The 3D printing technology, in a narrow sense, mainly refers to additive manufacturing technology, which is a cutting-edge technology that integrates digital modeling technology, mechatronics control technology, information technology, material science, and chemistry. It is hailed as the core technology of the “Third Industrial Revolution”. From the perspective of forming processes, 3D printing breaks through traditional forming methods by eliminating the need to first create molds and mechanical processing. By combining rapid automatic forming hardware systems with CAD software models, it can manufacture products of various complex shapes, significantly shortening the design and production cycle and greatly reducing production costs.

Next, I will introduce them one by one:

3D printing is typically implemented using digital technology material printers.

1) Advanced design software and digital tools assist designers in creating three-dimensional digital models of products and automatically analyze the printing process based on the model, automatically controlling the direction of the printer.

2) Precision machinery: 3D printing technology uses “layer-by-layer stacking” as a processing method, requiring high precision in production, necessitating high accuracy and stability of the printing equipment.

Based on differences in forming principles, we will mainly introduce several commonly used 3D printing technologies:

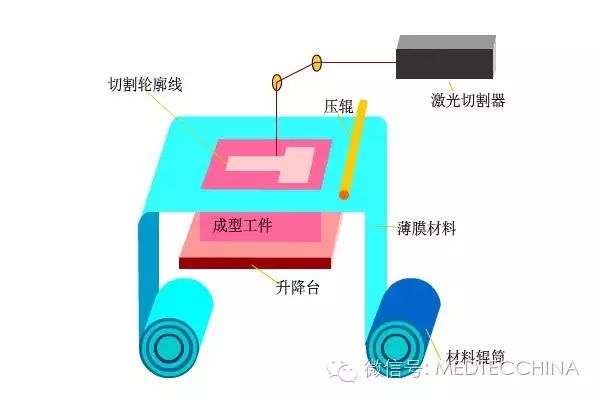

Layered solid forming technology (LOM) is the oldest 3D printing forming technology. LOM technology primarily uses paper materials, PVC films, etc., which are inexpensive and have high forming precision. The basic principle of LOM technology is shown in the figure below.

(1) The layered solid forming system mainly includes a computer, numerical control system, raw material storage and transport components, thermal adhesive pressing components, laser cutting systems, and a liftable workbench.

(2) The computer is responsible for receiving and storing the three-dimensional model data of the forming workpiece, which is a series of cross-sectional profiles extracted along the height direction of the model. The raw material storage and transport components gradually deliver the stored raw materials (film materials coated with adhesive on the bottom) to the workbench.

(3) The laser cutter cuts the film along the profile line of the workpiece cross-section, and the liftable workbench supports the forming workpiece, lowering by one material thickness after each layer is formed to allow for the next layer of material to be glued and cut. Finally, the thermal adhesive pressing components will layer by layer bond the film in the forming area together, repeating the above steps until the workpiece is fully formed.

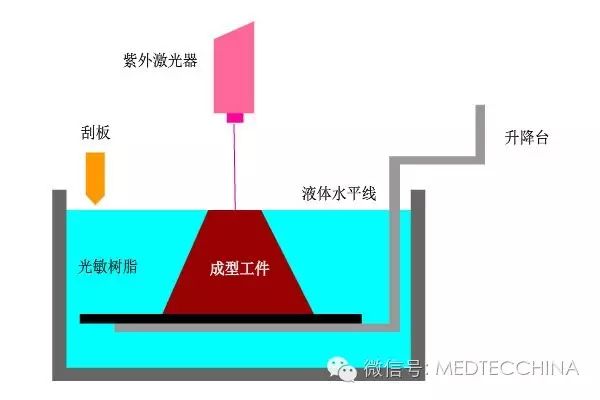

Stereolithography (SLA) is currently the most researched, mature, and widely used 3D printing technology in the world. The SLA process uses photo-sensitive resin as the material, and under system control, a UV laser scans the liquid photo-sensitive resin to solidify it layer by layer, allowing for the production of highly precise geometric models in a simple and fully automated manner. The basic principle of SLA technology is shown in the figure below:

(1) The liquid tank is first filled with liquid photo-sensitive resin, and a helium-cadmium laser or argon ion laser emits a UV laser beam, which is controlled by a computer to scan the surface of the liquid photo-sensitive resin according to the layered cross-sectional data of the workpiece, causing the resin in the scanned area to undergo polymerization and solidification, forming a thin layer of the workpiece.

(2) Once a layer of resin is cured, the workbench will move down by a layer thickness to cover a new layer of liquid resin over the previously cured resin. A blade will smooth the viscous resin surface before proceeding to the next layer of laser scanning and curing. Due to the high viscosity of the liquid resin, it leads to poor flowability, making it difficult for the liquid surface to quickly level after curing each layer, which will affect the forming accuracy of the entity. The resin will be evenly spread over the previous layer after being leveled by the blade, allowing for better precision after laser curing and a smoother surface of the formed workpiece.

