Skip to content

Rhinoceros How to Print Models with 3D Printing?

03 How to Operate Rhinoceros

Industries traditionally involved in 3D design, such as animation and architecture, often neglect the physical world while modeling, focusing solely on the appearance of the 3D model. Most scenes and objects consist only of visible meshes, and objects are made up of faces (which have no thickness) and lines, not necessarily connected. However, if you want the 3D model you design to be used on a 3D printer and printed perfectly as expected, you must understand the following points:

1) The 3D model must be watertight.

In simple terms, it means “closed” or “not leaking.” Here, watertight means the 3D model must be a complete boundary entity; if the model has holes, the printer cannot recognize the boundaries and cannot print. You can also use some software to check if your model has such issues, for example, AccuTrans, which can automatically mark non-watertight areas for you (Rhinoceros’ edge detection can also be used).

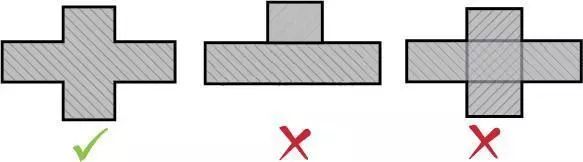

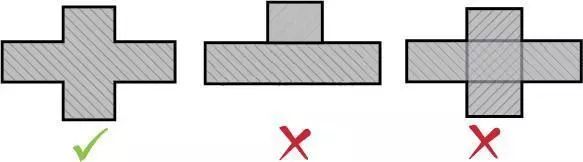

2) The 3D model must be manifold.

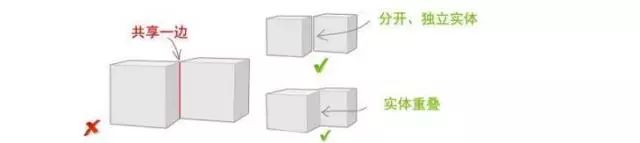

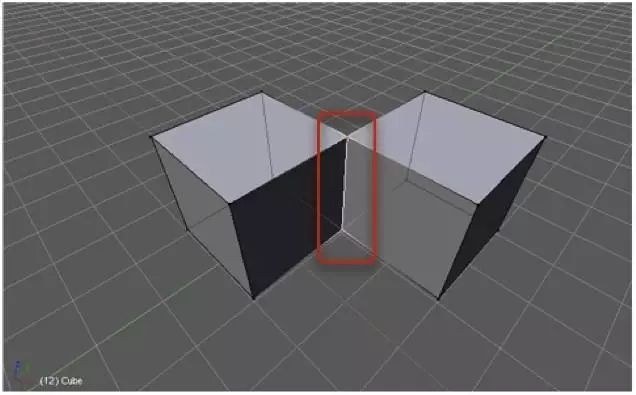

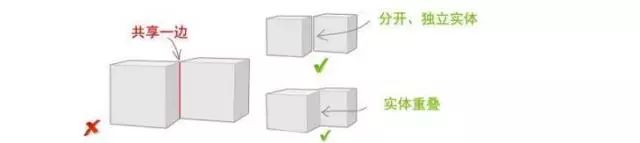

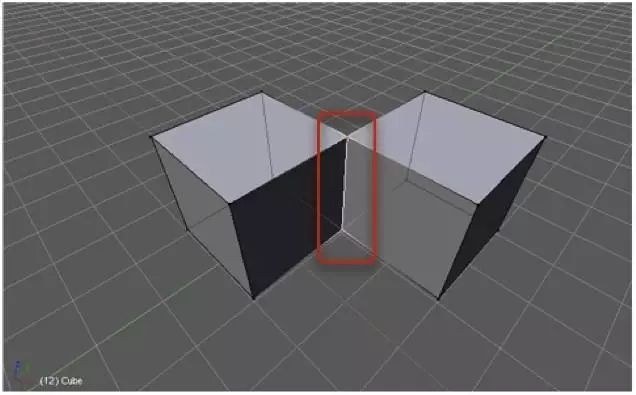

Manifold is a mathematical concept; you can imagine a flowing surface where there are no lines or faces, only surfaces and volumes. Simply put, if a model has multiple faces sharing an edge, it is non-manifold. For example, in the case below:

Two cubes share an edge; in other words, four faces share this edge.

