Many technicians often encounter the following issue: why can’t my touch screen communicate with the PLC?

For example, here are two common problems:

1. Weintek touch screen cannot communicate with Siemens PLC, constantly indicating that the PLC is unresponsive. How should I set it up?

Solution Approach: Ensure that the baud rate, data bits, and stop bits are the same, and that the station numbers are not the same, meaning the PLC and touch screen addresses cannot be identical. Then, check if the communication line is functioning properly…

2. How to determine if there is a fault in communication between the touch screen and PLC through programming?

Solution Approach: A common method is to use heartbeat detection. Define a boolean variable, and the HMI will set this point at a fixed frequency. After the PLC receives this point as an ON signal, it will reset it. If the ON signal is not received within a certain period, such as 5 seconds, it is considered a communication interruption. The PLC sends the memory clock byte to the screen, and the screen uses a script to assign this byte’s value to another address within the PLC. The PLC then checks if the returned byte values are the same over two scan cycles; if they are, it indicates a communication interruption.

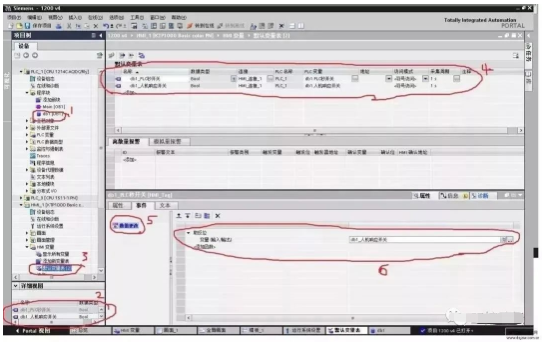

For example, see the diagram and follow these steps:

1. Create a DB1 data block in the PLC, containing two digital switches: “PLC Second Switch” and “HMI Response Switch”;

2. Connect these two variables in the HMI variables;

3. In the properties of the HMI “PLC Second Switch” variable, under events, add “Invert”, so that the “HMI Response Switch” variable changes with the “PLC Second Switch”;

4. In the PLC program block, program the “PLC Second Switch” to toggle every 0.5 seconds, and use the TON delay instruction to output “HMI Communication Failed” if the “HMI Response Switch” does not act within one second, because after a communication anomaly, the “HMI Response Switch” will no longer change.

Good tips, take them freely~

In fact, any issues with touch screens and PLC communication generally boil down to four questions:

(1) Are the PLC parameters consistent with those in the project?

(2) Is the communication line connected according to the wiring diagram?

(3) Is the COM port set in the project correctly connected to the screen?

(4) If the parameters and wiring are confirmed to be correct, check if there is an issue with the PLC program or PLC address.

1

First, check the parameters

Use the PLC programming software to connect to the PLC and test the parameters. Check if the parameters set in the project match the tested ones. Pay special attention to the following parameters:

(1) Communication port settings: Confirm whether the PLC is connected to the touch screen via COM1 or COM2;

(2) Device type: This is crucial; if the protocol is incorrectly selected, nothing else matters;

(3) Connection method: Ensure that the PLC and touch screen are connected via RS485 or RS232C;

(4) Interface parameters and PLC station number: Must match the settings in the PLC.

2

Online Simulation

Use our configuration software to connect the PLC to a computer with the PLC’s communication cable and perform online simulation to see if the project communicates properly. You can use a numeric input component or switch to operate it, and check if the previous operations are still present after turning off the simulator and then turning on the online simulation again. If NC is directly indicated (NC means that the previous operation was not written down, indicating no communication), the specific approach is as follows:

(1) Connect the PLC to the computer via RS232. Some PLCs have RS232 ports, while others do not; if not, an adapter can be used to connect to the computer.

(2) Create a simple project. Place two components: a numeric display and a numeric input. Set the address to the PLC’s internal address.

(3) Ensure that the project parameters match the settings in the PLC.

(4) Click on the online simulation function.

This method will clearly show whether the PLC can communicate with the PC. If communication is established, the issue can be ruled out from the PLC side and parameter settings.

3

Test the Wiring

Use a multimeter to test the wiring according to the wiring diagram. Confirm whether the RS485 and RS232C wiring is correct, as the wiring methods for touch screens and various PLCs differ. This can be referenced in the manual, which is a basic method for troubleshooting communication issues.

Source: Internet, copyright belongs to the original author. If there are any copyright issues, please contact us promptly for removal, thank you!

ZHINANCHE

Click “Read Original” to register and inquire about robot courses