Recently, Tsinghua University’s Department of Mechanical Engineering, Modern Mechanisms and Robotic Equipment Laboratory has developed a pipeline inspection robot capable of efficient movement in sub-centimeter pipelines.

This unusual design inspiration comes from earthworms.

Despite its small size, the robot has significant applications! This article will detail its working principles, key technologies involved, and future application directions.

▍Miniature Pipeline Robot Capable of Navigating Curved Pipelines

In complex systems such as aircraft engines and refineries, there are numerous pipelines used for transporting water, gas, and oil. Typically, these pipelines have various diameters, changing curvatures, and cover long distances. To ensure they are in good working condition, regular inspections from both the outside and inside are required.

However, the various pipeline inspection robots developed so far include wheeled, legged, and tracked types, most of which are driven by electromagnetic motors and are suitable for inspecting large-diameter pipelines. When it comes to micro-pipelines with diameters less than one centimeter, it is challenging to scale down the size of the robots.

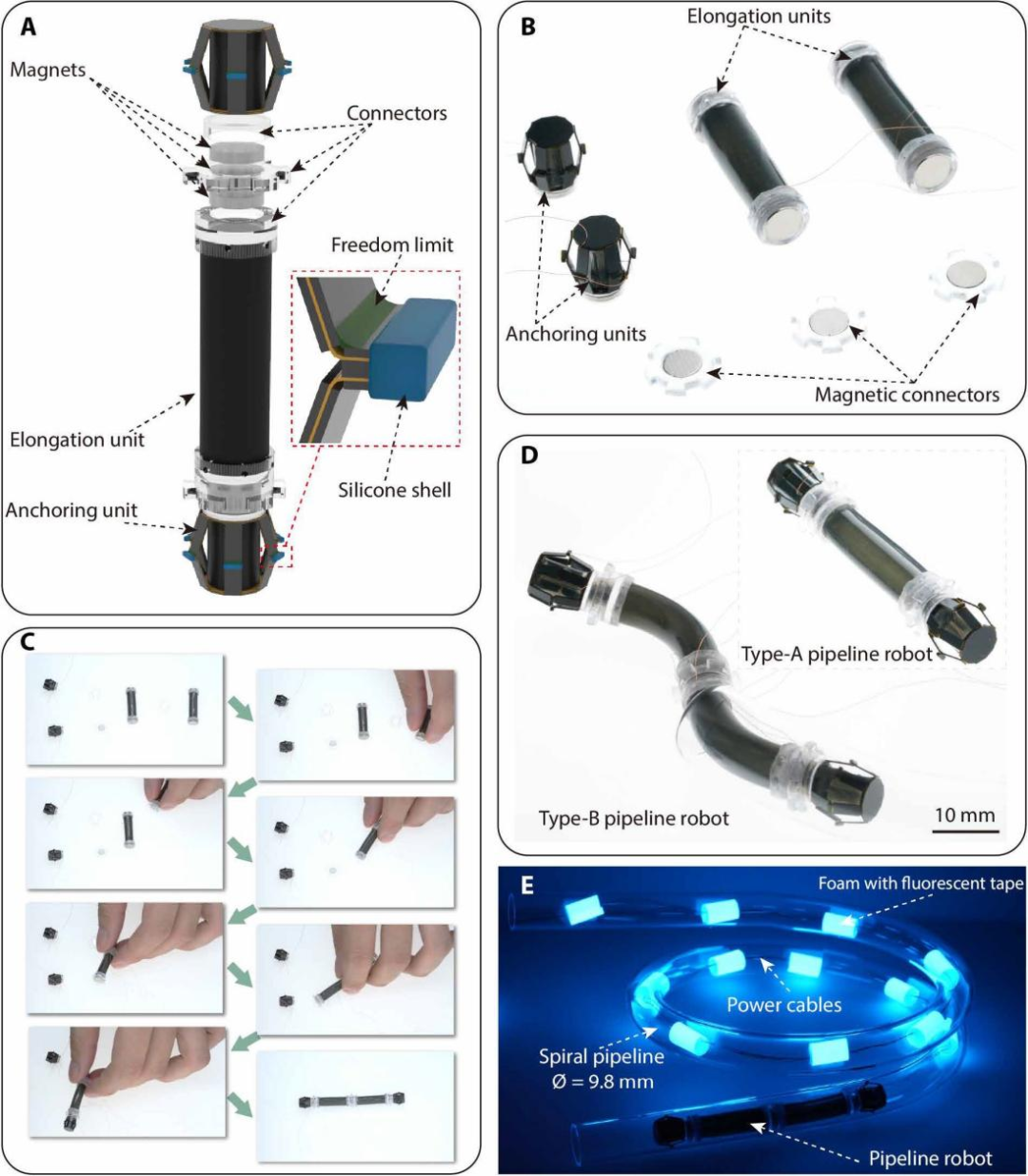

Based on this challenge, the team proposed a smart material-driven miniature pipeline inspection robot (weighing 2.2 grams, measuring 47 millimeters in length, and with a diameter of < 10 millimeters), which can adapt to complex pipelines with sub-centimeter diameters and varying curvatures.