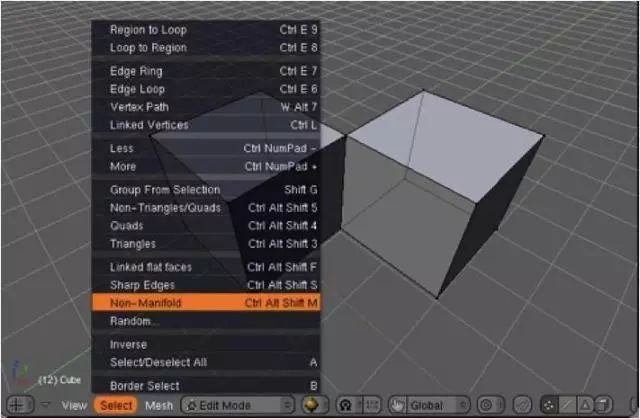

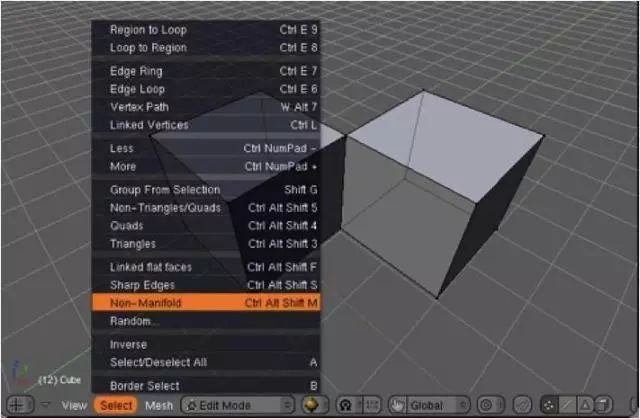

The free software Blender has a function to determine whether the 3D model has non-manifold areas, which we can demonstrate in Blender, as shown:

Select Non-Manifold to display.

Of course, many other 3D software also have this function.

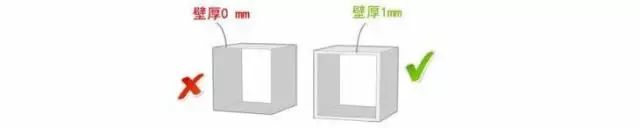

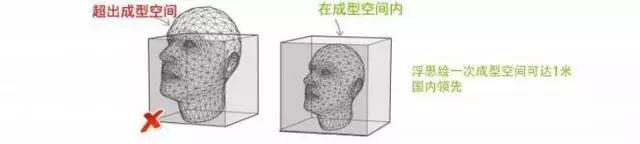

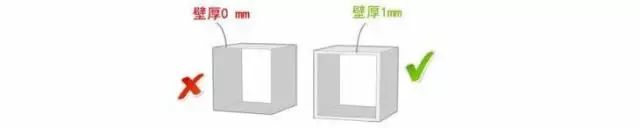

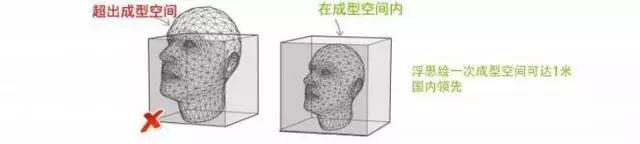

3) The maximum size and minimum wall thickness of the 3D model.

The maximum size and wall thickness of the 3D model depend on the 3D printing technology and materials you plan to use. Here, you should note the one-time forming size; generally, do not exceed one meter, as different materials have different maximum forming sizes. You need to consult the 3D printing service provider for specific situations. Generally speaking, larger models should not have a minimum wall thickness lower than1mm, otherwise the model will be fragile and prone to deformation.

