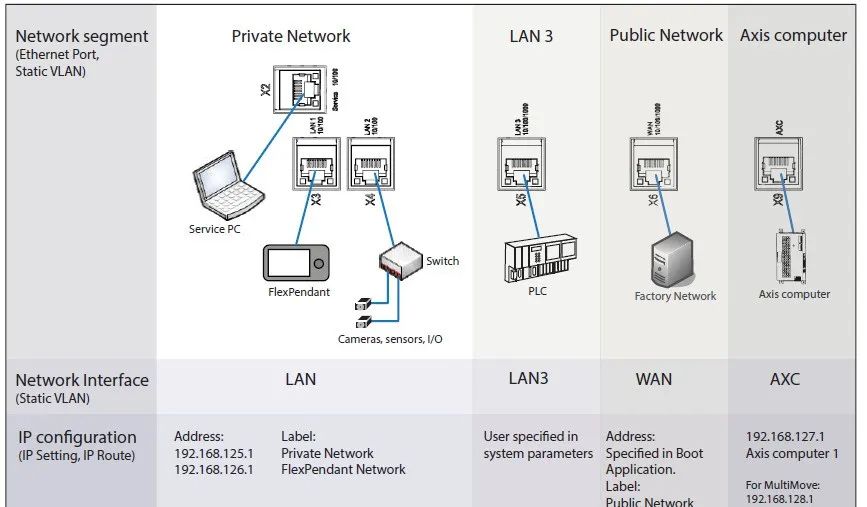

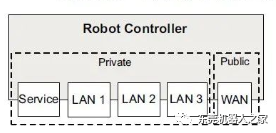

1. The ABB robot controller has several network ports, defined as follows:

2. The several network ports within the Private Network essentially function as different ports of a switch.

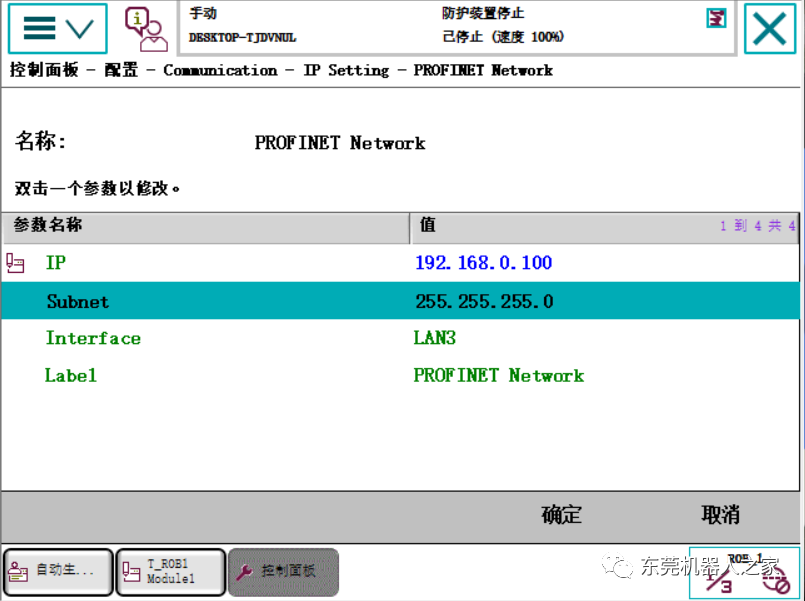

3. By default, the Lan3 port is isolated, as shown in the image below. At this point, you can configure an IP for the LAN3 port in the IP settings.

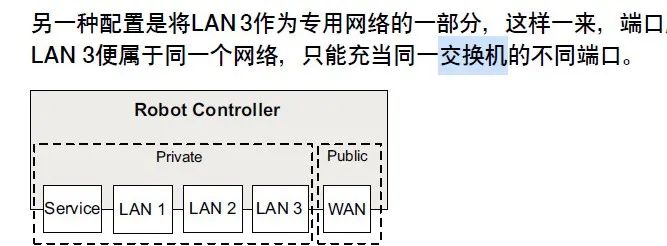

4. You can also configure the Lan3 port as part of the Private network, as shown in the image below.

Open the control panel – Configuration – Theme communication – static VLAN – X5, set the Interface to LAN (the default is LAN3).

At this point, both LAN2 and LAN3 can serve as different ports of a switch.

Since Service, LAN1, LAN2, and LAN3 are all part of the Private network, they function as different ports of a switch. You can also connect the PC’s network cable to LAN3 or LAN2 and connect the robot through Robotstudio (the connected robot IP is 192.168.125.1). If you configure PROFINET or Ethernet/IP associated with the PRIVATE label, you can use LAN2 to LAN3 to make the robot a node on the ring network.

Note!!!!!!!The PRIVATE networks of two robots cannot interconnect!!!!

Past Highlights:

-

Tips on FANUC robot backend logic applications

-

How to perform image backup and restoration on FANUC robots

-

Steps for FANUC spider mobile robot to calibrate the origin

-

How to add GSD files for Siemens 1200 PLC and ABB robot Profinet communication

-

Introduction to KUKA robot teach pendant SmartPad user groups

-

Common commands for KUKA robots

-

KUKA robot playing Tetris

-

Kuka robot soft servo function

-

Creating and uploading online connection programs in KUKA Workvisual

-

KUKA robot simple origin return program

-

KR C4 Compact electrical maintenance manual troubleshooting

-

Explanation of KUKA program instructions (Part 3)

-

Maintenance of KUKA robots

-

Profinet communication setup for Siemens 1200 PLC and ABB robot

-

Quick creation of workpiece coordinates in ABB Robotstudio simulation software

-

Quick creation of tool coordinates in ABB Robotstudio simulation software

-

Detailed explanation and application of ABB robot TEST instruction

-

ABB robot WorldZone safety area function output HOME work origin signal

-

ABB robot sending joint position data through timed interrupts

-

Methods for ABB robot mold repair and electrode cap replacement

-

ABB robot WAN port using socket and Profinet simultaneously

-

Simple CPU communication setup between multiple Mitsubishi FX5U PLCs

-

ABB robot packaging a point plus a length into a function instruction

-

ABB robot packaging a point plus a length into a function instruction

-

Profinet communication setup for Siemens 1200 PLC and ABB robot

-

How to add GSD files for Siemens 1200 PLC and ABB robot Profinet communication

-

Common soft component meanings for Siemens Smart200 PLC

-

Quick creation of tool coordinates in ABB Robotstudio simulation software

-

ABB robot WorldZone safety area function output HOME work origin signal

-

Methods for ABB robot mold repair and electrode cap replacement

▼东莞机器人之家,关注有惊喜

▼

小编微信☜

公众号二维码☞

单击对应二维码,长按添加小编为好友▲