Design and Assembly of the Pipeline Robot

So, how can technology be used to create this type of robot?

The key lies in—artificial muscles (also known as “soft actuators” or “dielectric elastomer actuators”) that are powerful enough yet small enough to drive the robot to move quickly within the pipeline.

Minimizing size to fit sub-centimeter pipelines while still achieving effective movement, and designing the drive mechanism to accommodate various pipelines, are the biggest challenges.

This robot uses high power density, long-life dielectric elastomer actuators as artificial muscles, and employs efficient anchoring units based on smart composite microstructures as the drive mechanism, utilizing adjustable magnetic units for rapid assembly of the robot to adapt to the complex geometries of different pipelines.

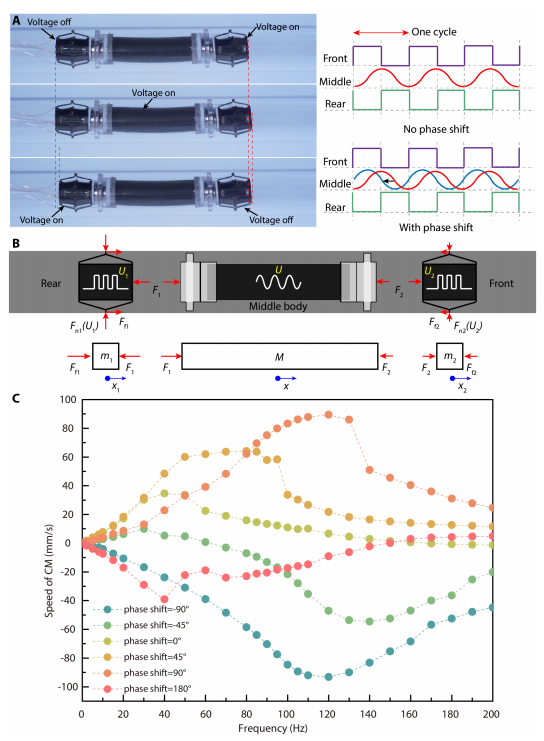

At the same time, the researchers analyzed the robot’s dynamic characteristics by considering the unique properties of soft materials (such as viscoelasticity and dynamic resonance) and accordingly adjusting the frequency and phase of the driving voltage to optimize the robot’s movement speed.

Motion analysis of the A-type pipeline robot. (A) Basic motion and driving signals of the robot within one cycle. (B) Free body diagram of the robot’s independent components. (C) Frequency and phase diagram of the robot’s CM simulated speed.