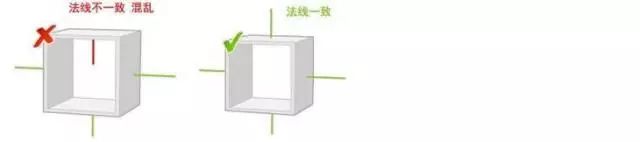

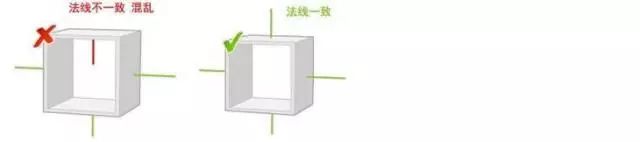

4) All face normals of the 3D model must be consistent.

All normals on the faces of the 3D model need to point in a correct direction. If your model contains conflicting normals, the 3D printer cannot determine whether it is the inside or outside of the model.

5) Pay attention to merging duplicate and intersecting parts.

The 3D files to be printed should also follow these rules or suggestions:

(1) If only the appearance is needed, try to make it a hollow model (with a thin wall but ensuring the shape is not easily damaged) to effectively save costs;

(2) Pay attention to the one-time forming size; 3D printing PLA materials can print items up to 1000 millimeters. Different materials have different maximum forming sizes.

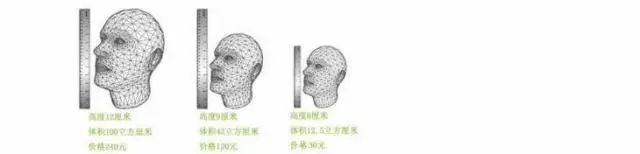

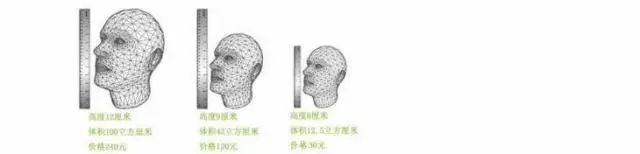

(3) The relationship between price and size is almost cubic, so the larger the size, the higher the price, and the increase is very fast!!

(4) If you want to successfully print movable items or jointed items at once, there needs to be a gap of 0.5mm at the joints or connections.

(5) For structures with cantilever, make the cantilever structure thicker to prevent deformation during printing.

(6) For objects with large curvature, such as cylinders, if printed with transparent materials, the transparency will not be as good as flat objects.

(7) The minimum detail on the surface should not be less than 0.2mm

(8) There should be no thin lines less than 1mm

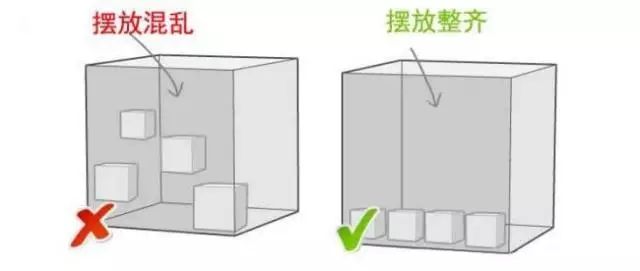

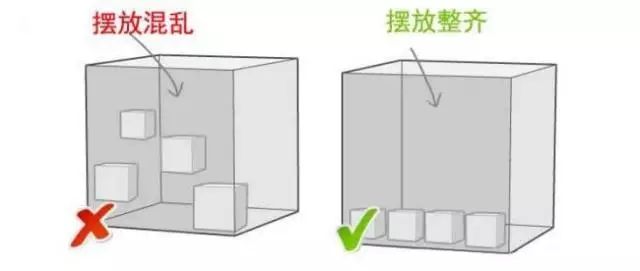

(9) Printed objects need to be arranged neatly.

Designing models for 3D printing differs from traditional 3D design, but it does not mean 3D designers need to relearn everything; it mainly involves understanding some new concepts. If you remember these concepts and constraints while designing, 3D printing design is not difficult.

How to Operate Rhinoceros

The model format generally recognized by 3D printing is STL (the most commonly used).

