For more in-depth information, reports, and knowledge about sensor technology, sensor testing technology, and IoT sensor technology, please follow the Sensor Expert WeChat public account and set it as a star to view past content.

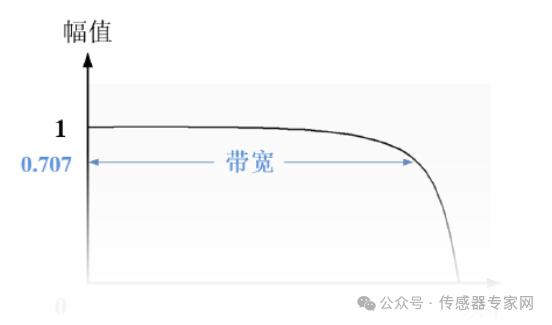

1. Bandwidth

Generally refers to the range of signals where the sensor output response decreases to the square root of one-half or half power of its maximum response. In simpler terms, it is the range that the sensor can sample. The indicator of the sensor’s response range to external signals is its bandwidth, mainly describing the dynamic characteristics of the sensor (whether it can keep up with the measurement changes frequency), and effective bandwidth refers to the bandwidth that the sensor can actually guarantee measurement accuracy. The bandwidth here is actually described from the frequency domain. In other words, this aspect is essentially the same as frequency response, which is the sensor’s ability to react to external signals! From the perspective of the transfer function, most sensors can be simplified to a first or second-order element.

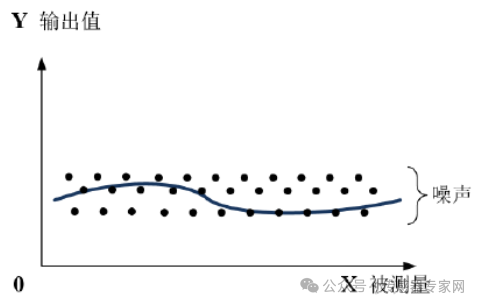

2. Sensitivity

Sensitivity refers to the ratio of the change in sensor output △y to the change in input △x under steady-state operation.

Generally, within the linear range of the sensor, higher sensitivity usually means a higher signal-to-noise ratio, corresponding to a larger output signal value for the measured change, which is more beneficial for signal processing. However, it is important to note that a high sensitivity in sensors may easily mix in irrelevant external noise, which is then amplified by the system, affecting measurement accuracy. Therefore, it is required that the sensor itself should have a high signal-to-noise ratio to minimize interference signals introduced from outside.

3. Zero Drift

Zero drift occurs when the input value of the sensor is zero, but its output value changes to a certain extent. Temperature drift is the most common factor causing zero drift. Causes of zero drift include: aging of sensitive components, stress, charge leakage, temperature changes, etc.

4. Resolution

Resolution refers to the smallest change that the sensor can detect within a specified measurement range. For example, a meter can only measure distances at a millimeter level, while a micrometer can detect at a 1/‰ millimeter level. Resolution has a unit of absolute value. For instance, if the resolution of a temperature sensor is 0.1 degrees Celsius with a full scale of 500 degrees Celsius, then its resolution is 0.1/500=0.02%.

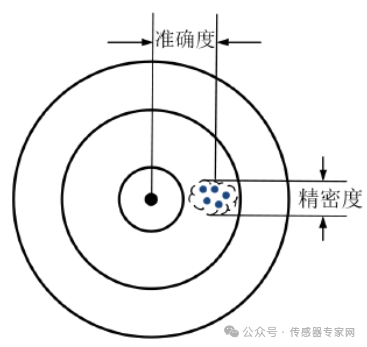

5. Accuracy

Accuracy refers to the value within three standard deviations around the true value relative to the range, which indicates the difference between the measured value and the true value. If the measurement goal is qualitative analysis, sensors with high repeatability should be chosen, but absolute precision sensors should not be selected. If the measurement aims to obtain quantitative analysis results, sensors with accuracy that meets the requirements must be chosen.

(1) Causes of systematic errors: inherent errors of measurement principles and algorithms, inaccurate calibration, environmental temperature influence, material defects, etc.; (2) Causes of random errors: transmission gaps, component aging, etc.

6. Repeatability

The repeatability of a sensor refers to the difference between measurement results when repeated multiple times in the same direction under the same conditions. Also known as repeat error, reproducibility error, etc. The smaller the repeatability error, the better the repeatability and stability of the sensor.

7. Frequency Response Characteristics

The frequency response characteristics of the sensor determine the frequency range of the measurement, which must remain distortion-free within the allowed frequency range. In fact, there is always a certain delay in the sensor’s response, and a shorter delay time is preferable. Sensors with high frequency response can measure signals over a wide frequency range, but due to structural characteristics, mechanical systems have large inertia, so sensors with low frequency response can only measure lower frequency signals.

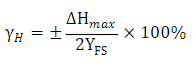

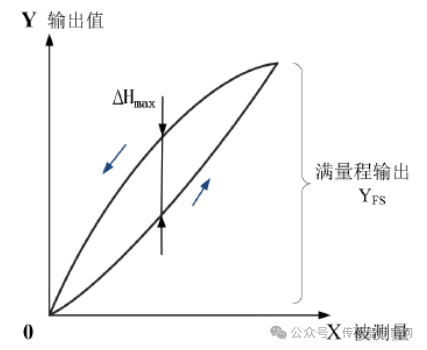

8. Hysteresis

Simply put, hysteresis is the inconsistency of the input-output mapping curve of the sensor when inputting in the forward and reverse directions. Causes of hysteresis include: material characteristics of sensitive components, mechanical structural characteristics (friction, transmission gaps, etc.), etc.

9. Linear Range

The linear range of a sensor refers to the range where output is proportional to input. Theoretically, within this range, sensitivity remains constant, and the wider the linear range of the sensor, the larger its measurement range. However, in reality, no sensor can be absolutely linear; its linearity is relative. When the required measurement accuracy is relatively low, sensors with small non-linear errors can be considered linear within a certain range, which facilitates measurement.

10. Sampling Frequency

Sampling frequency refers to the number of measurement results that the sensor can sample in a unit time, reflecting the sensor’s rapid response capability. Sampling frequency is a technical indicator that must be fully considered when measuring rapidly changing data.

As the sampling frequency changes, the accuracy metrics of the sensor also vary. Generally speaking, the higher the sampling frequency, the lower the measurement accuracy. However, the accuracy provided by the sensor is often obtained under the sampling speed or even under static conditions. Therefore, when selecting sensors, both accuracy and speed must be considered simultaneously.

Starred content = content that matters to you, according to the recommendation principles of WeChat public accounts, if not set as a star on the Sensor Expert public account homepage, you will not be able to receive the latest information in the sensor industry in a timely manner!

Source: Electric Control Technology Master

Statement:Reprinting this article is for the purpose of conveying more information. If there are any source attribution errors or infringement of your legal rights, please contact us, and we will promptly correct or delete it. Thank you.

-

China’s Sensors Depend on You! Summary of Sensor Research Information from 30 Top Universities -

Finally Understood, Modern Warfare is All About Sensors -

China’s Chip Tycoon Comes from Sensors -

Woke Up to Find Chinese Companies Can’t Design Sensors?!