▍External Cable Provides Power for Rapid Movement

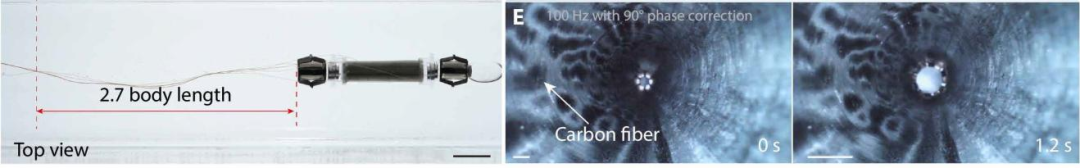

Additionally, this pipeline robot, based on high-frequency peristaltic motion principles, is powered by external cables, achieving rapid horizontal and vertical movement in sub-centimeter-sized pipelines (speed: 1.19 body lengths/second).

Horizontal Movement

Vertical Movement

At the same time, it can also move at high speed in pipelines of different geometries (converging pipes, L-shaped pipes, S-shaped pipes, spiral pipes, etc.), different filling media (air, oil, etc.), and different materials (glass, metal, carbon fiber, etc.).

L-shaped Pipe

Spiral Pipe

The robot navigates through pipelines filled with liquid oil and those made of carbon fiber.

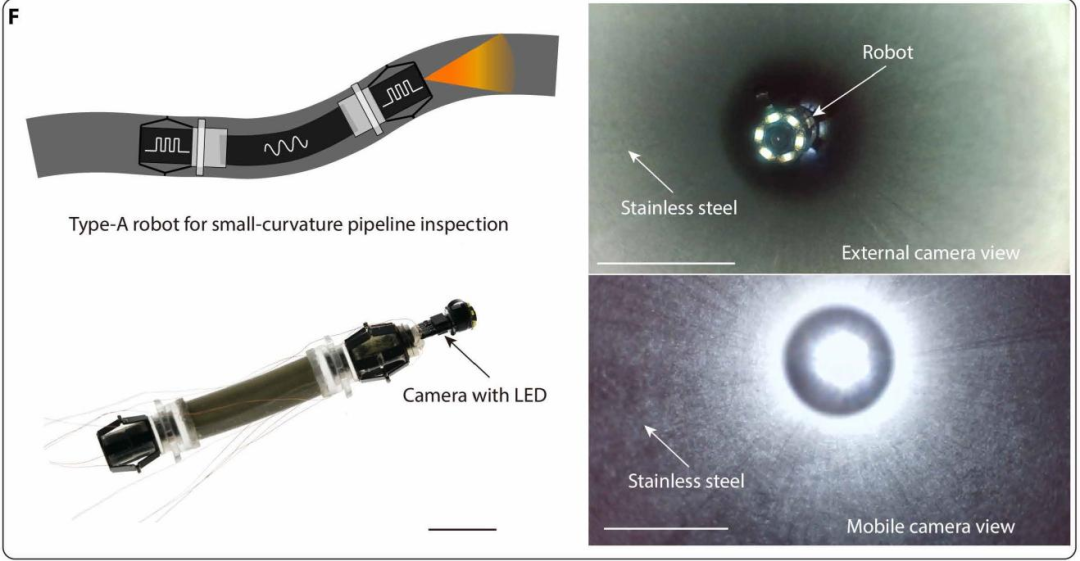

To verify its pipeline inspection capabilities, the robot is equipped with a miniature camera mounted at the front, controlled externally, and successfully completed a series of pipeline inspection tasks at different speeds.

The robot’s image, with a camera mounted at the front, inspecting the environment inside a stainless steel pipe at a driving frequency of 1 Hz. Scale bar, 10 mm.

▍Expected to Play a Role in Aircraft Engine Pipeline Maintenance

The aforementioned research results were published in Science Robotics under the title “A pipeline inspection robot for navigating tubular environments in the sub-centimeter scale.”

The first author of the paper is Dr. Tang Chao, a postdoctoral researcher in the Department of Mechanical Engineering at Tsinghua University, who graduated with a PhD from the School of Mechanical Engineering at Xi’an Jiaotong University, under the supervision of Professor Chen Hualing. In June 2020, he joined Tsinghua University’s Department of Mechanical Engineering, Modern Mechanisms and Robotic Equipment Laboratory for postdoctoral research, with co-supervisor Associate Professor Zhao Huichan, focusing on smart materials and structures, and soft robotics.