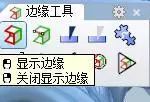

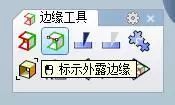

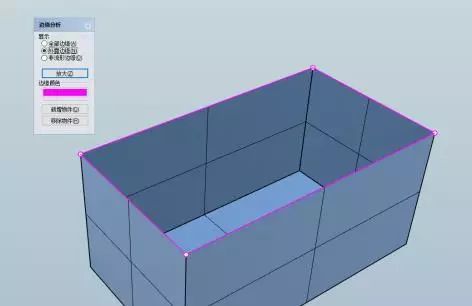

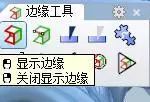

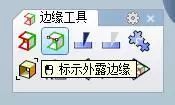

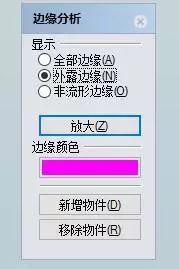

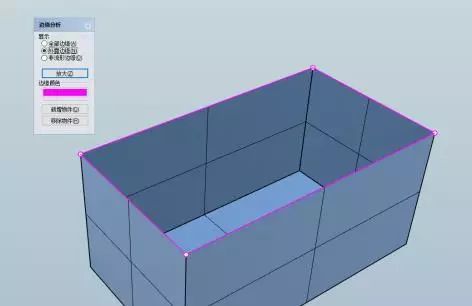

First, perform edge detection on the model; these two tools can be used to show exposed edges.

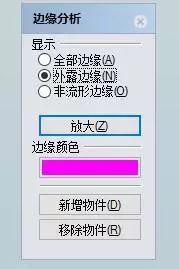

Both non-manifold edges and exposed edges can be detected at once, allowing for immediate modifications if issues arise.