(3) The newly cured layer will firmly bond to the previous layer, repeating until the entire workpiece is stacked, resulting in a complete three-dimensional model.

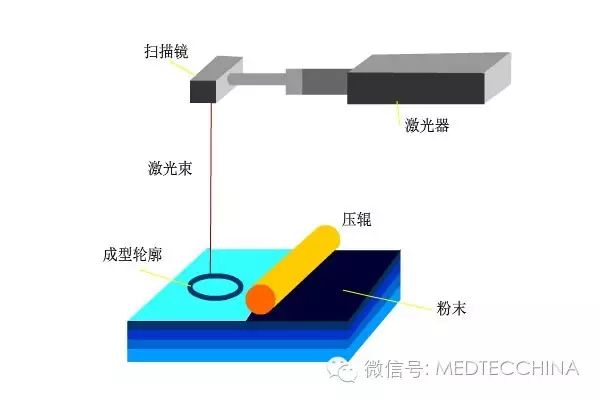

Selective Laser Sintering (SLS): The SLS process uses powder materials, where a laser scans and irradiates the powder under computer control to achieve sintering and bonding of the material, thus forming layer by layer. The principle of SLS forming is shown in the figure below:

(1) A roller first spreads a layer of powder over the upper surface of the already formed workpiece, and the numerical control system controls the laser beam to scan and irradiate the powder layer according to the cross-sectional profile, raising the temperature of the powder to the melting point, thus achieving sintering and bonding with the already formed part below.

(2) Once a layer cross-section is sintered, the workbench will lower by one layer thickness, and the roller will again evenly spread a layer of powder on top to begin the sintering of a new layer cross-section, repeating this operation until the workpiece is fully formed.

(3) During the forming process, the unsintered powder supports the cavities and cantilevers of the model, thus SLS-formed workpieces do not require support structures like SLA-formed workpieces. The materials used in SLS are relatively abundant compared to SLA, mainly including wax, polycarbonate, nylon, fine nylon, synthetic nylon, ceramics, and even metals.

(4) After the workpiece is fully formed and completely cooled, the workbench will rise to its original height, and the workpiece needs to be removed, using a brush or compressed air to remove the excess powder from the model’s surface.

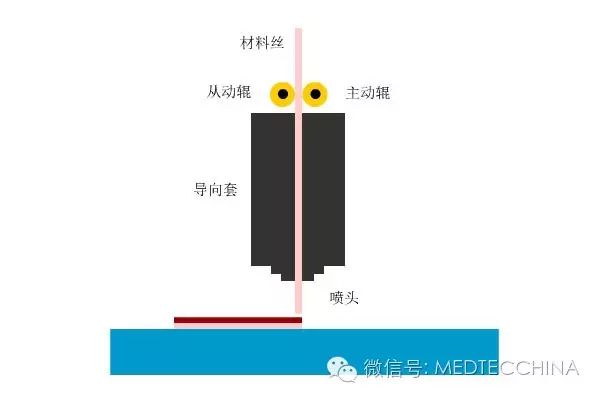

Fused Deposition Modeling (FDM) uses filamentous thermoplastic materials that are heated and melted, extruded through a nozzle by an extruder. The molten filament is immediately bonded with the previous layer of material. After one layer is deposited, the workbench will lower by a predetermined increment, and the above steps will be repeated until the workpiece is fully formed. The detailed technical principle of FDM is as follows:

(1) The thermoplastic filament (usually ABS or PLA material) is first wound on a feed roller, driven by a stepper motor that rotates the roller. The filament is fed to the extruder nozzle due to the friction between the active roller and the passive roller. There is a guiding sleeve between the feed roller and the nozzle, made of low-friction material to ensure that the filament can smoothly and accurately reach the interior of the nozzle.

(2) Above the nozzle is a resistive heating wire, which heats the filament to a molten state under the action of the heater. The material is then extruded onto the workbench, and upon cooling, it forms the cross-sectional profile of the workpiece.