Dr. Tang Chao, Postdoctoral Researcher, Department of Mechanical Engineering, Tsinghua University

The corresponding author of the paper is Associate Professor Zhao Huichan from the Department of Mechanical Engineering, with other authors including Professor Liu Xinjun from the Department of Mechanical Engineering and PhD students Du Boyuan (2021), Jiang Songwen (2018), Shao Qi (2019), and Dong Xuguang (2019). The team has been focusing on research related to robotics for many years.

In this research, the development team demonstrated the feasibility of rapidly assembling and constructing tethered, sub-centimeter diameter pipeline inspection robots using smart materials and structures. Compared to other types of pipeline robots, this pipeline robot has higher environmental adaptability.

Current methods for inspecting aircraft engines are very time-consuming and require highly skilled engineers. The research team hopes to deploy such robots into the pipelines of aircraft engines, allowing the robots to navigate through the pipelines while sending back all images along the way, saving time and effort for people.

This research is expected to play a role in fields such as aircraft engine pipeline maintenance.

This work was supported by the National Natural Science Foundation of China Youth Fund, general projects, and the major research program for collaborative robots.

Paper Link:

https://www.science.org/doi/10.1126/scirobotics.abm8597

Typesetting | Mai Zi

—————–END——————-

More Exciting Content

*In 14 years, KUKA AMR has made significant progress and is now emerging.

*With pressure to reduce costs, increase efficiency, and speed up, can industrial software help the construction industry out of its predicament?

*In the red sea, this company has carved out a niche by deeply exploring demand.

*With a focus on the central region, Estun’s performance continues to grow steadily, and its major client strategy is ongoing, with orders in the first half of the year expected to exceed expectations.

*With a single batch purchase exceeding 1,000 units, how does the development of agricultural robots add up to an “economic account”?

*Cross-industry ride-sharing! Science Robotics reports on Beihang University’s “cross-medium adsorption bionic robot”.

*What “secret weapons” do these super impressive bionic robots use?

*Solving the cleaning challenges in all scenarios, with timeliness and intelligence maximized, this company’s new product launch has already signed contracts worth over 100 million.

*In the field of robotics, this trillion-level market remains to be developed…

*Production of Xiaomi’s sweeping robot has been halted.

*The Max Planck Institute for Intelligent Systems (MPI-IS) is recruiting two fully funded PhD students in Dr. Hu’s research group.

*Jieka’s hard-core strength achieves a “small giant” leap.

*”Industrial Scene Innovator” xMate CR makes its debut, with a significant discount ongoing.

*Geek Innovation Competition | The Micro-Invasive® Robot Ship is about to set sail.

*VisionBit’s “AI + 3D Vision” core product | Intelligent feeding and sorting production line.

*The introduction of collaborative robots brings new growth highlights to the home appliance industry.

*Elite has been recognized as the 2022 Suzhou Intelligent Perception Collaborative Robot Engineering Technology Research Center!

*Casual Talk: SCARA in Transition.

*Need help getting dressed? MIT develops a new algorithm for robots to assist humans in putting on “sleeved” clothing!

*The team from Beijing Institute of Technology magnetizes micro-robots to simulate “parkour” in blood vessels and can manipulate micro-objects.

Join the Community

Welcome to join the 【Robot Lecture Hall】 reader discussion group, to discuss topics related to robotics and share cutting-edge technology and industry dynamics.

Discussion groups on educational robots, medical robots, legged robots, industrial robots, service robots, special robots, drones, soft robots, etc. are recruiting. Follow the Robot Lecture Hall public account and send ” Group Chat ” to get the joining method!

Recruiting Authors

The Robot Lecture Hall is recruiting 【part-time content creators】. If you are interested in writing articles related to robotics 【technology】 or 【industry】, please send your resume and original works to the email: [email protected]

We have no requirements for profession or location, and welcome friends to join!

Feeling tired? Click “Looking” to support us!