Follow the “Automation Control System Communication” public account to learn about the principles of automation control systems and master knowledge of automation control systems. Click the blue “Automation Control System Communication” above to follow us.

In DCS systems, the Modbus communication protocol is often heard of, while Siemens’ PLC often encounters the PROFIBUS communication protocol. What exactly are these concepts, and can the two protocols communicate with each other? The following article summarizes these points for reference.

Modbus protocol was originally developed by Modicon company, which became part of Schneider Automation at the end of 1979. Now, Modbus has become the most popular protocol in the industrial field globally. This protocol supports traditional RS-232, RS-422, RS-485, and Ethernet devices. Many industrial devices, including PLC, DCS, smart instruments, etc., use the Modbus protocol as their communication standard. Different interfaces have different rates.

PROFIBUS protocol and its network consist of three main parts:

1. Profibus DP (Distributed I/Os): This communication method uses polling between master and slave stations, mainly applied in unit-level and field-level communication in manufacturing automation systems.

PROFIBUS PA (Process Automation): Power and communication data are transmitted in parallel through the bus, mainly used for unit-level and field-level communication in process automation systems.

PROFIBUS FMS (Fieldbus Message Specification): This defines the communication model between master stations, mainly for system-level and workshop-level process data exchange in automation systems.

2. Profibus network consists of master stations, slave stations, network components, etc.: The master station is also known as the active node, including SIMATIC PLC, SIMATIC WinAC controllers, communication processors that support master station functions, IE/PB link modules, and master modules of ET200S/ET200X. Typical slaves include sensors, actuators, and frequency converters. Slaves do not have authorization for bus access.

The transmission speed of Profibus is 9.6/19.2/93.75/187.5/500/1500 Kbit/s and 3/6/12 Mbit/s. The maximum number of nodes is 127 (addresses 0-126).

Profibus transmission speed is 9.6/19.2/93.75/187.5/500/1500 Kbit/s and 3/6/12 Mbit/s. However, the transmission distance varies with different communication speeds; the higher the speed, the shorter the transmission distance. The theoretical transmission distance for Modbus communication protocols RS-422 and RS-485 is 1200 meters, and for RS-232 is 12 meters.

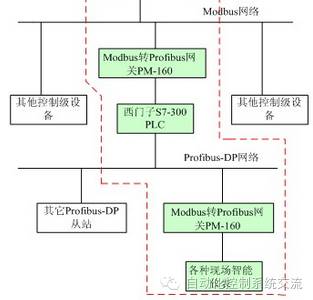

Using the Modbus-RTU protocol, you can choose from several serial ports: RS485, RS232. If connecting multiple devices via Siemens PLC with the profibus-dp end, you can use an industrial communication gateway. If connecting one device, an industrial communication adapter will suffice.

That’s all for today. We will continue to update our knowledge of systems, and we welcome everyone to follow the WeChat public account “Automation Control System Communication”.

Scan the image below to follow the “Automation Control System Communication” public account (long press to identify).