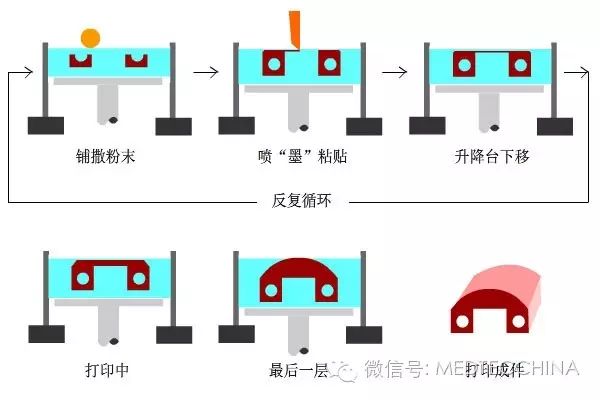

Three-Dimensional Printing (3DP) works similarly to inkjet printers, and has similarities with the SLS process, using powder materials such as ceramics, metals, and plastics. However, unlike SLS, 3DP does not bond the powders through laser sintering, but rather prints the cross-section of the workpiece by spraying adhesive layer by layer, as shown in the figure below:

First, the device will level the powder in the working tank, and then the nozzle will spray liquid adhesive (such as silicone) onto the specified areas of the pre-layered powder, continuously repeating these steps until the workpiece is fully formed, after which the excess powder material can be removed. The 3DP technology has a very fast forming speed, suitable for manufacturing structurally complex workpieces, and is also applicable to the production of composite materials or non-homogeneous material parts.

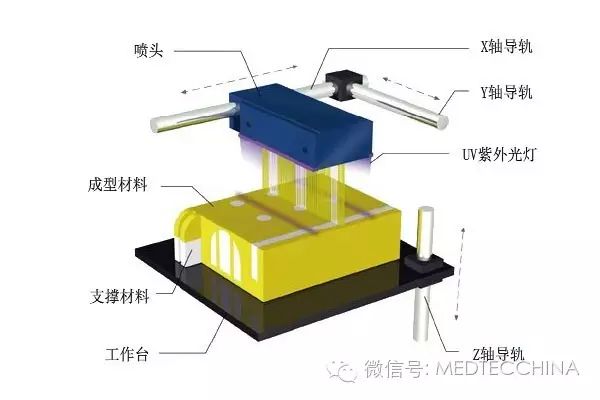

PolyJet technology is also one of the most advanced 3D printing technologies today. It is somewhat similar to 3DP, but instead of spraying adhesive, it sprays polymer forming materials, as shown in the figure below:

(1) The PolyJet print head moves back and forth along the X-axis, and its working principle is very similar to that of an inkjet printer. The difference is that the print head sprays not ink but photo-sensitive polymers. When the photo-sensitive polymer material is sprayed onto the workbench, a UV lamp emits UV light along the direction of the print head to cure the photo-sensitive polymer material.

(2) After completing one layer of spray printing and curing, the built-in workbench of the device will precisely lower by one forming layer thickness, and the print head will continue to spray the photo-sensitive polymer material for the next layer of printing and curing. This continues layer by layer until the entire workpiece is completed.

As mentioned earlier, compared to traditional manufacturing technologies, 3D printing does not require the prior manufacturing of molds, does not need to remove a large amount of material during the manufacturing process, and does not require complex forging processes to achieve the final product. Therefore, it can achieve structural optimization, save materials, and conserve energy in production. 3D printing technology is suitable for new product development, rapid single-piece and small batch part manufacturing, manufacturing of complex-shaped parts, design and manufacturing of molds, and is also applicable for manufacturing difficult-to-process materials, shape design verification, assembly inspection, and rapid reverse engineering.

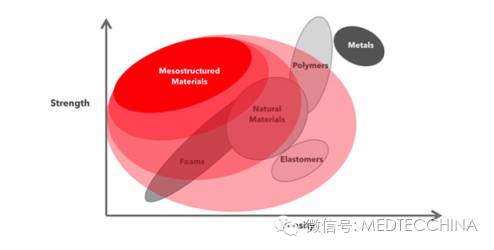

In addition, in material synthesis, compared to traditional methods, 3D printing will achieve greater flexibility and effectiveness. This is a new area for the future development of 3D printing.

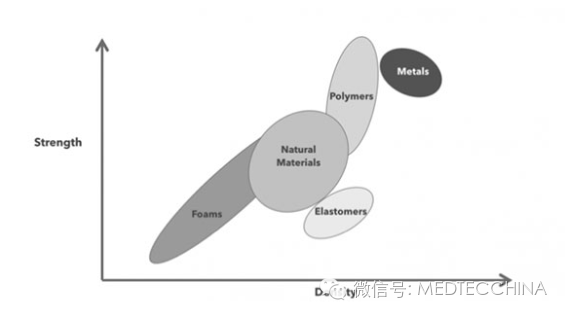

Traditional:

3D printing:

The common goal of 3D printing is to achieve the printing of various composite materials from a single machine, achieving multiple manufacturing attributes for the project at once. However, micro-structured material technology allows us to obtain more value beyond single materials. Compared to relying on different materials for different properties, designers can use micro-structured material technology to create an object with all the desired performance characteristics.

(1) 3D products are difficult to replicate in bulk. 3D printing has unique features in personalized and even small-scale production, but it cannot achieve mass production.

