support for the flourishing of titanium;

The non-ferrous report conveys titanium information, and the titanium industry version provides a titanium garden.