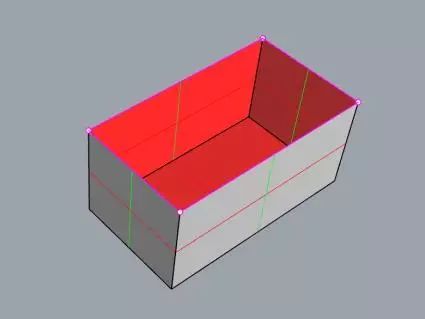

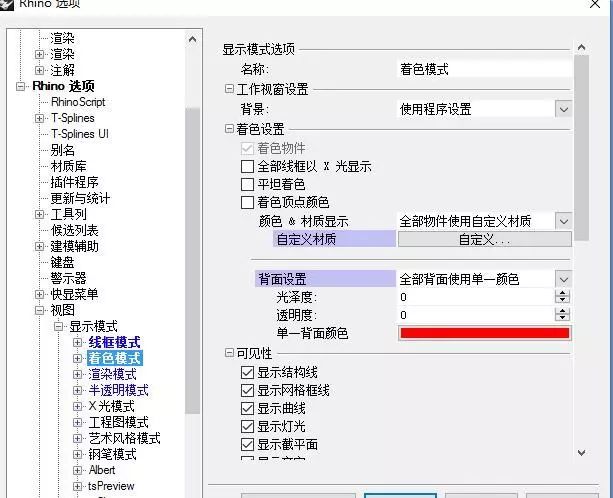

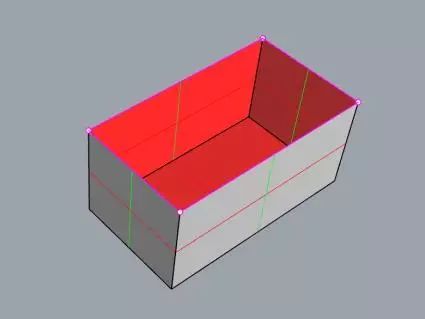

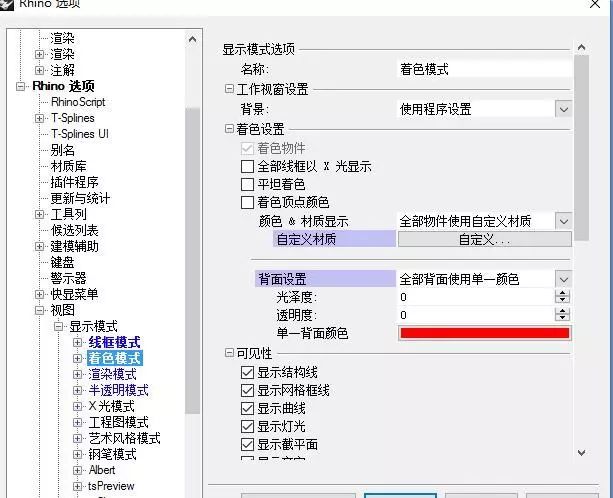

The model has a front and back; if there are contradictions in the front and back of a model, it cannot be printed. Here, it is suggested to set the back color to red in shaded mode as a warning.

(This can be set in the settings)

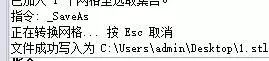

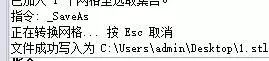

When exporting formats like 3DS or STL from Rhinoceros, you must first convert NURBS to mesh before exporting.

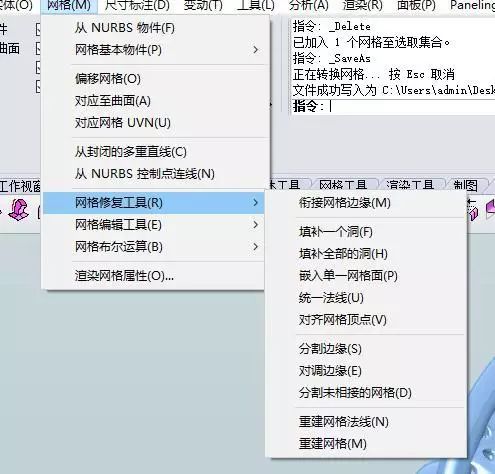

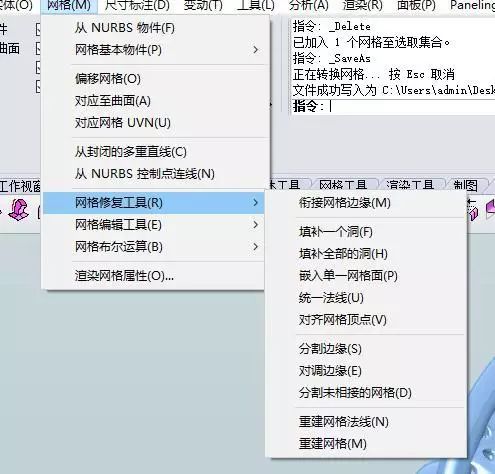

So you can manually convert to mesh in Rhinoceros for 3D printing. The models received often have some errors. Rhinoceros has a powerful function called Mesh Repair Tool, which can forcibly weld unconnected mesh faces, fill holes, unify normals (front and back), and even rebuild mesh, which is very convenient.

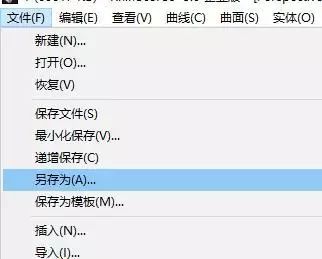

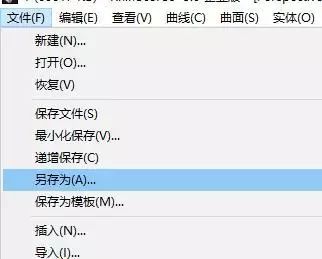

Finally, export to STL format from here.

If you need 3D printing services, just find someone on Taobao, send them the STL model, and they will start quoting based on the model. Here, it is emphasized that 3D models cannot be estimated by humans; it is very difficult to rely on experience because the shape determines how much material is used, and there are many factors involved. Therefore, it is impossible for 3D printing sellers to estimate without seeing the model, and relying on experience is also very difficult.