(2) The production process is relatively complex, especially for products with complex structures, requiring the collection of various structural information and calibration of printing equipment.

(3) Material breakthroughs. 3D printing can be applied to many scenarios, but compared to traditional manufacturing processes, the materials and printing technology do not have advantages, which require better collaboration in the industry.

(4) High costs; non-replicability is also an important reason for cost increases. The technical standards and policy systems are not perfect, and the education and training systems urgently need to be strengthened, with a lack of professional talent.

(5) Practicality is weak; for some products, it is often only possible to print the outer shell or prototype, without all the functions of the final product.

As a rapid prototyping machine, 3D printing is used to complete the lowest common parts of various manufacturing projects. The result is that these machines can do many things, but do very few well. This is not due to special materials or overly advanced and complex controls. The real constraint on the innovation of 3D printing technology is our perspective on these technologies: viewing them only as single-component manufacturing, lacking a systematic approach.

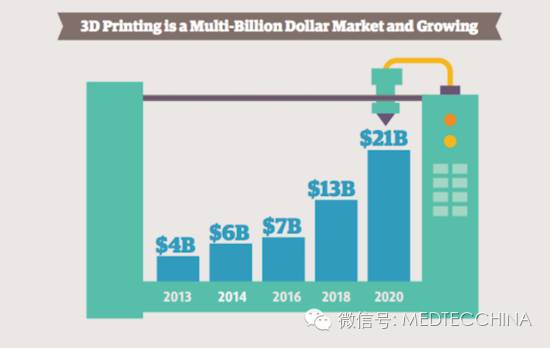

The Consumer Technology Association (CTA) in the United States and United Parcel Service (UPS) recently released a report titled “3D Printing: The Next Revolution in Industrial Production,” predicting that the market revenue will double to $21 billion over the next four years. Last year, the 3D printing market value grew by 30%.

The 3D printing industry is expected to reach a market value of $7.3 billion this year, including printing machines, materials, and printing services. By 2020, the industry is expected to reach a value of $21 billion. The consumer electronics and automotive industries will drive 40% growth in the 3D printing industry, while medical devices will drive a 15% increase. For example, 98% of hearing aids globally are manufactured using 3D printing technology.

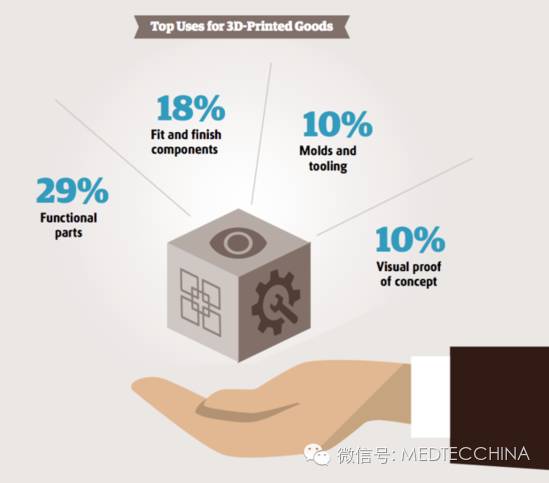

The report states that currently, two-thirds of manufacturers are using 3D printing technology to some extent, and 25% of manufacturers plan to adopt this technology in the future. The main reasons for companies adopting 3D printing technology include: prototyping (25%), product development (16%), and innovation (11%).

Early adopters of 3D printing technology mainly utilized it for prototyping. In fact, 3D printing accounts for only 0.04% of the global manufacturing market, and prototyping is the most common use. Research firm Wohlers Associates believes that 3D printing technology will eventually account for 5% of the global manufacturing market, representing a huge opportunity of $640 billion.

From an application perspective, the number of patent applications related to 3D printing has surged over 800% in the past decade, and the number of patents granted has also increased significantly. Currently, 3D printing accounts for only 0.04% of the global manufacturing market, which is significantly lower compared to the trillion-dollar manufacturing market.

However, compared to high-efficiency mass standardized production, 3D printing has its own advantages, as it can achieve customization and even produce personalized products at the same cost, bringing more personal value to consumers (without price reductions due to product scaling). In areas of customization, personalization, and complexity where there is no profit margin in mass production, 3D printing can shine. In the future, 3D printing can create strong product categories in fields with strong customization demands such as fashion, aerospace, healthcare, and food.

From a long-term perspective, 3D printing will bring us decentralized production tools, and decentralized social collaboration will again become the theme. The future we face is an era of personalized and socialized creation. 3D printing will create a brand new category of powerful products, eliminating dependence on complex supply chains and excessive waste while decentralizing production, wealth, and knowledge potential. 3D printing can help establish a decentralized, self-sufficient economy characterized by the close integration of production and consumption.