Qicheng Automation Pragmatic + Reliable automation training service provider

-

Training Projects:PLC System Integration + Motion Control + Robotics + Machine Vision

Providing professional automation project implementation and system integration services

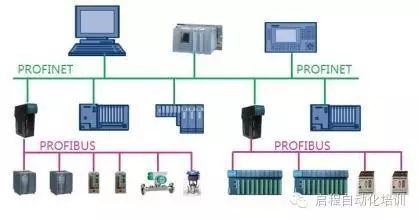

Simply put, PROFINET = PROFIBUS + Ethernet, transferring the master-slave structure of PROFIBUS to Ethernet. Therefore, PROFINET will have Controllers and Devices, and their relationship can be simply compared to the Master and Slave of PROFIBUS. Of course, there are differences, but this analogy helps in understanding. Additionally, since PROFINET is based on Ethernet, it can have star, tree, and bus topologies, while PROFIBUS only has a bus topology. Thus, PROFINET is a product that combines the master-slave structure of PROFIBUS with the topological structure of Ethernet. Other features like real-time performance touted by Siemens are also present in Ethernet; however, PROFINET can enhance the precision of real-time performance due to the presence of a controlling unit like the Controller.

PROFINET is a new Ethernet communication system developed by Siemens and the PROFIBUS User Organization. PROFINET has the capability to communicate between multi-vendor products, automation, and engineering modes, and is optimized for distributed intelligent automation systems. Its application results can significantly reduce configuration and debugging costs. The PROFINET system integrates PROFIBUS-based systems, providing protection for existing system investments. It can also integrate other fieldbus systems. PROFINET is an advanced communication system supporting distributed automation. In addition to communication capabilities, PROFINET also includes specifications for the concept of distributed automation, which is based on vendor-independent objects and connection editors, as well as XML device description language. Ethernet TCP/IP is used for communication between smart devices where timing requirements are not strict. All strictly time-critical real-time data is transmitted via the targeted PROFIBUS DP technology, and data can be integrated into the PROFINET system from the PROFIBUS DP network through a proxy. PROFINET is the only bus that uses existing IT standards without defining its own dedicated industrial application protocol. Its object model is based on Microsoft’s Component Object Model (COM) technology. The interaction between all distributed objects on the network uses Microsoft’s DCOM protocol along with standard TCP and UDP protocols.

PROFINET is a new Ethernet communication system developed by Siemens and the PROFIBUS User Organization. PROFINET has the capability to communicate between multi-vendor products, automation, and engineering modes, and is optimized for distributed intelligent automation systems. Its application results can significantly reduce configuration and debugging costs. The PROFINET system integrates PROFIBUS-based systems, providing protection for existing system investments. It can also integrate other fieldbus systems. PROFINET is an advanced communication system supporting distributed automation. In addition to communication capabilities, PROFINET also includes specifications for the concept of distributed automation, which is based on vendor-independent objects and connection editors, as well as XML device description language. Ethernet TCP/IP is used for communication between smart devices where timing requirements are not strict. All strictly time-critical real-time data is transmitted via the targeted PROFIBUS DP technology, and data can be integrated into the PROFINET system from the PROFIBUS DP network through a proxy. PROFINET is the only bus that uses existing IT standards without defining its own dedicated industrial application protocol. Its object model is based on Microsoft’s Component Object Model (COM) technology. The interaction between all distributed objects on the network uses Microsoft’s DCOM protocol along with standard TCP and UDP protocols.

In the PROFINET concept, devices and plants are divided into technical modules, each module includes mechanical, electronic, and application software. The application software of these components can be developed using dedicated programming tools and downloaded to the relevant controllers. This dedicated software must implement the PROFINET component software interface and export the PROFINET object definitions as XML language. XML files are used to input vendor-independent PROFINET connection editors to generate PROFINET elements. The connection editor defines the exchange operations between PROFINET elements on the network. Ultimately, the connection information is downloaded to PROFINET devices via Ethernet TCP-IP.

In the PROFINET concept, devices and plants are divided into technical modules, each module includes mechanical, electronic, and application software. The application software of these components can be developed using dedicated programming tools and downloaded to the relevant controllers. This dedicated software must implement the PROFINET component software interface and export the PROFINET object definitions as XML language. XML files are used to input vendor-independent PROFINET connection editors to generate PROFINET elements. The connection editor defines the exchange operations between PROFINET elements on the network. Ultimately, the connection information is downloaded to PROFINET devices via Ethernet TCP-IP.

PROFINET (Real-time Ethernet) is based on industrial Ethernet, has very good real-time performance, and can directly connect field devices (using PROFINET IO), supporting a distributed automation control method (PROFINET CBA, equivalent to communication between master stations).

When Ethernet is applied to industrial control situations, it becomes industrial Ethernet after improvements for use in industrial sites.

If you have ever used Siemens network cards CP343-1 or CP443-1 for communication, you may have used protocols such as ISO or TCP connections. The TCP and ISO used here are protocols applied in industrial Ethernet. PROFINET is also a protocol in Siemens SIMATIC NET, specifically, it is a collection of many protocols, including real-time protocols like PROFINET IO RT, CBA RT, IO IRT, etc.

Therefore, PROFINET and industrial Ethernet cannot be compared; it can only be said that PROFINET is a real-time protocol running on industrial Ethernet. However, it is often said that some networks are PROFINET networks, simply because the PROFINET protocol is applied on that network.

Course Consultation: Beautiful WeChat

Long press the QR code to follow the personal WeChat of Qicheng Beauty