The “brain” of the industrial robot, the controller, is designed and implemented in this article!

Currently, there are mainly two ways to design and implement robot controllers in the market:

The first method is to follow a completely self-research and development route, where everything from hardware design to software module programming is fully accomplished by the company’s own team. However, pursuing this completely self-research route poses too much risk for the vast majority of domestic robot companies, as it requires not only strong financial support but also a well-trained team to tackle the core algorithms of robot controllers and some challenging issues in robot kinematics. Given the current R&D capabilities of domestic companies and their understanding of industrial robots, very few can achieve self-development; even if some companies expend great effort to develop their own core controllers, their functions and performance still lag significantly behind those of foreign manufacturers.

The second method is to integrate development using third-party controllers. For example, customers can directly purchase robot controllers and teach pendants provided by companies like KEBA or B&R to integrate and develop their own industrial robots. This method has distinct characteristics: the R&D design risk is relatively low, and product release is relatively quick; however, it lacks significant competitive advantage in cost control, as the core technologies primarily come from these controller suppliers.

So, is there a solution for designing and implementing robot controllers that has low development risk while also being competitively cost-effective? The answer is yes, and it comes from our Phoenix Contact software’s industrial robot controller software solution. Next, let’s take a look at the architecture and features of this robot controller software solution.

Solution

1. System Architecture

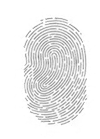

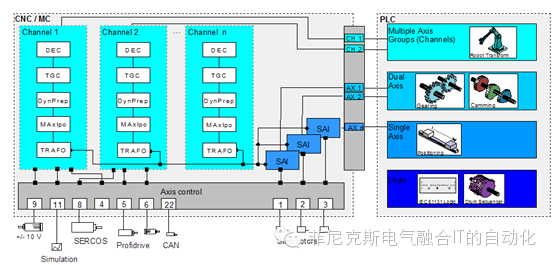

As shown in the figure below, the electrical software provides a high-performance robot motion control platform software based on IPC, including: real-time operating system, motion control core, and fieldbus technology, as well as an open PLC development software platform.

2. Features

High-performance IPC real-time motion control platform:

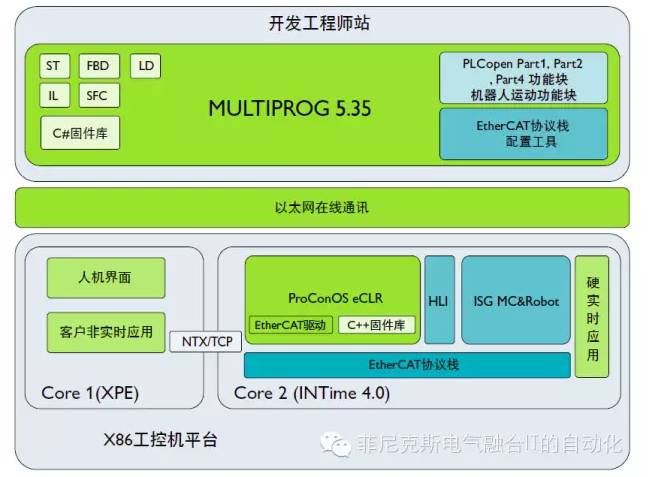

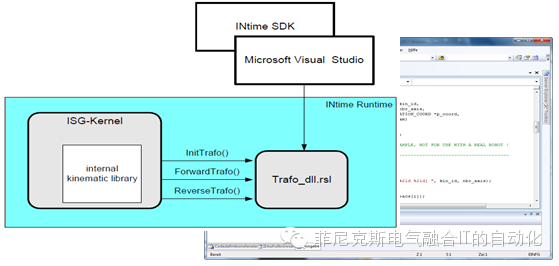

Based on the Windows real-time kernel INTime, it has very high stability and reliability, and application program development and maintenance are very simple. INTime can run various robot system software on a stable and reliable open platform.