As architecture students, we usually use PLA and photosensitive resin as materials for models. The price of PLA on Taobao is 60-140 yuan per kg, but printing sellers will sell it for 0.8 yuan/g because 3D printing requires a lot of service work. This price has already dropped significantly compared to two years ago, and I believe this price is generally acceptable for students doing assignments. The price of resin has also dropped significantly this year; I remember it was 2.8 yuan/g. The difference between the two is that resin has no surface texture, is very smooth, but is fragile and will yellow over time. PLA feels sturdier than resin and can be stored for a long time, but the surface texture and reflectivity can affect the effect. I usually spray a layer of paint over PLA prints.

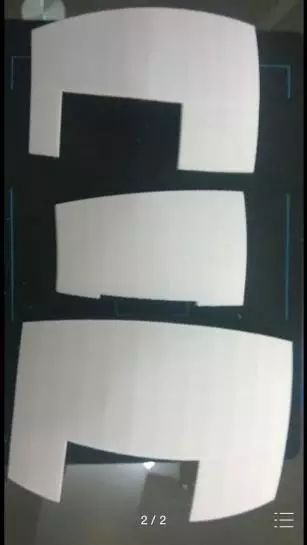

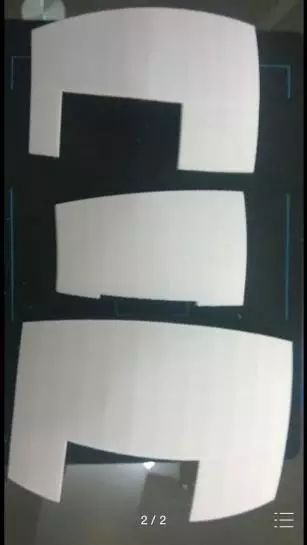

This is my model assignment from my freshman year; the three-arc wall is printed with PLA, and mixed with PVC material, it is actually indistinguishable. Upon closer inspection, you can see the texture, and the hardness is much higher than PVC, so the effect is quite good.

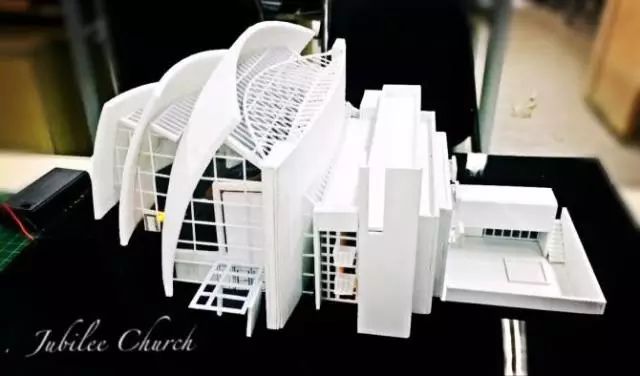

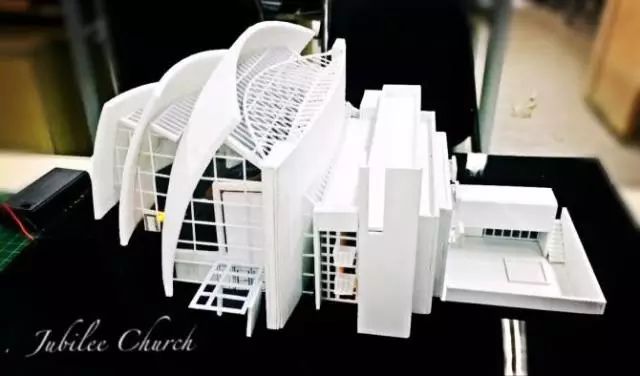

The white part is printed with photosensitive resin and then sprayed with matte paint; the surface is very smooth and feels good. The downside is that it will definitely break if dropped and will yellow over time.

Written by: Li Zhi, Cao Ning

If you need to reprint, please contact the author Li Zhi and indicate the source.