Using PLC programming languages to control robot motion:

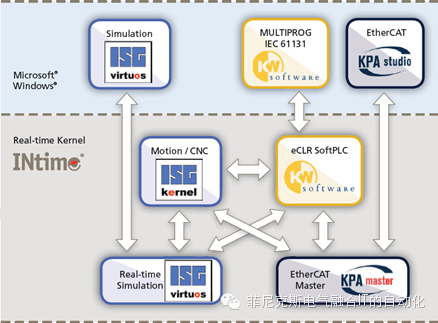

It adopts the IEC61131-3 international programming standard to control robot motion and logic, allowing programming in five languages: FBD, LD, ST, IL, and SFC. It supports algorithm function blocks that comply with the PLCopen Motion Control standard, providing standard control methods for robot applications.

The robot’s motor axes and external auxiliary axes can link up to 16 axes, supporting online 3D simulation and debugging.

Robot motion and trajectory:

The robot motion control core can support single-axis, electronic gear cam, and robot control, and supports multi-channel architecture, allowing multiple robots to work simultaneously.

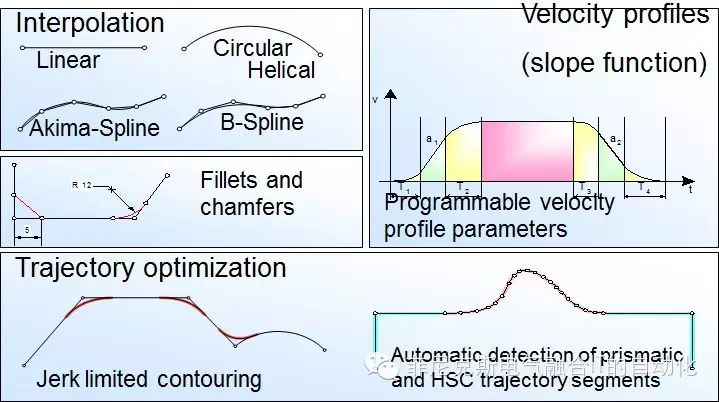

The motion control core supports different trajectory compensation, including line, arc, spline, and others. It supports S-shaped velocity curves and optimization between continuous trajectories.

Robot kinematics support:

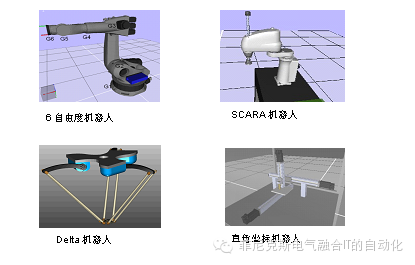

Currently supports commonly used robot structure kinematics templates, 6-degree of freedom robots, SCARA, Delta robots, and Cartesian coordinate robots.

Customers can use C/C++ to develop custom kinematic models:

Robot core extensibility:

With the open software platform architecture of Windows & INTime dual systems, using INTime and PLC development toolkits, customers can use C/C++ and PLC programming languages to extend the peripheral devices of the robot controller, such as teach pendants, vision modules, drive systems, and IO modules.

3. Summary

Phoenix Contact software provides the necessary open software platform for developing robot controllers. Customers can install the robot software package provided by Phoenix Contact on standard IPCs, leveraging high-performance and high-reliability software solutions to quickly conduct secondary development, thus rapidly launching controller products suitable for various robot structures.

Classic Review

How to Become a Pro in PLC Programming?

Easily Understand What Robot Vision Is and Its Applications!

Maintenance and Troubleshooting of Industrial Robots, Don’t Forget to Save!

Comparison of Offline Programming Software Functions and Drawbacks for Industrial Robots!

Mercedes-Benz’s Automated Production Line, All You Hear Are the Sounds of Robot Joints Turning…

How to Become an Industrial Robot Application Engineer, Click

▼

Industrial Robot Training….

Boosting “Made in China” Smart Manufacturing, Our Common Mission